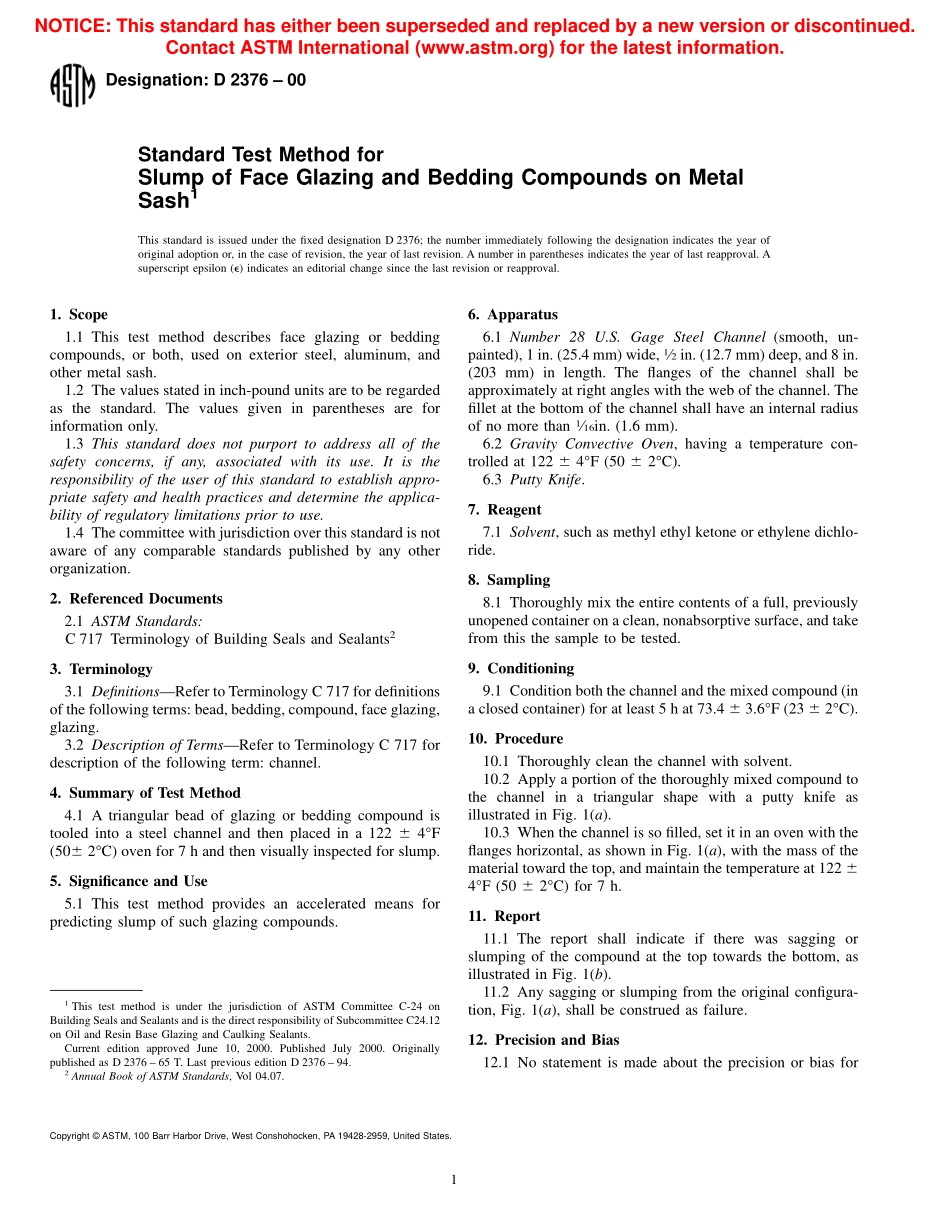

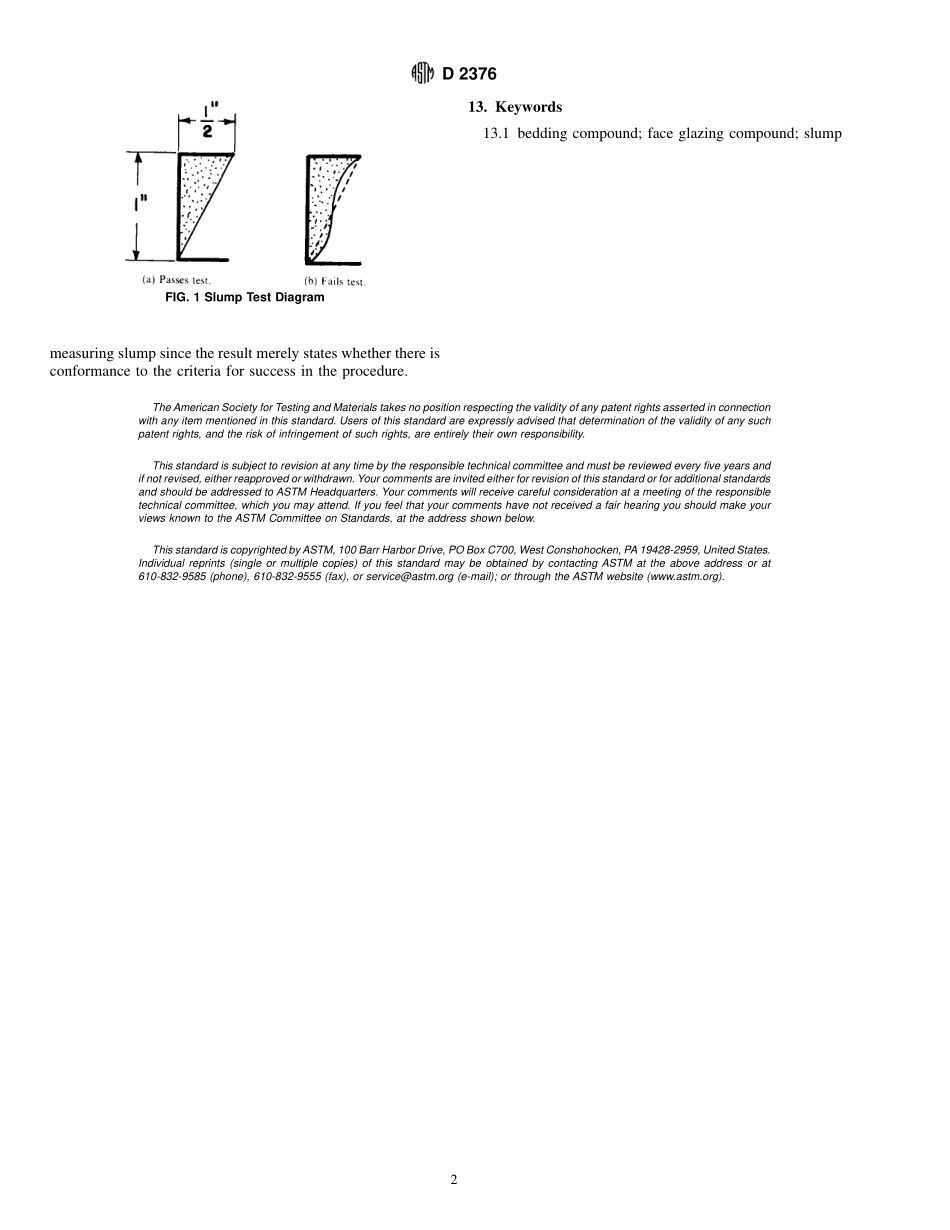

Designation:D2376–00StandardTestMethodforSlumpofFaceGlazingandBeddingCompoundsonMetalSash1ThisstandardisissuedunderthefixeddesignationD2376;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethoddescribesfaceglazingorbeddingcompounds,orboth,usedonexteriorsteel,aluminum,andothermetalsash.1.2Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.1.4Thecommitteewithjurisdictionoverthisstandardisnotawareofanycomparablestandardspublishedbyanyotherorganization.2.ReferencedDocuments2.1ASTMStandards:C717TerminologyofBuildingSealsandSealants23.Terminology3.1Definitions—RefertoTerminologyC717fordefinitionsofthefollowingterms:bead,bedding,compound,faceglazing,glazing.3.2DescriptionofTerms—RefertoTerminologyC717fordescriptionofthefollowingterm:channel.4.SummaryofTestMethod4.1Atriangularbeadofglazingorbeddingcompoundistooledintoasteelchannelandthenplacedina12264°F(5062°C)ovenfor7handthenvisuallyinspectedforslump.5.SignificanceandUse5.1Thistestmethodprovidesanacceleratedmeansforpredictingslumpofsuchglazingcompounds.6.Apparatus6.1Number28U.S.GageSteelChannel(smooth,un-painted),1in.(25.4mm)wide,1⁄2in.(12.7mm)deep,and8in.(203mm)inlength.Theflangesofthechannelshallbeapproximatelyatrightangleswiththewebofthechannel.Thefilletatthebottomofthechannelshallhaveaninternalradiusofnomorethan1⁄16in.(1.6mm).6.2GravityConvectiveOven,havingatemperaturecon-trolledat12264°F(5062°C).6.3PuttyKnife.7.Reagent7.1Solvent,suchasmethylethylketoneorethylenedichlo-ride.8.Sampling8.1Th...