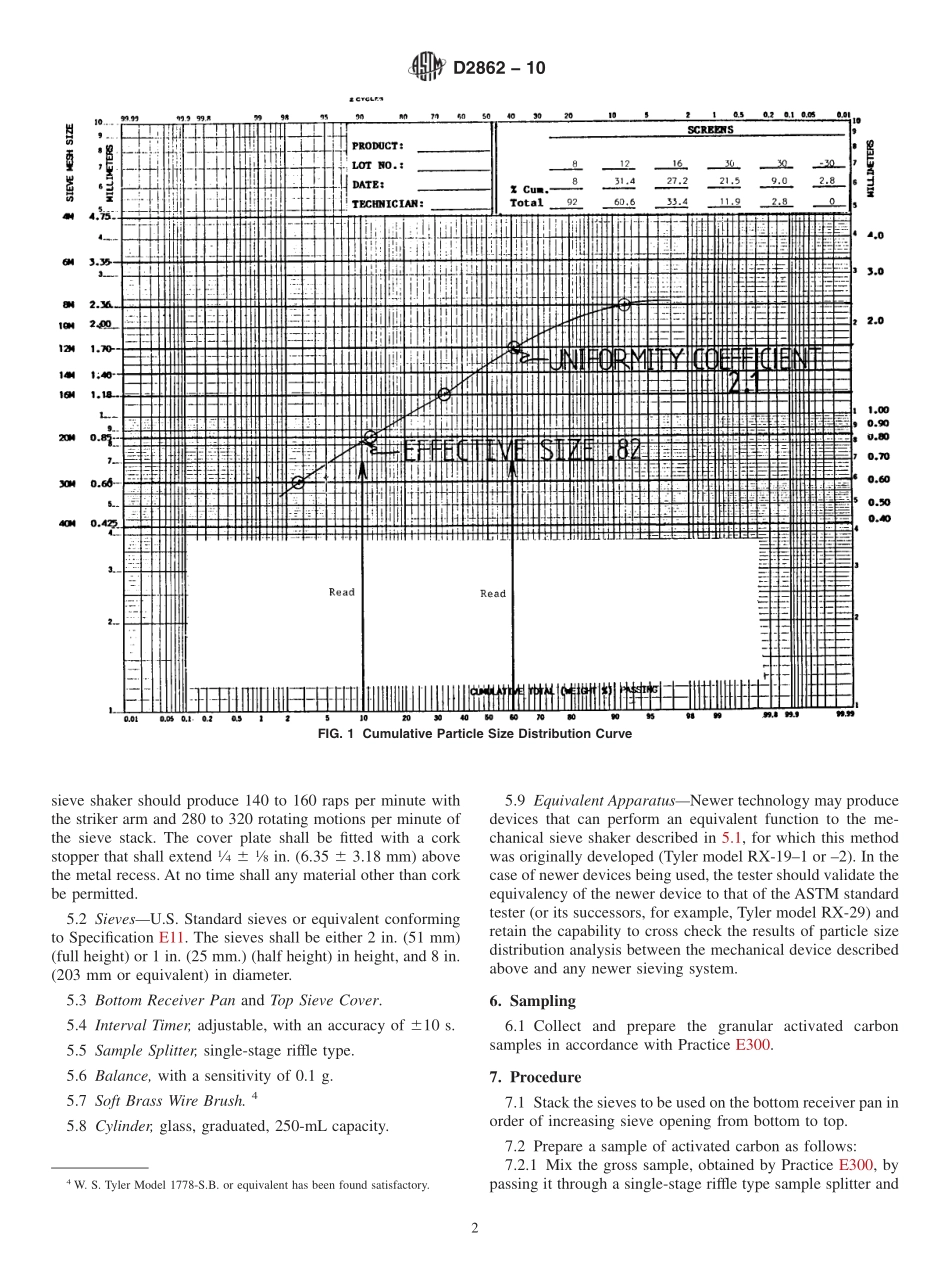

Designation:D2862−10StandardTestMethodforParticleSizeDistributionofGranularActivatedCarbon1ThisstandardisissuedunderthefixeddesignationD2862;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thistestmethodcoversthedeterminationoftheparticlesizedistributionofgranularactivatedcarbon.Forthepurposesofthistest,granularactivatedcarbonisdefinedasaminimumof90%ofthesampleweightbeingretainedona180-µmStandardsieve.AU.S.mesh80sieveisequivalenttoa180–µmStandardsieve.NOTE1—Forextrudedcarbons,asthelength/diameterratiooftheparticlesincreases,thevalidityofthetestresultsmightbeaffected.1.2Thedataobtainedmayalsobeusedtocalculatemeanparticlediameter(MPD),effectivesize,anduniformitycoef-ficient.1.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3.1Exception—AllmassmeasurementsareinSIunitsonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D2652TerminologyRelatingtoActivatedCarbonD2854TestMethodforApparentDensityofActivatedCarbonE11SpecificationforWovenWireTestSieveClothandTestSievesE177PracticeforUseoftheTermsPrecisionandBiasinASTMTestMethodsE300PracticeforSamplingIndustrialChemicalsE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.SummaryofTestMethod3.1AknownweightofgranularactivatedcarbonisplacedonthetopsieveofastackedsetofU.S.Standardsievesandshakenunderstandardconditionsforaspecifictimeperiod,after...