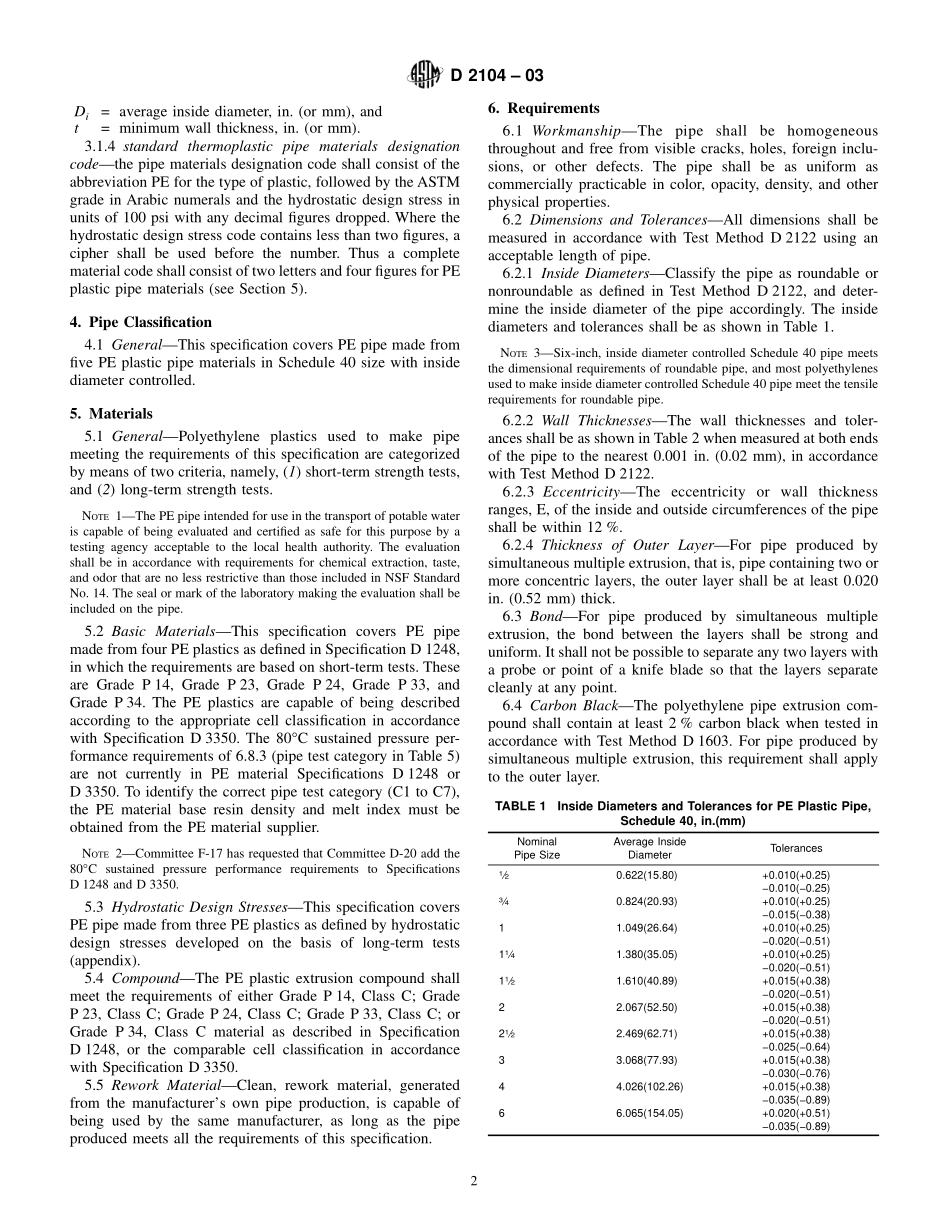

Designation:D2104–03AnAmericanNationalStandardStandardSpecificationforPolyethylene(PE)PlasticPipe,Schedule401ThisstandardisissuedunderthefixeddesignationD2104;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thisspecificationcoverspolyethylene(PE)pipemadeinSchedule40sizeforusewithinsertfittings(insidediametercontrolled)andpressure-ratedforwater(seeAppendix).In-cludedarecriteriaforclassifyingPEplasticpipematerialsandPEplasticpipe,asystemofnomenclatureforPEplasticpipe,andrequirementsandtestmethodsformaterials,workmanship,dimensions,sustainedpressure,burstpressure,andenviron-mentalstresscracking.Requirementsformarkingarealsogiven.1.2Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thefollowingsafetyhazardscaveatpertainsonlytothetestmethodsportion,Section7,ofthisspecification:Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimita-tionspriortouse.2.ReferencedDocuments2.1ASTMStandards:D618PracticeforConditioningPlasticsforTesting2D1238TestMethodforMeltFlowRatesofThermoplasticsbyExtrusionPlastometer2D1248SpecificationforPolyethylenePlasticsExtrusionMaterialsForWireandCable2D1505TestMethodforDensityofPlasticsbytheDensity-GradientTechnique2D1598TestMethodforTime-to-FailureofPlasticPipeUnderConstantInternalPressure3D1599TestMethodforShort-TimeHydraulicFailurePres-sureofPlasticPipe,Tubing,andFittings3D1600TerminologyforAbbreviatedTermsRelatingtoPlastics2D1603TestMethodforCarbonBlackinOlefinPlastics2D2122TestMethodforDeterminingDimensionsofTher-moplasticPipeandFitting...