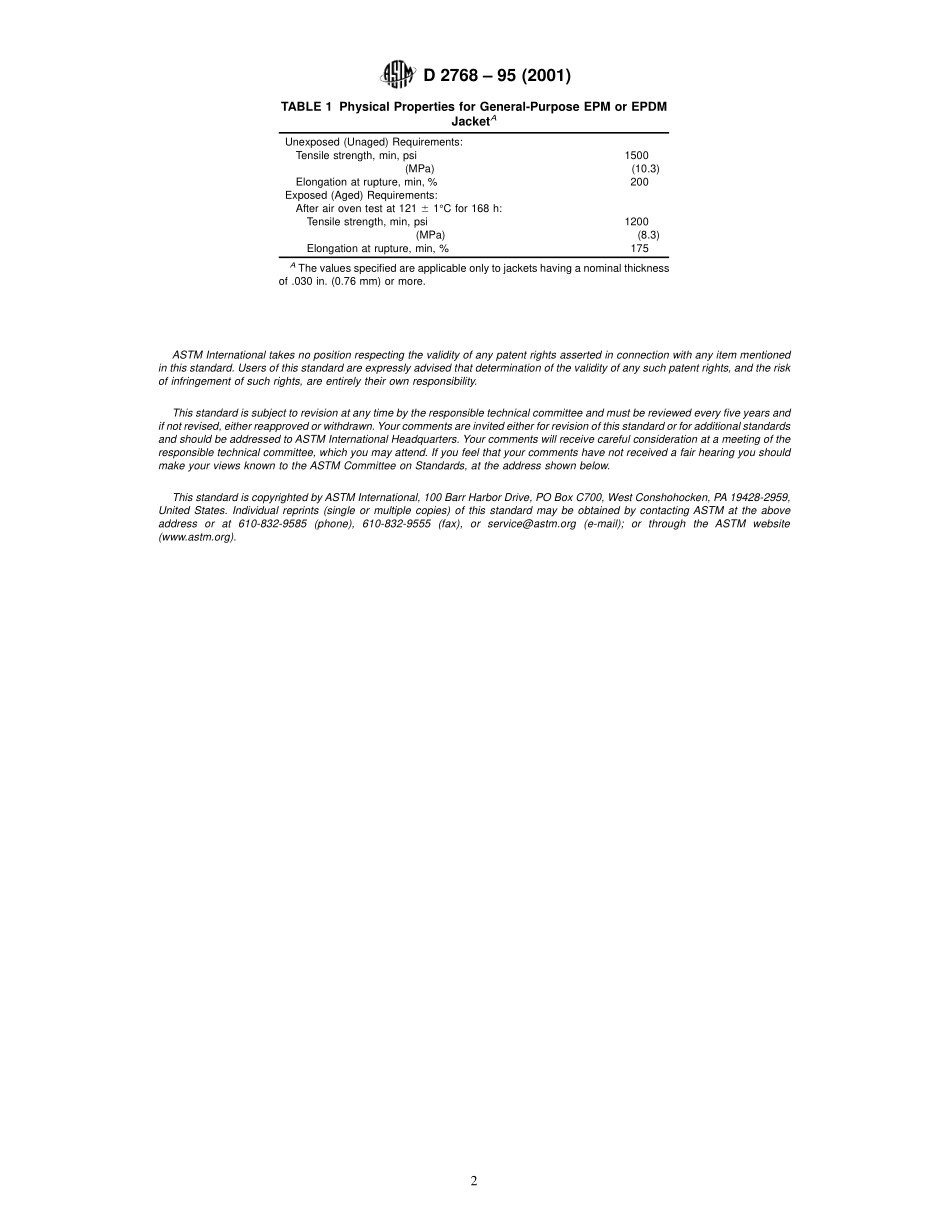

Designation:D2768–95(Reapproved2001)AnAmericanNationalStandardStandardSpecificationforGeneral-PurposeEthylene-PropyleneRubberJacketforWireandCable1ThisstandardisissuedunderthefixeddesignationD2768;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversaweatherandozone-resistingcrosslinkedcompoundforuseastheoutercoveringorjacketoninsulatedwiresandcables.Thepolymercomponentofthismaterialconsistssubstantiallyofethylenepropylenecopolymer(EPM)orethylene-propyleneterpolymer(EPDM).1.2Thevaluesstatedininch-poundunitsarethestandard,exceptincaseswhereSIunitsaremoreappropriate.Thevaluesinparenthesesareforinformationonly.2.ReferencedDocuments2.1ASTMStandards:D257TestMethodsforDCResistanceorConductanceofInsulatingMaterials2D470TestMethodsforCrosslinkedInsulationsandJacketsforWireandCable2D1499PracticeforFilteredOpen-FlameCarbon-ArcEx-posuresofPlastics3G23PracticeforOperatingLight-ExposureApparatus(Carbon-ArcType)WithandWithoutWaterforExposureofNonmetallicMaterials43.ElectricalRequirements3.1Whenusedonsingleconductornonshieldedcablesrated2001through5000Vphasetophase,thejacketshallmeetthefollowingrequirementsofTestMethodsD470:3.1.1SurfaceResistivity—Thejacketshallhaveasurfaceresistivityequaltoorgreaterthan200000MV.3.1.2U-BendDischarge—ThereshallbenocablefailurenorcracksinthejacketwhenasampleofcompletedcableissubjectedtotheU-benddischargetestat150V/mil(6kV/mm)foratleast6h.4.TestApplicableforSunlightandWeatherResistantMaterials4.1Thejacketshallretainaminimumof80%ofitsunagedtensilestrengthandelongationafter720hofexposureinadualcarbon-arcapparatus.PreparethespecimensinaccordancewithTestMethodsD470forphysicaltestsofinsulationsandjackets.PerformthetestinaccordancewithPracticeD1499usingMethod1ofPracticeG23.5.PhysicalRequirements5.1Thecrosslinkedjackets...