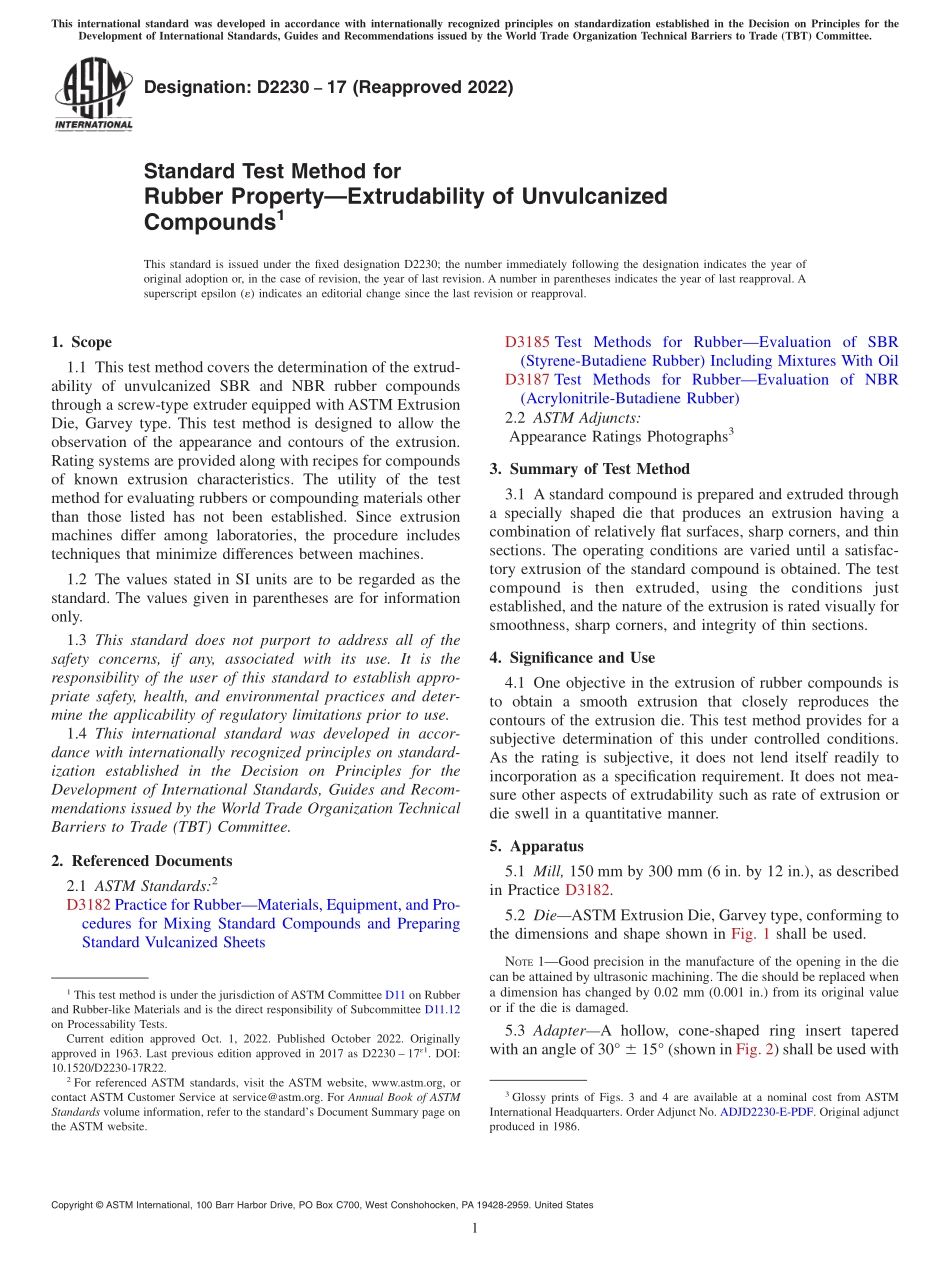

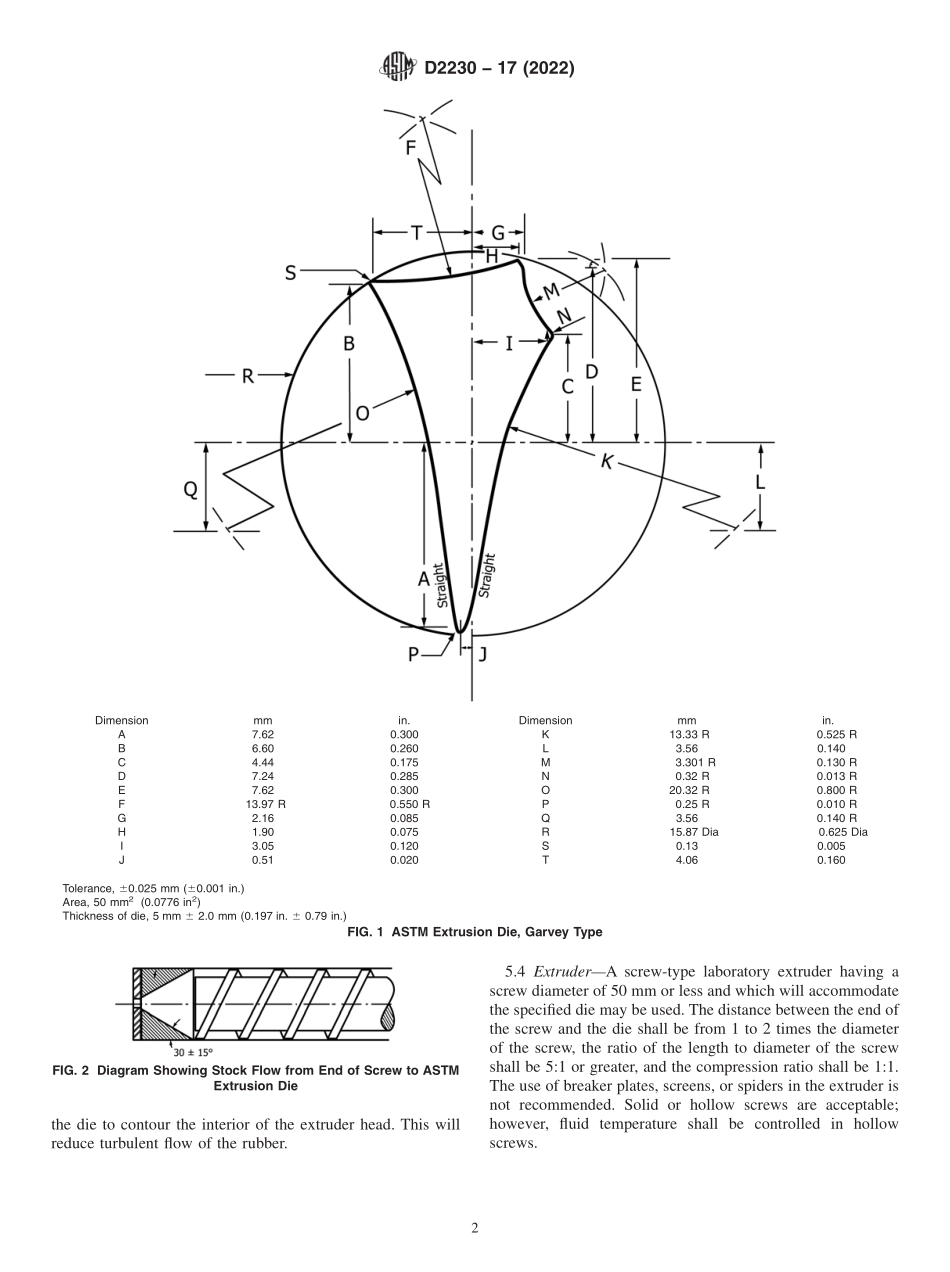

Designation:D2230−17(Reapproved2022)StandardTestMethodforRubberProperty—ExtrudabilityofUnvulcanizedCompounds1ThisstandardisissuedunderthefixeddesignationD2230;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationoftheextrud-abilityofunvulcanizedSBRandNBRrubbercompoundsthroughascrew-typeextruderequippedwithASTMExtrusionDie,Garveytype.Thistestmethodisdesignedtoallowtheobservationoftheappearanceandcontoursoftheextrusion.Ratingsystemsareprovidedalongwithrecipesforcompoundsofknownextrusioncharacteristics.Theutilityofthetestmethodforevaluatingrubbersorcompoundingmaterialsotherthanthoselistedhasnotbeenestablished.Sinceextrusionmachinesdifferamonglaboratories,theprocedureincludestechniquesthatminimizedifferencesbetweenmachines.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D3182PracticeforRubber—Materials,Equipment,andPro-ceduresforMixingStandardCompoundsandPreparingStandardVulcanizedSheetsD3185TestMethodsforRubber—EvaluationofSBR(Styrene-ButadieneRubber)IncludingMixturesWithOilD3187TestMethodsforRubber—EvaluationofNBR(Acrylonitrile-ButadieneRubber)2.2ASTMAdjuncts:AppearanceRatingsPhotographs33...