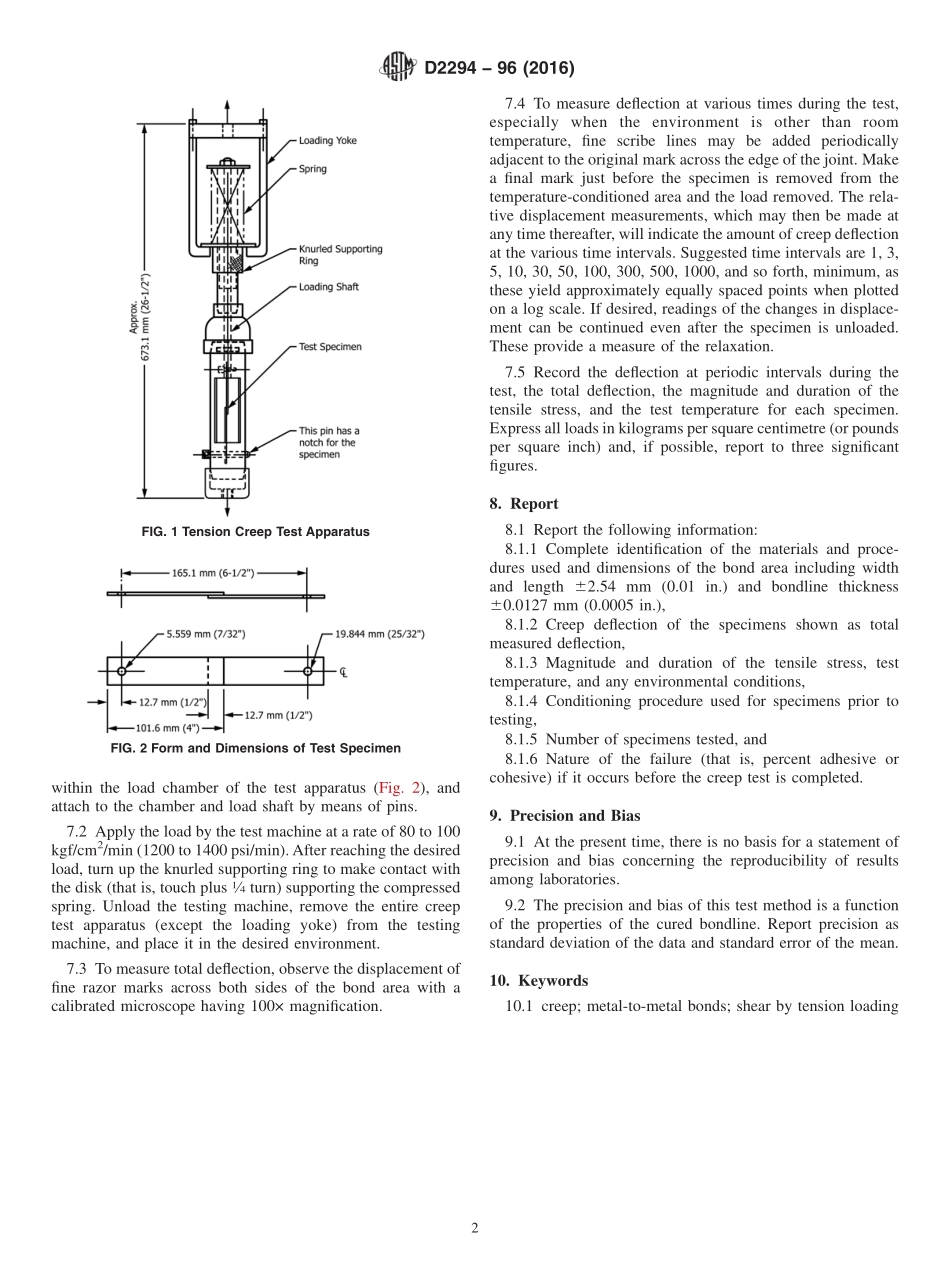

Designation:D2294−96(Reapproved2016)StandardTestMethodforCreepPropertiesofAdhesivesinShearbyTensionLoading(Metal-to-Metal)1ThisstandardisissuedunderthefixeddesignationD2294;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationofthecreeppropertiesofadhesivesforbondingmetalswhentestedonastandardspecimenandsubjectedtocertainconditionsoftemperatureandtensilestressinaspring-loadedtestingappa-ratus.1.2Thistestmethodisapplicabletothetemperaturerangefrom−55to+260°C(−67to+500°F).1.3ThevaluesstatedinSIunitsaretoberegardedasstandard.Thevaluesgiveninparenthesesareforinformationonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D638TestMethodforTensilePropertiesofPlasticsD907TerminologyofAdhesivesD1002TestMethodforApparentShearStrengthofSingle-Lap-JointAdhesivelyBondedMetalSpecimensbyTen-sionLoading(Metal-to-Metal)2.2ASTMAdjuncts:TensionCreepTestApparatus33.Terminology3.1Definitions—ManytermsinthistestmethodaredefinedinTerminologyD907.4.SignificanceandUse4.1Thistestmethodisusefulinresearchanddevelopmentforcomparisonofcreeppropertiesofadhesives,particularlyasthosepropertiesareaffectedbychangesinadhesiveformula-tionorexpectedserviceconditions,includingtemperature,moisturelevel,anddurationofloading.4.2Therelativesizeandsimplicityofdesignofthespring-loadedapparatuspermitseasyportabilityandtransferfromoneenvironmenttothenextwithoutdisturbingstaticloads.4.3Therelativesimplicityofdesignwithinexpensivematerialspermitsreplicationofcreeptestsatrelativelylowcosts.5.Apparatus5.1TensionCreepTestApparatus,as...