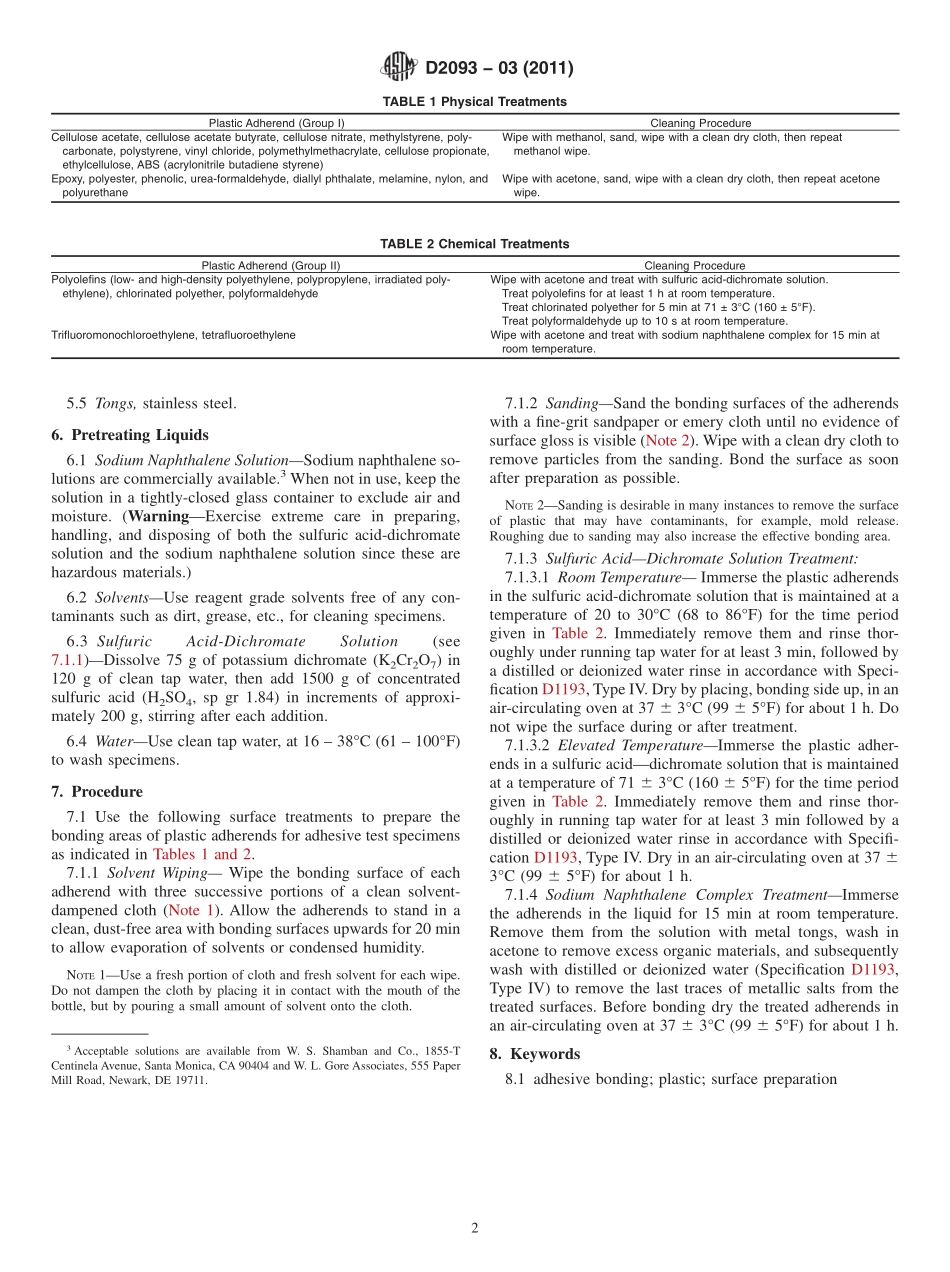

Designation:D2093−03(Reapproved2011)StandardPracticeforPreparationofSurfacesofPlasticsPriortoAdhesiveBonding1ThisstandardisissuedunderthefixeddesignationD2093;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticedescribessurfacepreparationsforplasticadherends,tobeusedpriortoadhesivebondingoftestspecimens.Itshouldbenoted,however,thatthispracticespecifiesonlythepretreatingconditionsoftheplasticanddoesnotcoverthepreparationoftestspecimens,testingconditions,orevaluationoftests.ThesearecoveredinthevariousASTMtestmethodsorspecificationsforspecificmaterials.1.2PhysicalTreatments(forexample,sandingandsolventwiping)areusedinordertoremovetheglossyfinishandalltracesofdirt,grease,moldrelease,orothercontaminantsfromthebondingsurfaces.1.3ChemicalTreatments(forexample,sulfuricacid—dichromatesolutionandsodiumnaphthalenecomplex)areusedinsomecasestoalterchemicallythesurfacelayersofthepolymeritselftoimproveitsadhesioncharacteristics.1.4ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.Specificprecau-tionarystatementsaregivenin6.1.2.ReferencedDocuments2.1ASTMStandards:2D897TestMethodforTensilePropertiesofAdhesiveBondsD903TestMethodforPeelorStrippingStrengthofAdhe-siveBondsD905TestMethodforStrengthPropertiesofAdhesiveBondsinShearbyCompressionLoadingD907TerminologyofAdhesivesD950TestMethodforImpactStrengthofAdhesiveBondsD952TestMethodforBondorCohesiveStrengthofSheetPlasticsandElectricalInsulatingMaterialsD1002TestMethodforApparentShearStrengthofSingle-Lap-JointAdhesivelyBo...