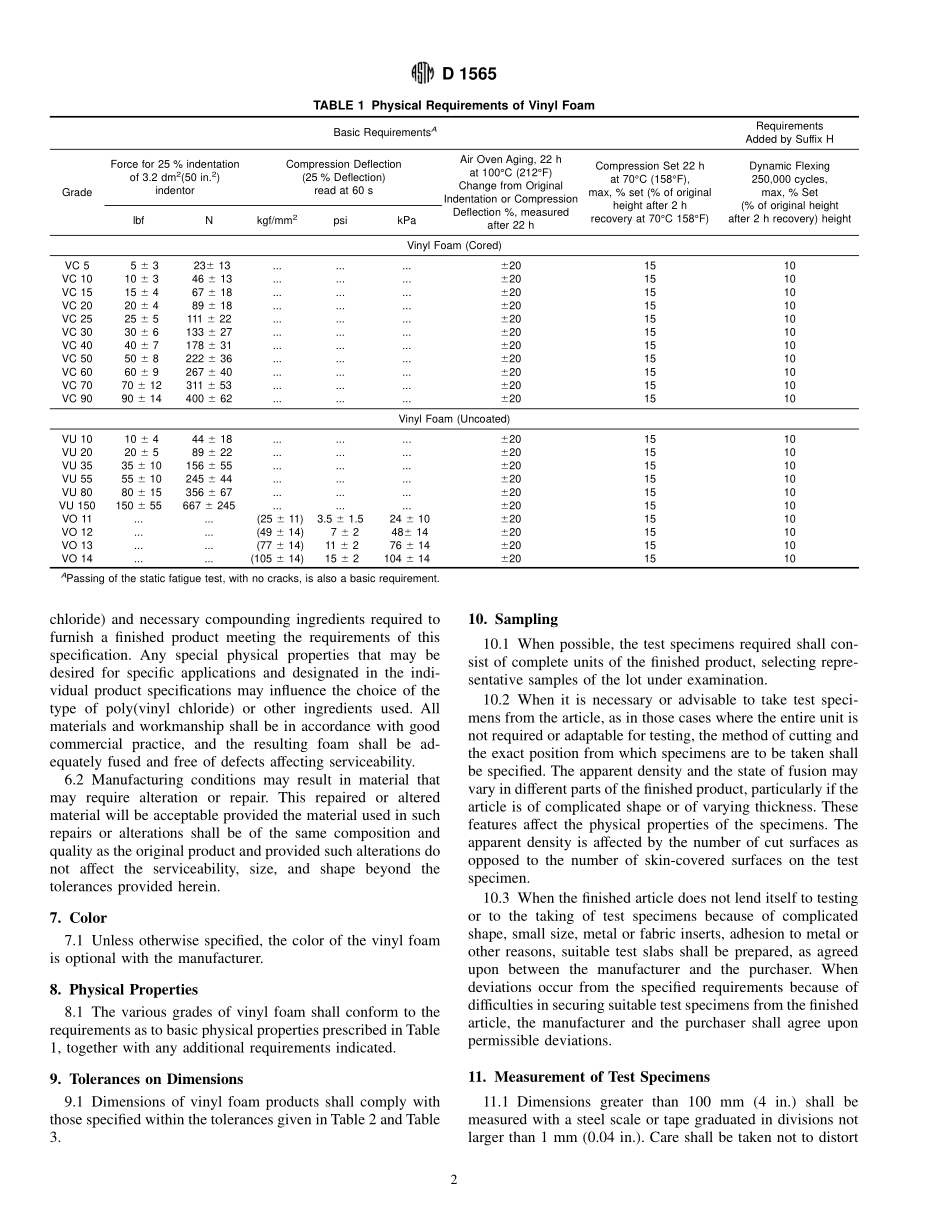

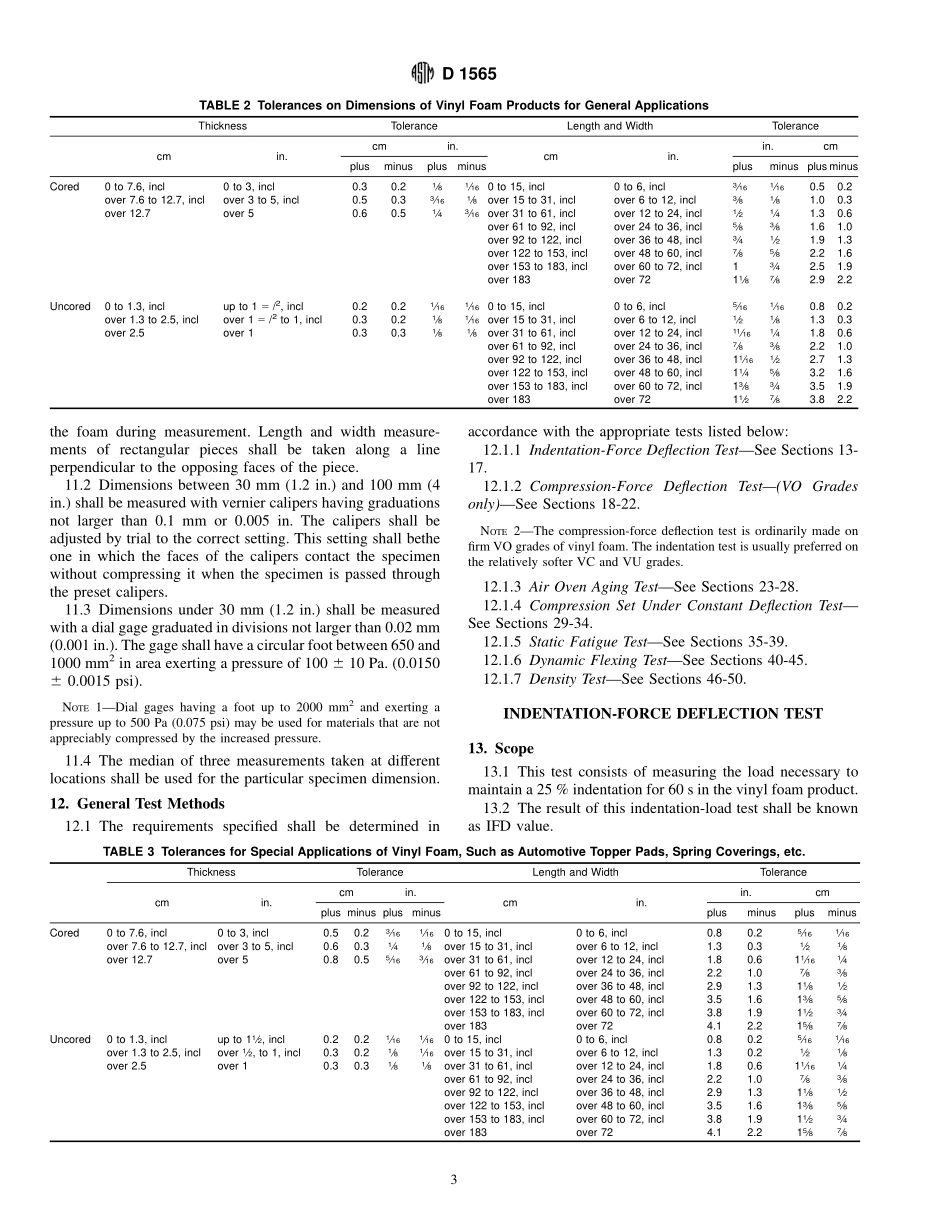

Designation:D1565–81(Reapproved1990)StandardSpecificationforFlexibleCellularMaterials—VinylChloridePolymersandCopolymers(Open-CellFoam)1ThisstandardisissuedunderthefixeddesignationD1565;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.ThisspecificationwaspreparedjointlybytheAmericanSocietyforTestingandMaterialsandtheSocietyofthePlasticsIndustry.1.Scope1.1Thisspecificationcoversflexiblecellularproductscon-taininginterconnectingcellsmadeofabasematerialknownaspoly(vinylchloride)orcopolymersthereof.1.2Itisintendedasageneralspecificationandmayneedtobesupplementedbydetailedspecificationsormethodsoftestforaparticularproduct,inwhichcasethelatterwouldtakeprecedence.Referencetomethodsfortestingpoly(vinylchlo-ride)foamproductsshouldspecificallystatetheparticulartestortestsdesired.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyproblems,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:E145SpecificationforGravity-ConvectionandForced-VentilationOvens23.DescriptionofTermsSpecifictoThisStandard3.1vinylorPVC—abbreviatedtermsusedtodesignatepoly(vinylchloride)orcopolymersthereof.3.2surfaceskin—thesmoothskinonafoamformedduringmanufacturebycontactwiththemold,coverplate,orair.3.3mechanicallyblownfoam—afoammadebymechani-callymixingagasintoabasematerialsoastodevelopafoamstructure.3.4chemicallyblownfoam—afoammadebyincorporatingachemicalagentintothebasematerialwhichonheatingliberatesagascausingfoamingofthebasematerials.3.5flexible—adescriptivetermappliedtoacellularorganicpolymericmaterialthatwillnotrupturewithin60swhenaspecimen200by25by25mmi...