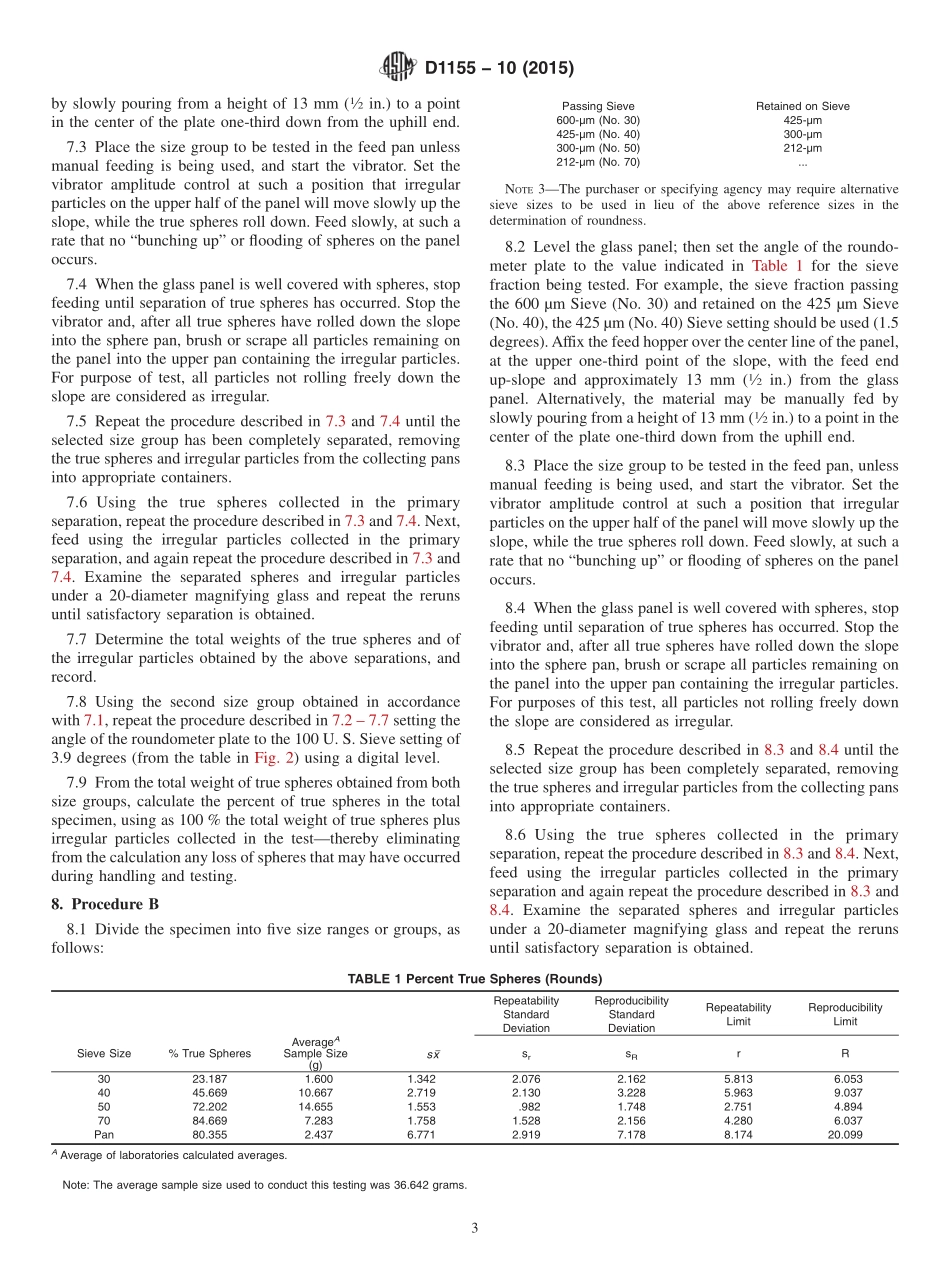

Designation:D1155−10(Reapproved2015)StandardTestMethodforRoundnessofGlassSpheres1ThisstandardisissuedunderthefixeddesignationD1155;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethod2coversthedeterminationofthepercentoftruespheresinglassspheresusedforretroreflectivemarkingpurposesandindustrialuses.1.2Thistestmethodincludestwoproceduresasfollows:1.2.1ProcedureA,inwhichtheselectedspecimenissplitintotwosizerangesorgroupspriortoseparationintotruespheresandirregularparticles,and1.2.2ProcedureB,inwhichtheselectedspecimenissplitintofivesizerangesorgroupspriortoseparation.1.2.3Indeterminingcompliancewithspecificationrequirements,eitherProcedureAorProcedureBmaybeused.Wheretestsindicatefailuretomeetthespecifiedpercentoftruespheresandirregularparticles,therefereetestshallbemadeinaccordancewithProcedureB.1.3ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:3E11SpecificationforWovenWireTestSieveClothandTestSievesE177PracticeforUseoftheTermsPrecisionandBiasinASTMTestMethodsE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod2.2OtherDocument:ASTMMNL32ManualonTestSievingMethods3.SummaryofTestMethod3.1Theglassparticlesaremechanicallyseparatedintotruespheresandirregularparticlesbycontrolledvibrationonaglassplatefixedatapredeterminedslope.4.SignificanceandUse4.1Theroundnessofglassspheresisonemeasurableaspectrelatingtotheirperformanceasaretroreflectivemedia.Thefunctionofthistestmethodistomeasurethepe...