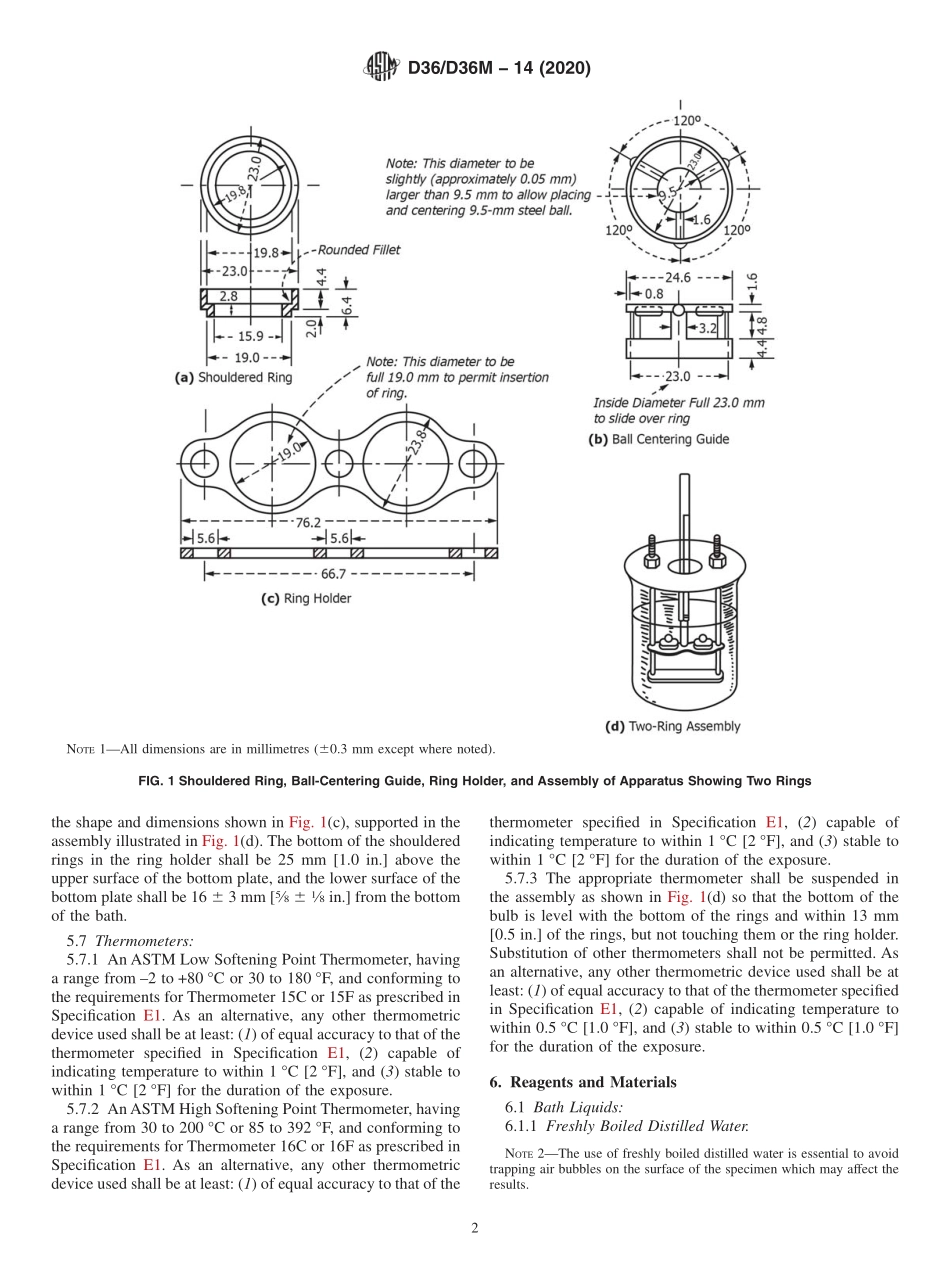

Designation:D36/D36M−14(Reapproved2020)StandardTestMethodforSofteningPointofBitumen(Ring-and-BallApparatus)1ThisstandardisissuedunderthefixeddesignationD36/D36M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationofthesoft-eningpointofbitumenintherangefrom30to157°C[86to315°F]usingthering-and-ballapparatusimmersedindistilledwater[30to80°C]orUSPglycerin(above80to157°C).1.2ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnonconformancewiththestandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2C670PracticeforPreparingPrecisionandBiasStatementsforTestMethodsforConstructionMaterialsD92TestMethodforFlashandFirePointsbyClevelandOpenCupTesterD140/D140MPracticeforSamplingAsphaltMaterialsD3461TestMethodforSofteningPointofAsphaltandPitch(MettlerCup-and-BallMethod)E1SpecificationforASTMLiquid-in-GlassThermometersE177PracticeforUseoftheTermsPrecisionandBiasinASTMTestMethodsE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.SummaryofTestMethod3.1Twohorizontaldisksofbitumen,castinshould...