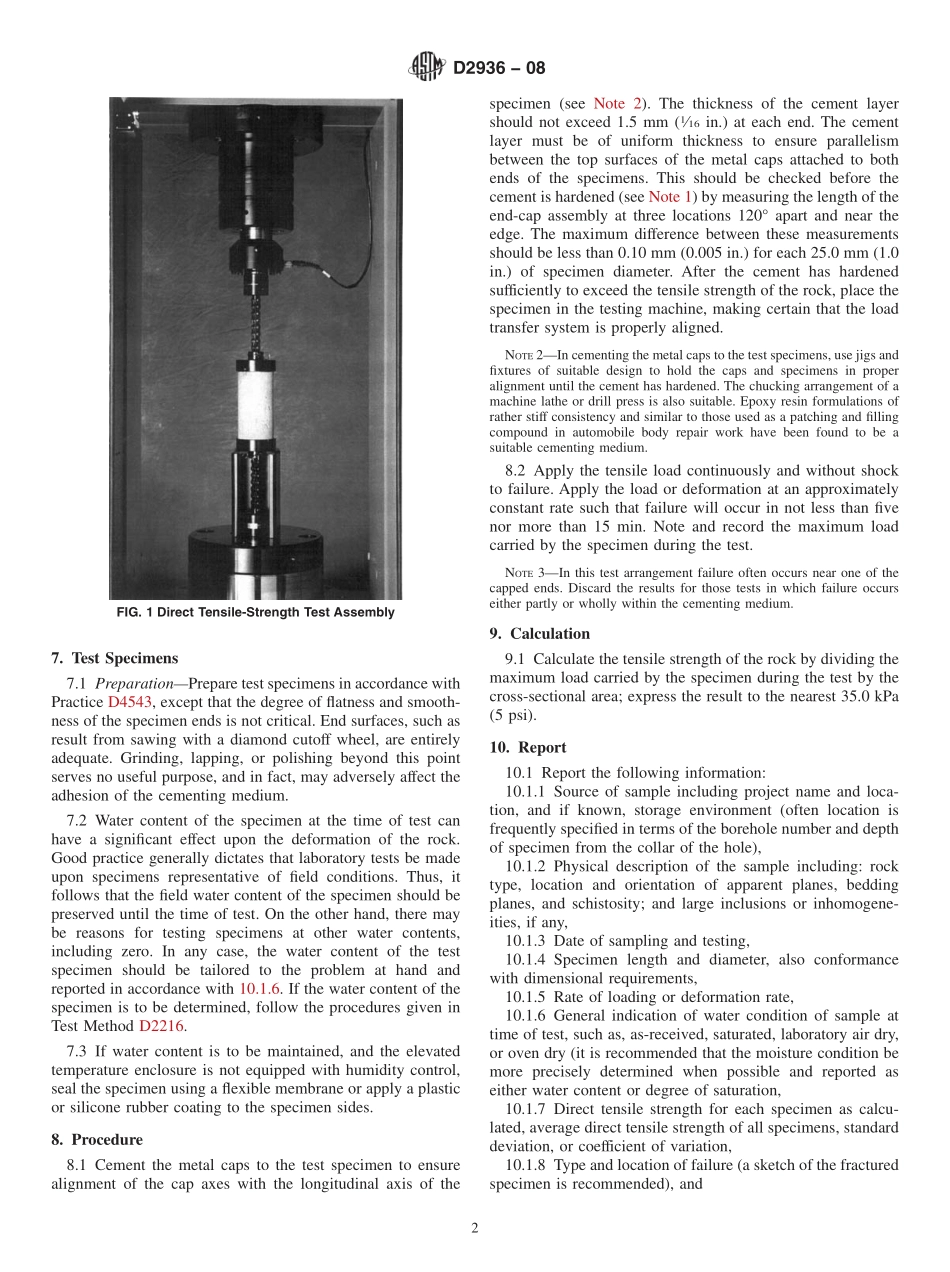

Designation:D2936−08StandardTestMethodforDirectTensileStrengthofIntactRockCoreSpecimens1ThisstandardisissuedunderthefixeddesignationD2936;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thistestmethodcoversthedeterminationofthedirecttensilestrengthofintactcylindricalrockspecimens.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Thevaluesprovidedinparenthesisareforinforma-tiononly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D2216TestMethodsforLaboratoryDeterminationofWater(Moisture)ContentofSoilandRockbyMassD3740PracticeforMinimumRequirementsforAgenciesEngagedinTestingand/orInspectionofSoilandRockasUsedinEngineeringDesignandConstructionD4543PracticesforPreparingRockCoreasCylindricalTestSpecimensandVerifyingConformancetoDimensionalandShapeTolerancesE4PracticesforForceVerificationofTestingMachinesE122PracticeforCalculatingSampleSizetoEstimate,WithSpecifiedPrecision,theAverageforaCharacteristicofaLotorProcess3.SummaryofTestMethod3.1Arockcoresampleiscuttolengthanditsendsarecementedtometalcaps.Themetalcapsareattachedtoatestingmachineandthespecimenisloadedintensionuntilitfails.4.SignificanceandUse4.1Rockismuchweakerintensionthanincompression.Thus,indeterminingthefailureconditionforarockstructure,manyinvestigatorsemploytensilestrengthofthecomponentrockasthefailurestrengthforthestructure.Directtensilestressingofrockisthemostbasictestfordeterminingthetensilestrengthofrock.5.Apparatus5.1LoadingDevice,toapplyandmeasureaxialloadonthespecimen,ofsufficientcapacitytoapplytheloadatarateconformingtotherequirementsof8.2.Thedevic...