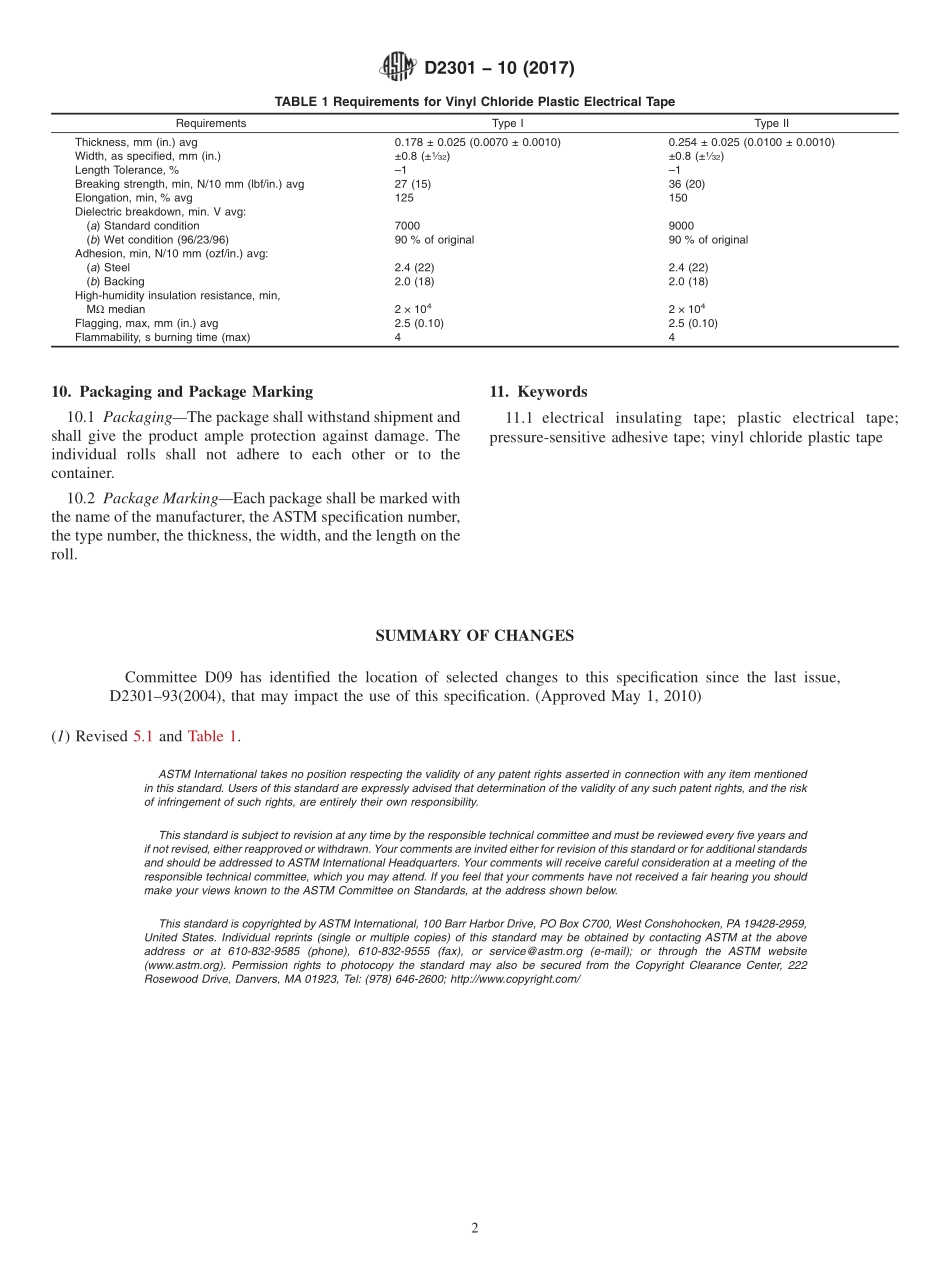

Designation:D2301−10(Reapproved2017)StandardSpecificationforVinylChloridePlasticPressure-SensitiveElectricalInsulatingTape1ThisstandardisissuedunderthefixeddesignationD2301;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationcoverselectricalinsulatingtapecon-sistingofaflexiblebackingmadefromvinylchlorideplasticcoatedononesidewithapressure-sensitiveadhesive.1.2ThevaluesstatedinSIunitsarethestandard.Thevaluesgiveninparenthesesareprovidedforinformationpurposesonly.2.ReferencedDocuments2.1ASTMStandards:2D1000TestMethodsforPressure-SensitiveAdhesive-CoatedTapesUsedforElectricalandElectronicApplica-tionsD1711TerminologyRelatingtoElectricalInsulation3.Terminology3.1Definitions—Fordefinitionsoftermsinthisspecification,refertoTerminologyD1711.4.Classification4.1Thisspecificationcoverstwotypesasfollows:4.1.1TypeI—General-purposetape,nominalthickness0.18mm(0.007in.).4.1.2TypeII—General-purposetape,nominalthickness0.25mm(0.010in.).5.MaterialsandManufacture5.1Thebackingshallbepolyvinylchlorideplasticsuitablycompoundedtomeettherequirementsofthisspecification.Thebackingshallbesmoothanduniform.Thetapeedgesshallbestraightandunbroken.5.2Thepressure-sensitiveadhesivecoatingshallbesmoothanduniformandasfreefromlumpsandbarespotsasthebestcommercialpracticewillpermit.Thereshallbenoadhesivetransferwhenthetapeisunwoundfromtheroll.5.3Blackplasticbackingshallbeconsideredstandard.Othercolors,opaqueortransparent,areacceptablewhenspecified.6.Requirements6.1ThetapeshallmeettherequirementsgiveninTable1forthetypespecified.7.StandardRolls7.1Thestandardwidthsandlengthsshallbeselectedfromthefollowing:7.1.1Widths:mmin.mmin.61⁄4227⁄893⁄8251121⁄23011⁄4155⁄83811⁄2193⁄45027.1.1.1Widthsgreaterthan50mm(2in.)shallbeagreeduponbetweenthepurchaserandtheseller.7.1.2Lengt...