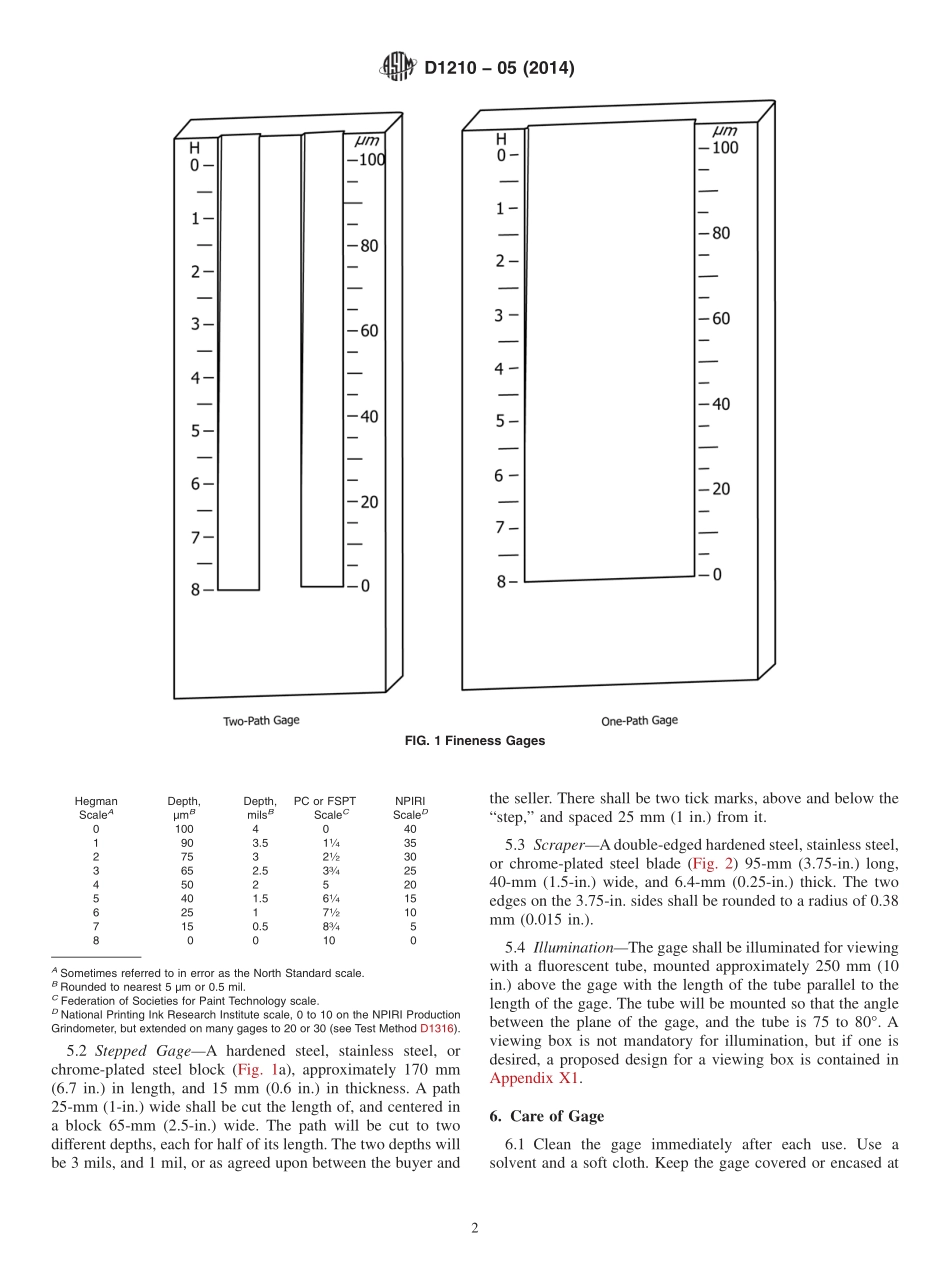

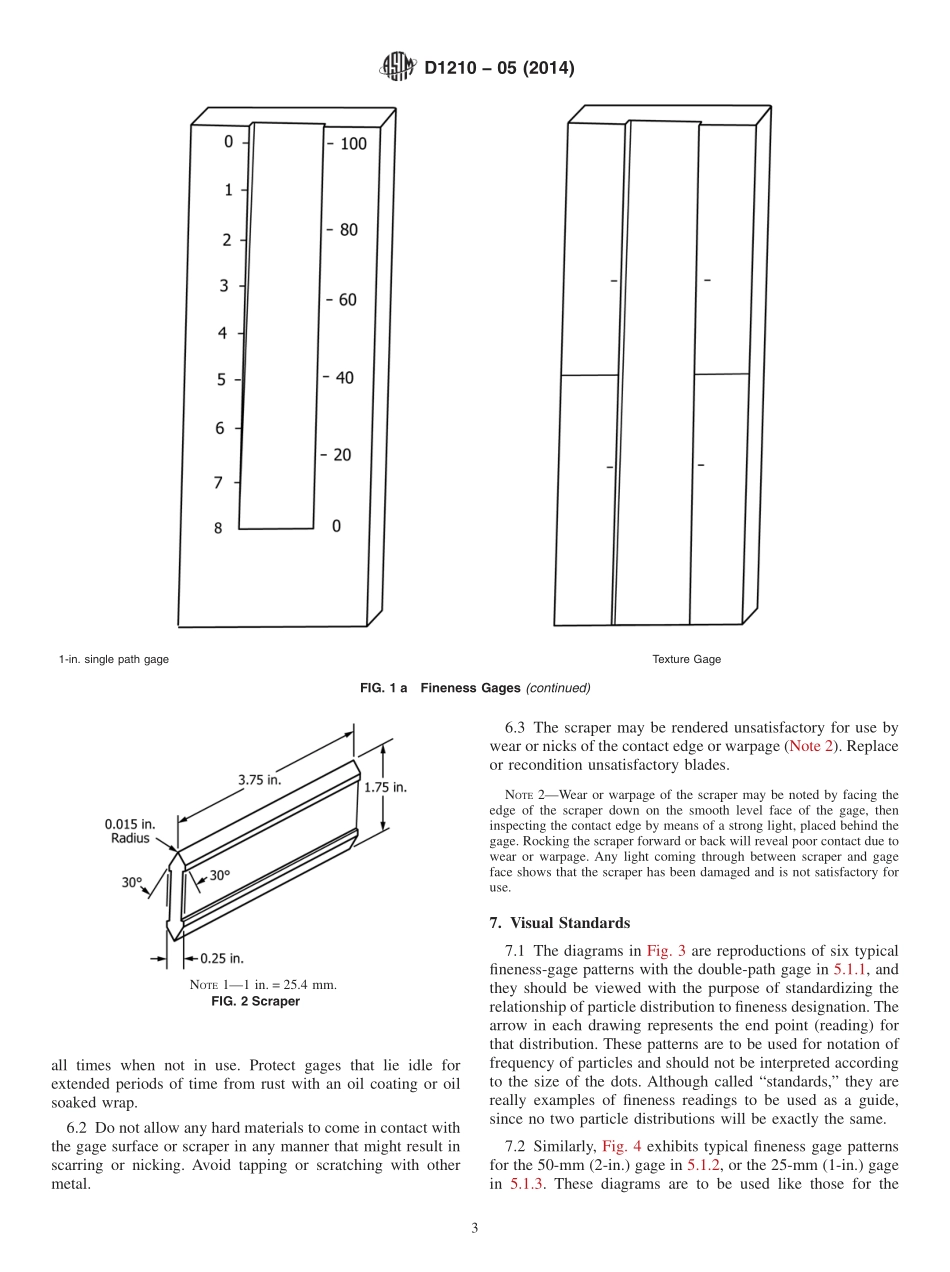

Designation:D1210−05(Reapproved2014)StandardTestMethodforFinenessofDispersionofPigment-VehicleSystemsbyHegman-TypeGage1ThisstandardisissuedunderthefixeddesignationD1210;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thistestmethodcoversmeasurementofthedegreeofdispersion(commonlyreferredtoas“finenessofgrind”)ofthepigmentinapigment-vehiclesystemsuchasliquidcoatingsandtheirintermediates.Itmayalsobeusedtoassesstheinclusionofparticulatesbyacleanliness(ortexture)rating.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D1316TestMethodforFinenessofGrindofPrintingInksBytheNPIRIGrindometer3.SummaryofTestMethod3.1TaperedGage—Theproductisspreadbymeansofascraperinamachinedtaperedpath.Atsomepointinthispath,particlesoragglomerates,orboth,willbecomevisible.Adirectreadingfromthegraduatedscaleisthenmadeatthepointwheretheparticlesformadefinitepattern.Whenthesinglepathgageisuseditisalsopossibletorate“cleanliness”(see6.2).3.2SteppedGage—Theproductisspreadbymeansofascraperonasteppedgage.Thereare2delimitedsectionsonthisgage,eachof6.5cm2(1in.2)area,andoftwodifferentdepths.Acountismadeoftheparticlesdepositedinthetwodelimitedareas,andcleanliness(texture)readingisdeter-mined.4.SignificanceandUse4.1Inmakingpigmentedproducts,thepigmentisusuallydispersedinaportionofthevehicleinsomesortofmill.Atthisstage,itisnecessarytobeabletojudgeifthepigmentagglomerateshavebeensuffici...