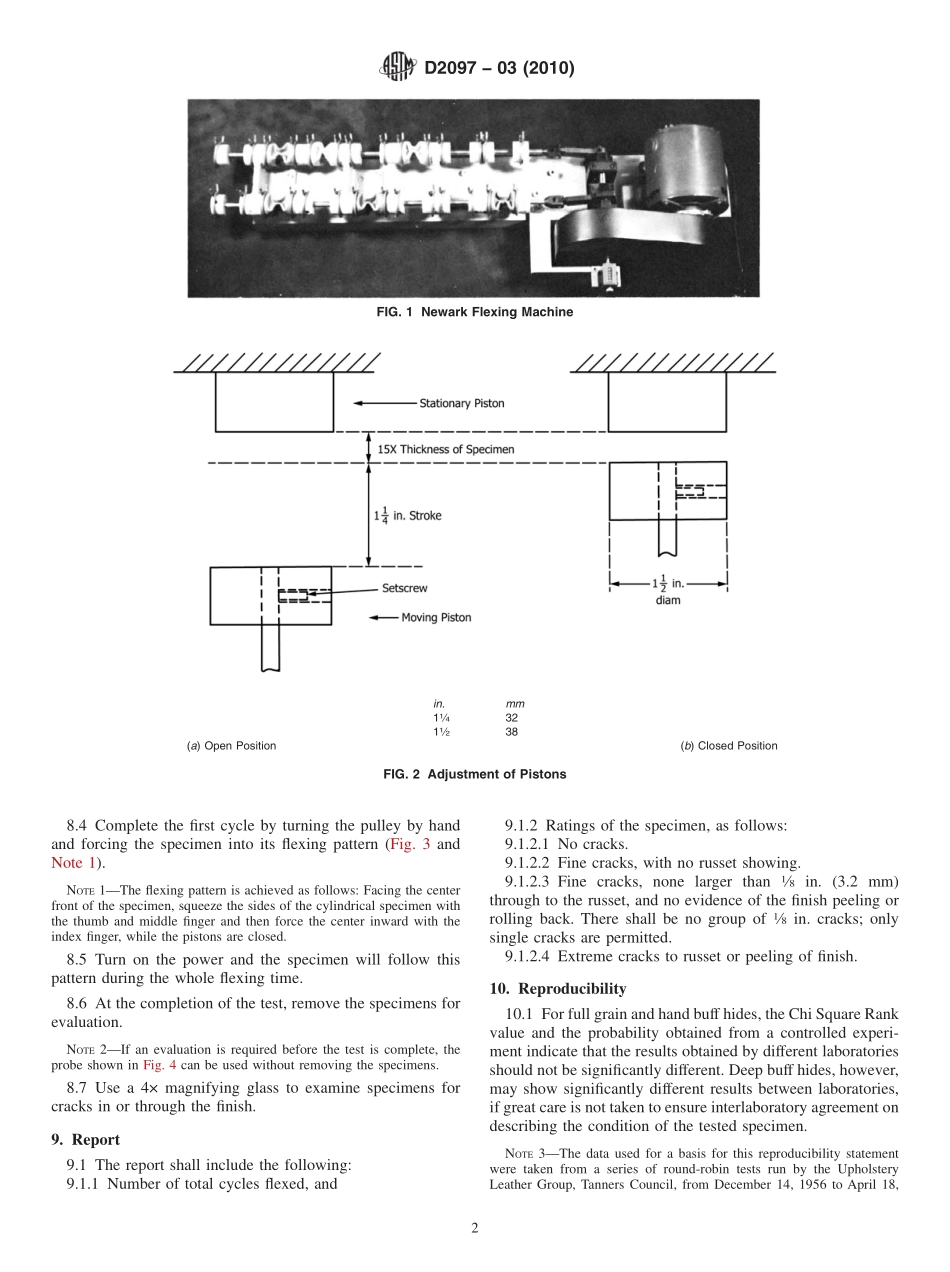

Designation:D2097−03(Reapproved2010)StandardTestMethodforFlexTestingofFinishonUpholsteryLeather1ThisstandardisissuedunderthefixeddesignationD2097;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationoftheflex-ibilityandadhesionofafinishonupholsteryleather.2Thistestmethoddoesnotapplytowetblue.1.2Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:3D1610PracticeforConditioningLeatherandLeatherProd-uctsforTesting3.SummaryofTestMethod3.1Theleatherismechanicallyflexedalternatelyfromaflatpositionintoasingleordoublebend.Attheendofapredeterminednumberofflexingcycles,theleatherisvisuallyinspectedforfinishcracks.4.SignificanceandUse4.1Thistestmethodsimulatestheflexingreceivedbyupholsteryleatherinservice,andcorrelationwithserviceisbelievedtobegood.Boththeresistanceofthefinishtocrackingandadhesionofthefinishtotheleathercanbeevaluated.4.2Theflexingactionreceivedbytheleatherinthismethodismoreseverethanthatgivenbymethodsforshoeupperleather.Thelessseveretestshavelittleutilityintheevaluationofupholsteryleatherfinishes.4.3Thistestmethodissuitable,andhasbeenuseful,inresearch,development,andmanufacturingcontrol.Itisusedasamethodoftestforspecificationacceptance.Sincethisisasubjectivetest,propercorrelationshouldbeestablishedbyinterlaboratoryexperiencepriortouseforspecificationaccep-tance.5.Apparatus5.1NewarkFlexingMachine—Thismachine,4illustratedinFig.1,consistsbasicallyoftwopistons,oneofwhichisstationary,...