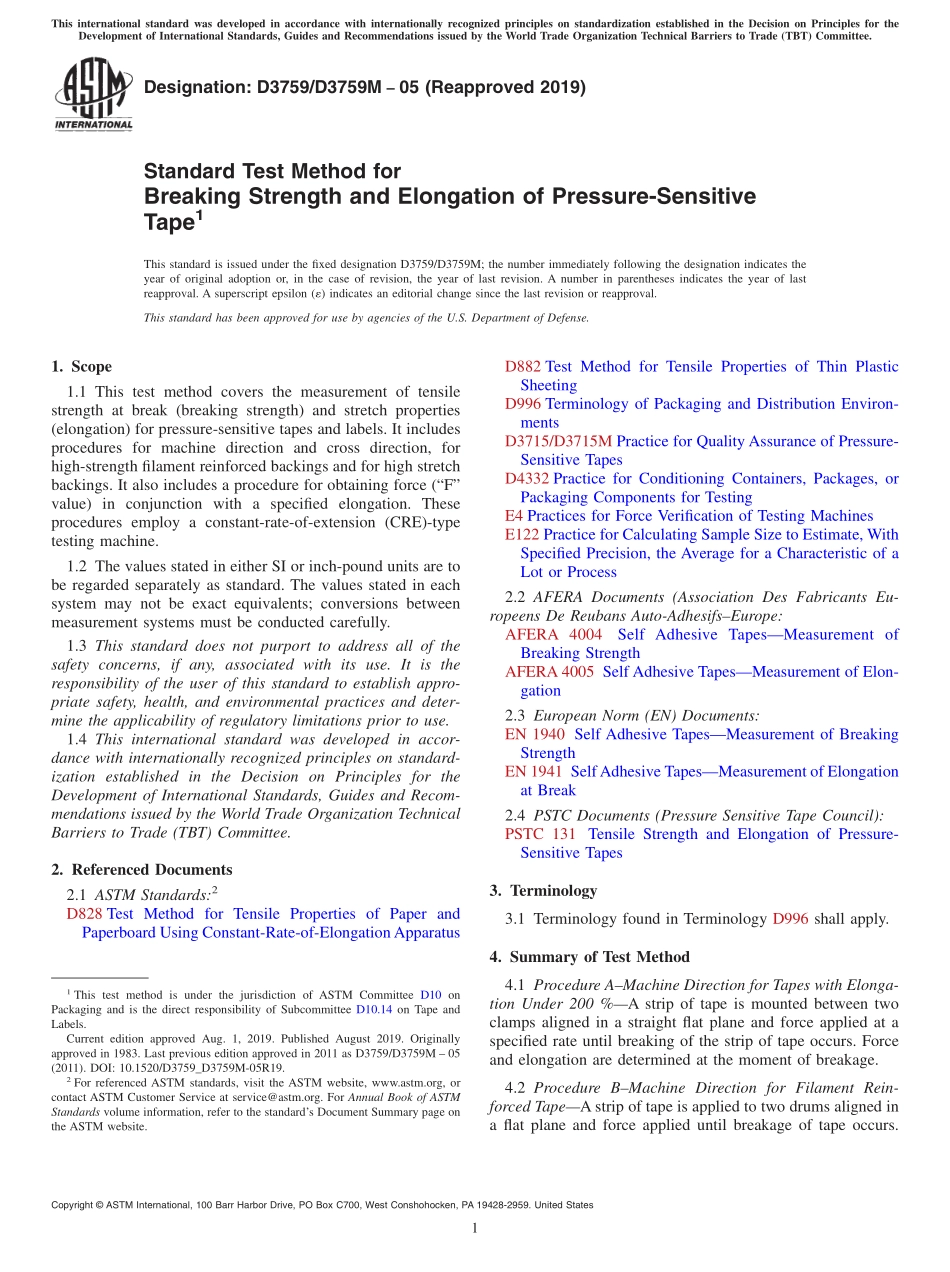

Designation:D3759/D3759M−05(Reapproved2019)StandardTestMethodforBreakingStrengthandElongationofPressure-SensitiveTape1ThisstandardisissuedunderthefixeddesignationD3759/D3759M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thistestmethodcoversthemeasurementoftensilestrengthatbreak(breakingstrength)andstretchproperties(elongation)forpressure-sensitivetapesandlabels.Itincludesproceduresformachinedirectionandcrossdirection,forhigh-strengthfilamentreinforcedbackingsandforhighstretchbackings.Italsoincludesaprocedureforobtainingforce(“F”value)inconjunctionwithaspecifiedelongation.Theseproceduresemployaconstant-rate-of-extension(CRE)-typetestingmachine.1.2ThevaluesstatedineitherSIorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;conversionsbetweenmeasurementsystemsmustbeconductedcarefully.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D828TestMethodforTensilePropertiesofPaperandPaperboardUsingConstant-Rate-of-ElongationApparatusD882TestMethodforTensilePropertiesofThinPlasticSheetingD996TerminologyofPackagingandDistributionEnviron-mentsD3715/D3715MPracticeforQualityAssuranceofPressure-SensitiveTapesD4332P...