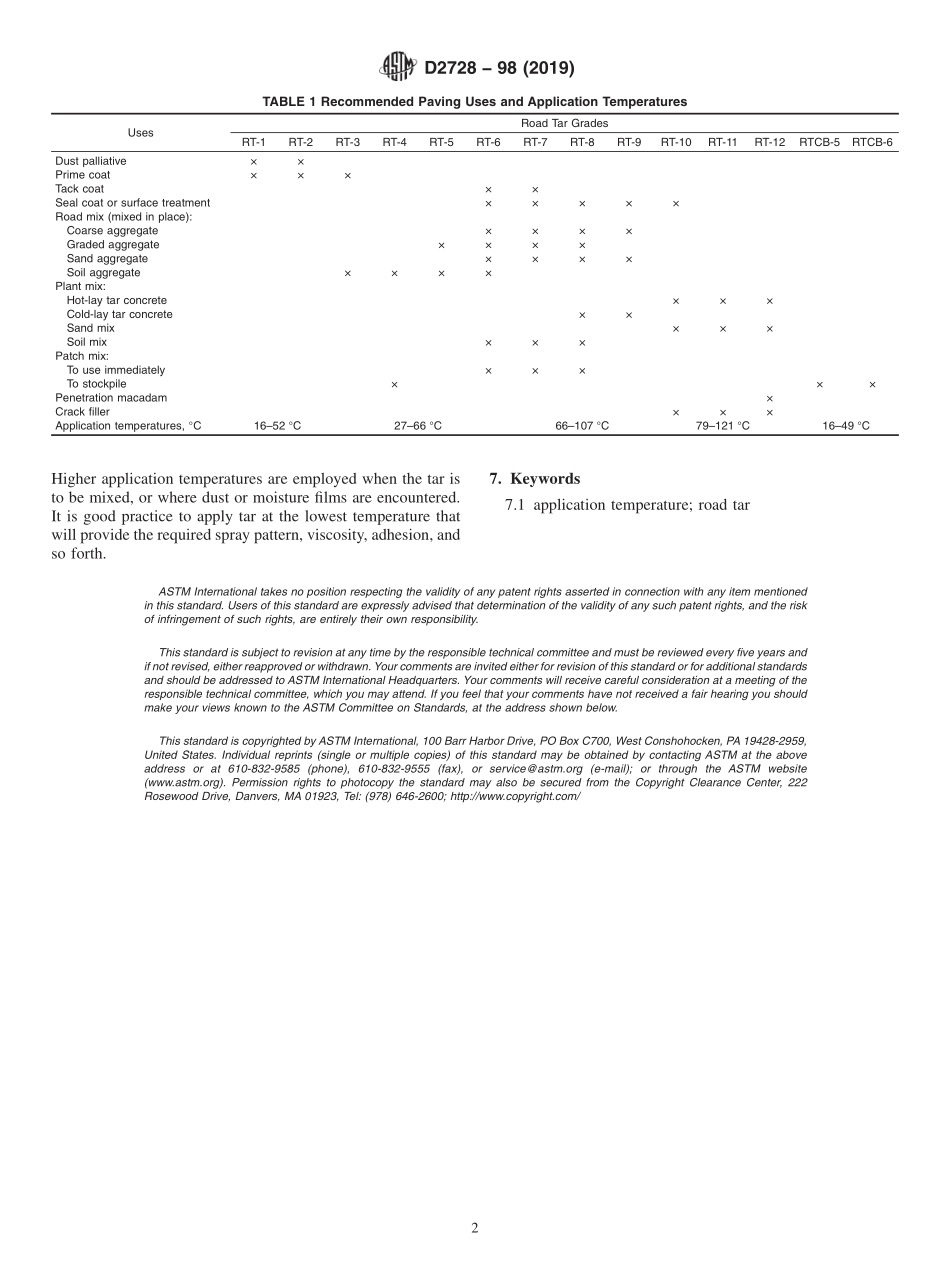

Designation:D2728−98(Reapproved2019)StandardPracticeforPavingUsesandApplicationTemperaturesforRoadTars1ThisstandardisissuedunderthefixeddesignationD2728;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticecoverstheselectionandapplicationtem-peraturesofroadtargradesintheconstructionandmainte-nanceofpavements.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.3Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D8TerminologyRelatingtoMaterialsforRoadsandPave-ments3.Terminology3.1Definitions:ThedefinitionsoftermsnotincludedinTerminologyD8arelistedbelow.3.1.1dustpalliative—alightapplicationofalow-viscositybituminousmaterialfortheexpresspurposeoflayingandbondingdustorpreventingadustnuisance.3.1.2plantmix—amixtureofbituminousmaterialandmineralaggregatepreparedinacentralbituminousmixingplant,thenspreadandcompactedatthejobsite.Plantmixesinclude:3.1.2.1cold-laytarconcrete—aplantmixcontainingamedium-viscositygradeoftarandalessdenselygradedaggregatedesignedtobelaideithershortlyaftermixingorwhenthemixtureisatornearambienttemperature.3.1.2.2hot-laytarconcrete—aplantmixcontainingahigh-viscositygradeoftarandadenselygradedmineralaggregate,designedtobelaidatorneartheelevatedtemperatureofmixing.3.1.2.3sandmix—aplantmixcontainingsandaggregateandahigh-viscositygradeoftardesignedtobelaidimmedi-ately.3.1.2.4soilmix—aplantmixcontainingsoilaggregateandalow-to-mediumviscositygradeofbituminousmaterial,usuallydesignedtobestockpiled,thenlaidfo...