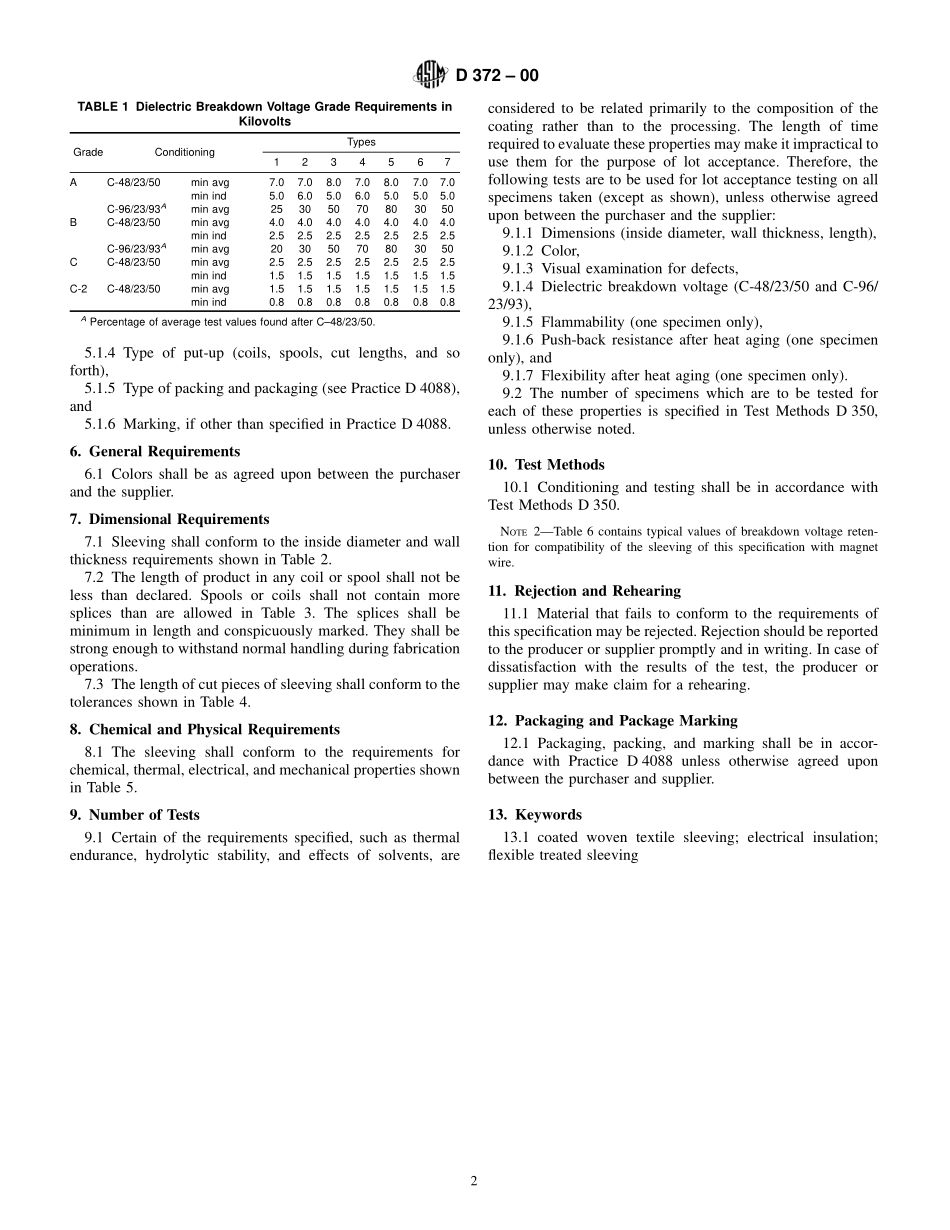

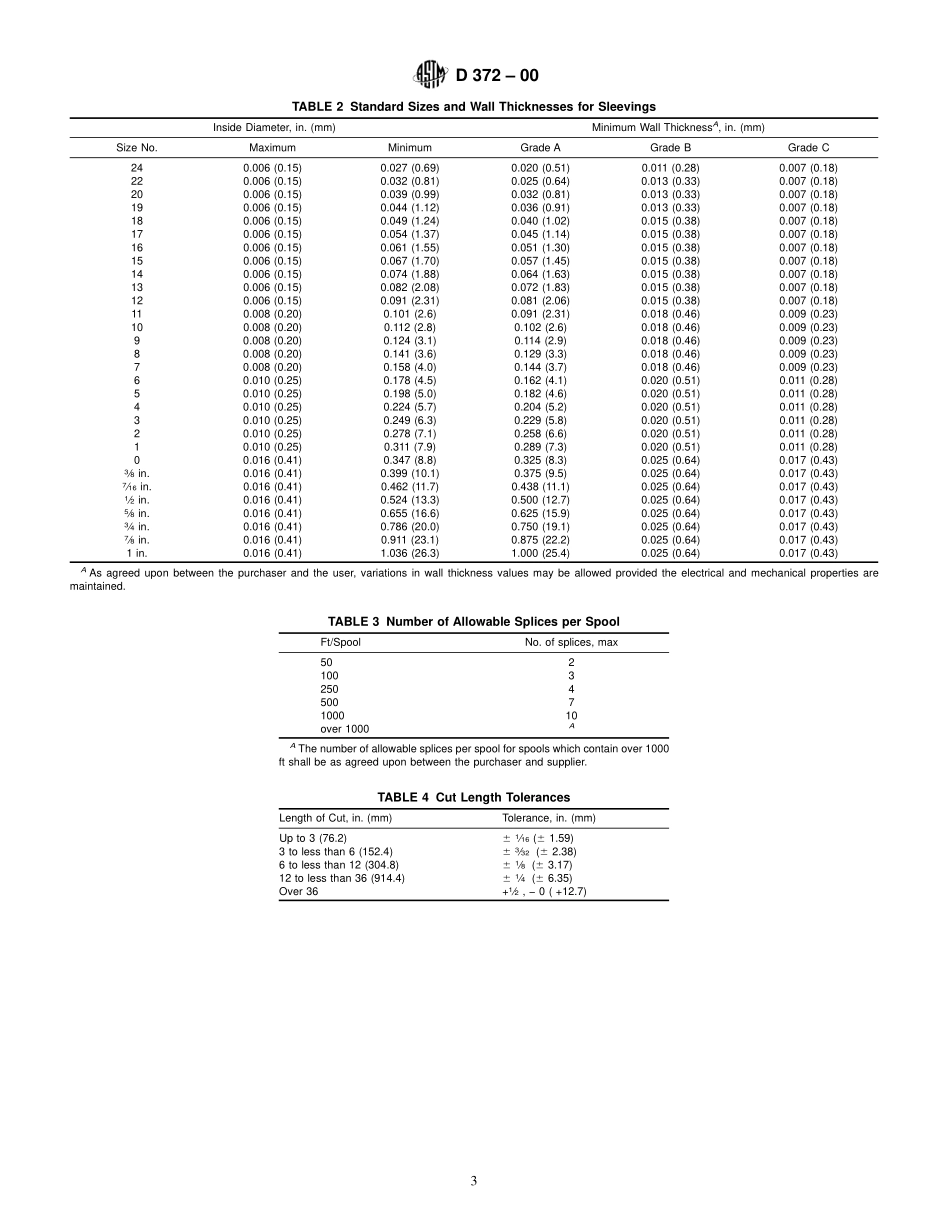

Designation:D372–00AnAmericanNationalStandardStandardSpecificationforFlexibleTreatedSleevingUsedforElectricalInsulation1ThisstandardisissuedunderthefixeddesignationD372;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoverselectricalinsulatingsleevingsuitableforuseonleadwiresandinconnectionsinelectricalapparatus,suchasmotors,transformers,andswitchgears.1.2Materialsunderthisspecificationarelimitedtoaflex-ibletubularproductmadefromawoventextilefiberbase,suchascotton,rayon,nylon,orglass,thereafterimpregnated,orcoated,orimpregnatedandcoated,withasuitableinsulatingmaterial.NOTE1—ThisstandardresemblesIEC60684-3-400to408intitleonly.Thecontentissignificantlydifferent.2.ReferencedDocuments2.1ASTMStandards:D350TestMethodsforFlexibleTreatedSleevingUsedforElectricalInsulation2D1711TerminologyRelatingtoElectricalInsulation2D3636PracticeforSamplingandJudgingQualityofSolidElectricalInsulatingMaterials3D4088PracticeforPreparationforShipmentofSolidElectricalInsulatingMaterials32.2IECStandard:IEC60684-3SpecificationforFlexibleInsulatingSleeving43.Terminology3.1Definitions—Fordefinitionsoftermsusedinthisspeci-fication,seeTerminologyD1711.4.Classification4.1Sleevingiscategorizedbythetypeofcoating,basefabricmaterial,dielectricbreakdownvoltage,temperatureindex,minimumwallthickness,andinsidediameter,asfol-lows:4.1.1TypeI—Aflexibletreatedsleevingmadefromorganic-basefiberssuchascotton,rayon,ornylonandimpreg-natedorcoatedwithaninsulatingmaterialwhichcanbeshownbyapplicableexperienceoracceptedtesttohaveatemperatureindexof105.4.1.2TypeII—Aflexibletreatedsleevingmadefrominorganic-baseyarnssuchasfibrousglassandimpregnatedorcoatedwithaninsulatingmaterialwhichcanbeshownbyapplicableexperienceoracceptedtesttohaveatemperatureindexof130.4.1.3TypeIII—Aflexibletrea...