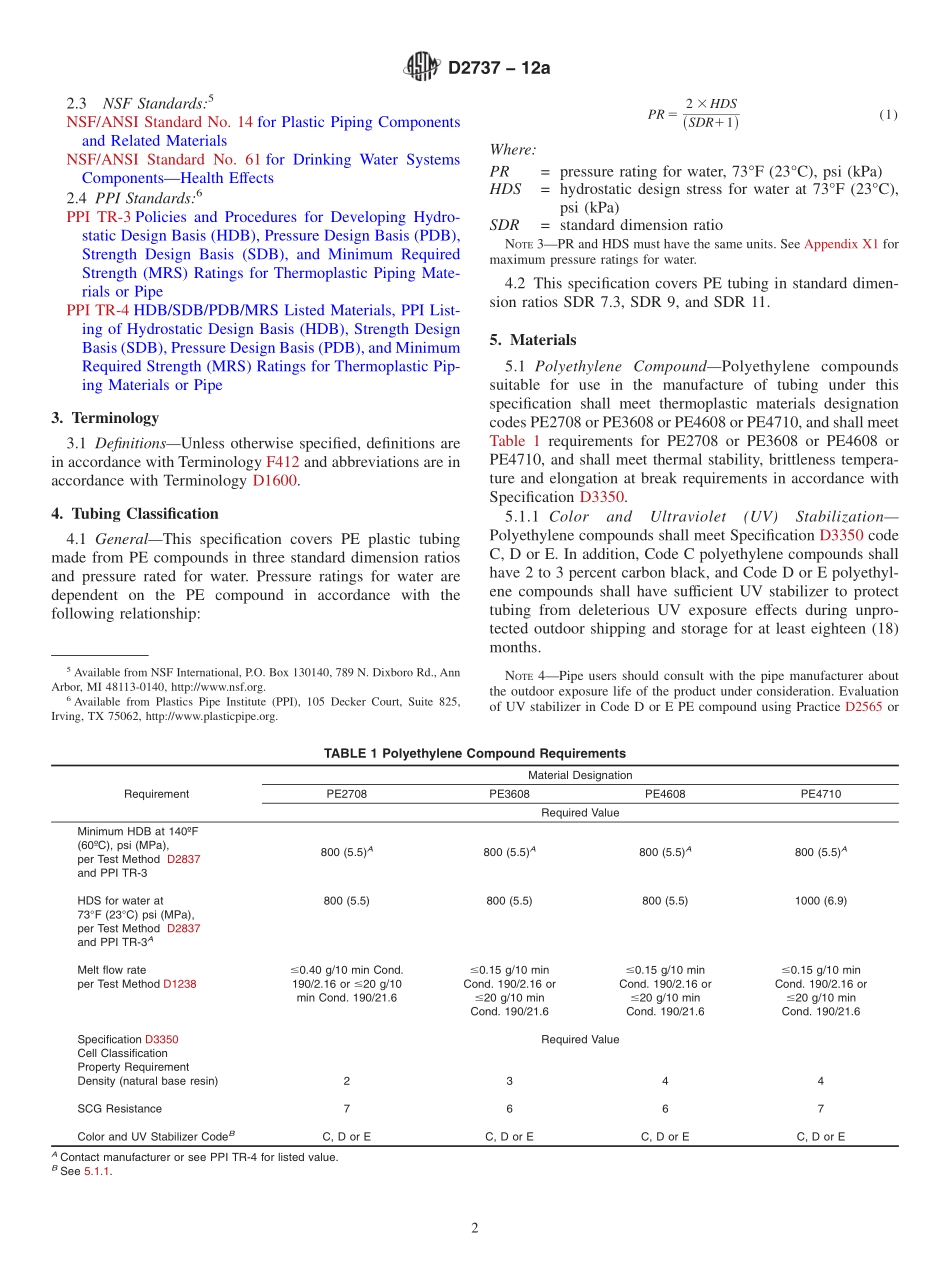

Designation:D2737−12aStandardSpecificationforPolyethylene(PE)PlasticTubing1ThisstandardisissuedunderthefixeddesignationD2737;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thisspecificationcoverspolyethylene(PE)plastictub-inginoutsidediametersandSDR’sthatarepressureratedforwater.IncludedarerequirementsforPEcompounds,andrequirementsandtestmethodsforPEplastictubingworkmanship,dimensions,elevatedtemperaturesustainedpressure,burstpressureandmarking.1.2Thetextofthisspecificationreferencesnotes,footnotes,andappendixeswhichprovideexplanatorymaterial.Thesenotesandfootnotesshallnotbeconsideredasrequirementsofthespecification.Notesandfootnotesintablesandfigures,andSupplementaryRequirementsarerequirementsofthespecifi-cation.1.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.NOTE1—JoiningPEplastictubingwithfittingsthatrequireflaringthetubingisnotrecommendedbecausePracticeD3140,thetechniqueusedtomaketheflarehasbeenwithdrawn(discontinued).NOTE2—ReferencesandPEcompounddescriptionsforPE2305,PE2406,PE3306,PE3406,andPE3408havebeenremovedduetochangesinSpecificationD3350andPPITR-3.Forremoveddesignations,refertopreviouseditionsofSpecificationD2737,SpecificationD3350,PPITR-3andPPITR-4.TheremovalofthesePEcompoundsdoesnotaffectpipelinesthatareinservice.PEcompoundsandmaterialdesigna-tionsresultingfromchangesinSpecificationD3350andPPITR-3areaddressedinSection5.1.4Thefollowingsafetyhazardscaveatpertainsonlytothetestmethodsportion,Section7,ofthisspecification:Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityofthe...