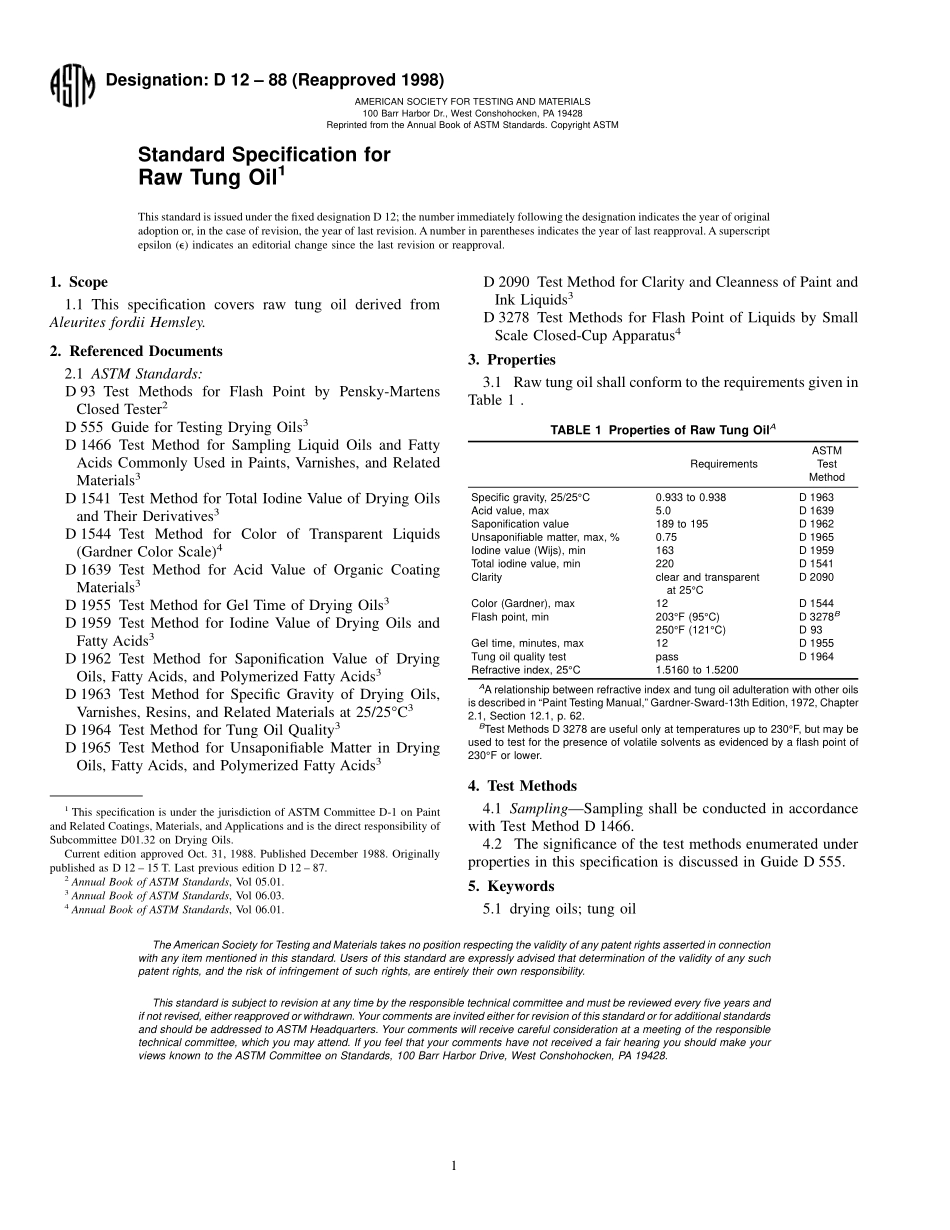

Designation:D12–88(Reapproved1998)StandardSpecificationforRawTungOil1ThisstandardisissuedunderthefixeddesignationD12;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1ThisspecificationcoversrawtungoilderivedfromAleuritesfordiiHemsley.2.ReferencedDocuments2.1ASTMStandards:D93TestMethodsforFlashPointbyPensky-MartensClosedTester2D555GuideforTestingDryingOils3D1466TestMethodforSamplingLiquidOilsandFattyAcidsCommonlyUsedinPaints,Varnishes,andRelatedMaterials3D1541TestMethodforTotalIodineValueofDryingOilsandTheirDerivatives3D1544TestMethodforColorofTransparentLiquids(GardnerColorScale)4D1639TestMethodforAcidValueofOrganicCoatingMaterials3D1955TestMethodforGelTimeofDryingOils3D1959TestMethodforIodineValueofDryingOilsandFattyAcids3D1962TestMethodforSaponificationValueofDryingOils,FattyAcids,andPolymerizedFattyAcids3D1963TestMethodforSpecificGravityofDryingOils,Varnishes,Resins,andRelatedMaterialsat25/25°C3D1964TestMethodforTungOilQuality3D1965TestMethodforUnsaponifiableMatterinDryingOils,FattyAcids,andPolymerizedFattyAcids3D2090TestMethodforClarityandCleannessofPaintandInkLiquids3D3278TestMethodsforFlashPointofLiquidsbySmallScaleClosed-CupApparatus43.Properties3.1RawtungoilshallconformtotherequirementsgiveninTable1.4.TestMethods4.1Sampling—SamplingshallbeconductedinaccordancewithTestMethodD1466.4.2ThesignificanceofthetestmethodsenumeratedunderpropertiesinthisspecificationisdiscussedinGuideD555.5.Keywords5.1dryingoils;tungoilTheAmericanSocietyforTestingandMaterialstakesnopositionrespectingthevalidityofanypatentrightsassertedinconnectionwithanyitemmentionedinthisstandard.Usersofthisstandardareexpresslyadvisedthatdeterminationofthevalidityofanysuchpatentrights,andtheriskofinfringementofsuchrights,areentirelytheirownresponsibility.Thisstandardissubjecttorevisi...