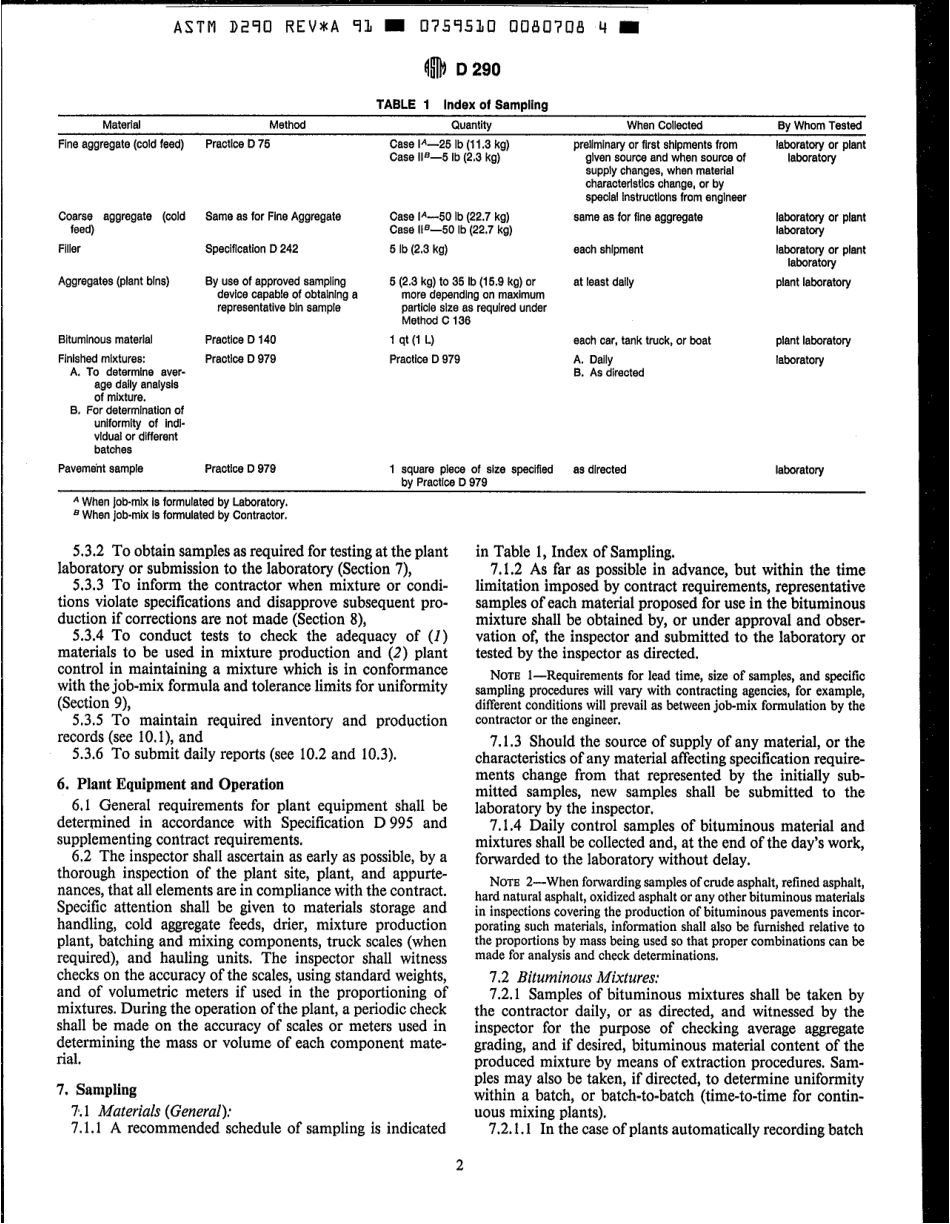

ASTMD290REV*A91m0759530008070724[TbDesignation:D290-91aAMERICANSOCIETYFORTESTINGANDMATERIALS1916RaceStPhiladelphia,Pa19103ReprintedfromtheAnnualBookofASTMStandards.CopyrightASTMIfnotlistedinthecurrentcombinedindex,willappearinthenexiedition.StandardPracticeforBituminousMixingPlantInspection’ThisstandardisissuedunderthefixeddesignationD290;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticedefinestheauthorityanddutiesoftheinspectoratthebituminousmixingplant.Thesedutiesareperformedinordertoensurethecontractor’scompliancewiththecontractandapplicablespecificationsanddonotinanywayrelievethecontractoroftheresponsibilitytoproduceuniformmixturesincompliancewiththecontract.1.2Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyproblems,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatory/imitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:C136MethodforSieveAnalysisofFineandCoarseD75PracticeforSamplingAggregates)D140PracticeforSamplingBituminousMaterials3D242SpecificationforMineralFillerforBituminousD546TestMethodforSieveAnalysisofMineralFillerforD979PracticeforSamplingBituminousPavingMixtures3D995SpecificationforMixingPlantsforHot-Mixed,Hot-LaidBituminousPavingMixtures3D3666PracticeforEvaluatingand.QualifyingAgenciesTestingandInspectingBituminousPavingMaterial9Aggregates2s3PavingMixtures3RoadandPavingMaterials33.Terminology3.1DescriptionsofTermsSpecifictoThisStandard:3.1.1engineer,n-thepartyinresponsiblechargeoftheworkortheengineer’sdulyrecognizedorauthorizedrepre-sentative.3.1.2inspector,n-theengineer’s(orintheabsenceoftheengineer,thepurchaser’s)authorizedrepresentativede...