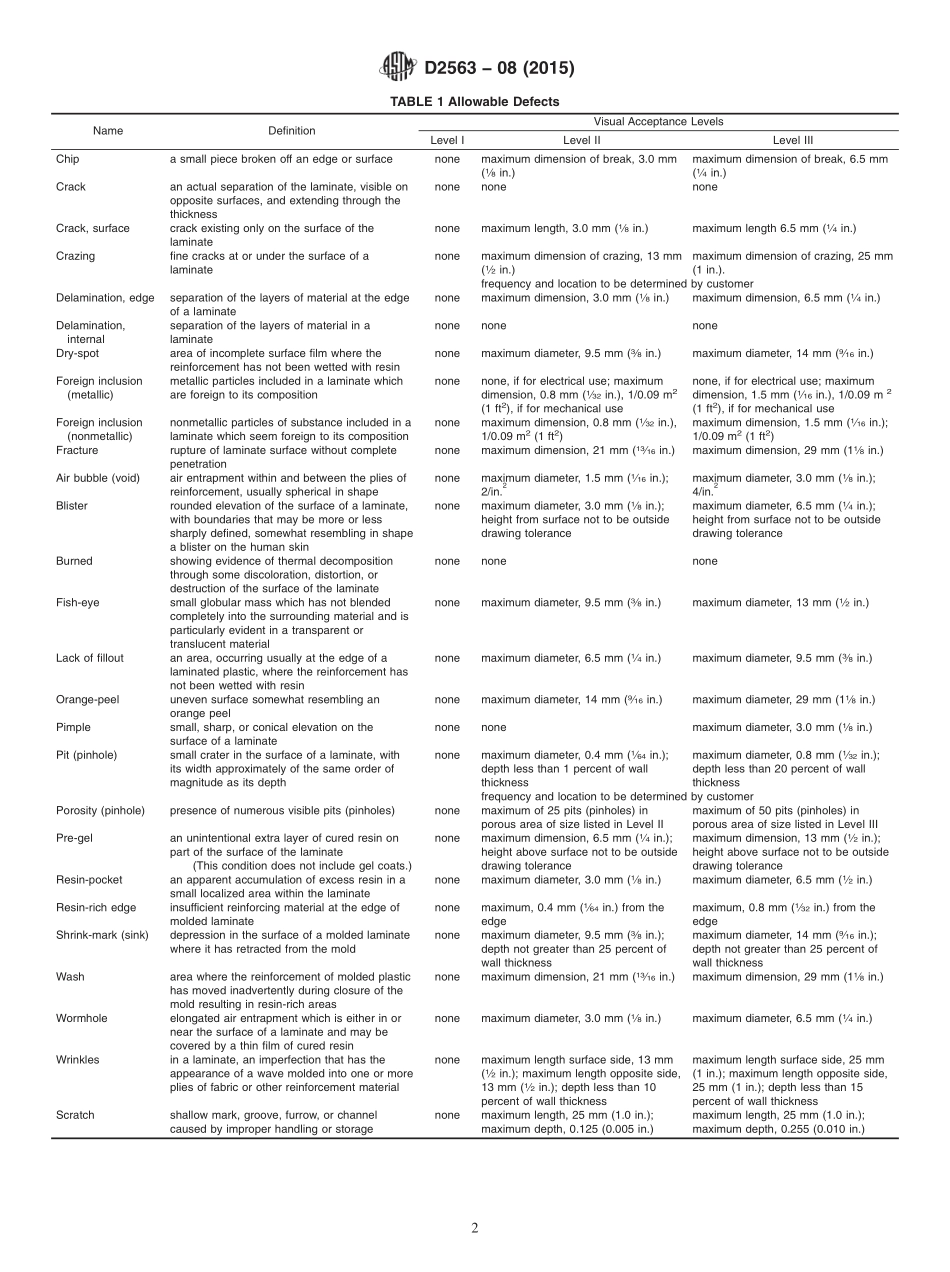

Designation:D2563−08(Reapproved2015)StandardPracticeforClassifyingVisualDefectsinGlass-ReinforcedPlasticLaminateParts1ThisstandardisissuedunderthefixeddesignationD2563;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thispracticecoversacceptancecriteriaforvisualin-spectionofpartsmadefrommoldedglass-reinforcedplasticlaminates.1.2Thispracticepresentsworddescriptionsofpossibledefectstoserveasaguideforcontracts,drawings,productspecifications,andfinalinspection.1.3Thispracticealsocategorizesdifferentinspectionre-quirementsforlevelsofproductquality.1.4Theallowablesizeandfrequencyofpermitteddefectswithintheacceptancelevelcategoriesofthisspecificationaregeneralandnotrelatedtospecificservicerequirements.ALevelIVofallowabledefectswhichdefinesallowablesize,frequency,andpermittedrepairproceduresshouldbeestab-lishedforspecificservicerequirementsasagreeduponbe-tweenthepurchaserandthesupplier.1.5ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.6Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.NOTE1—ThereisnoknownISOequivalenttothisstandard.2.AcceptanceCriteria2.1Themethodandfrequencyofsamplingandtheallow-abledefectsmaybepreviouslyagreeduponbetweenthepurchaserandtheseller.2.2DimensionsandTolerances—Partsshallbeinspectedforconformancewithdimensionsandtolerancesspecifiedonthedrawings.Anydimensionsfallingoutsidethespecifiedlimitsshallbecauseforrejection.2.3Inserts—Allinserts,nuts,studs,andlugsshallnotbedamagedinanyway,norcoatedwithlaminatematerialsinsuc...