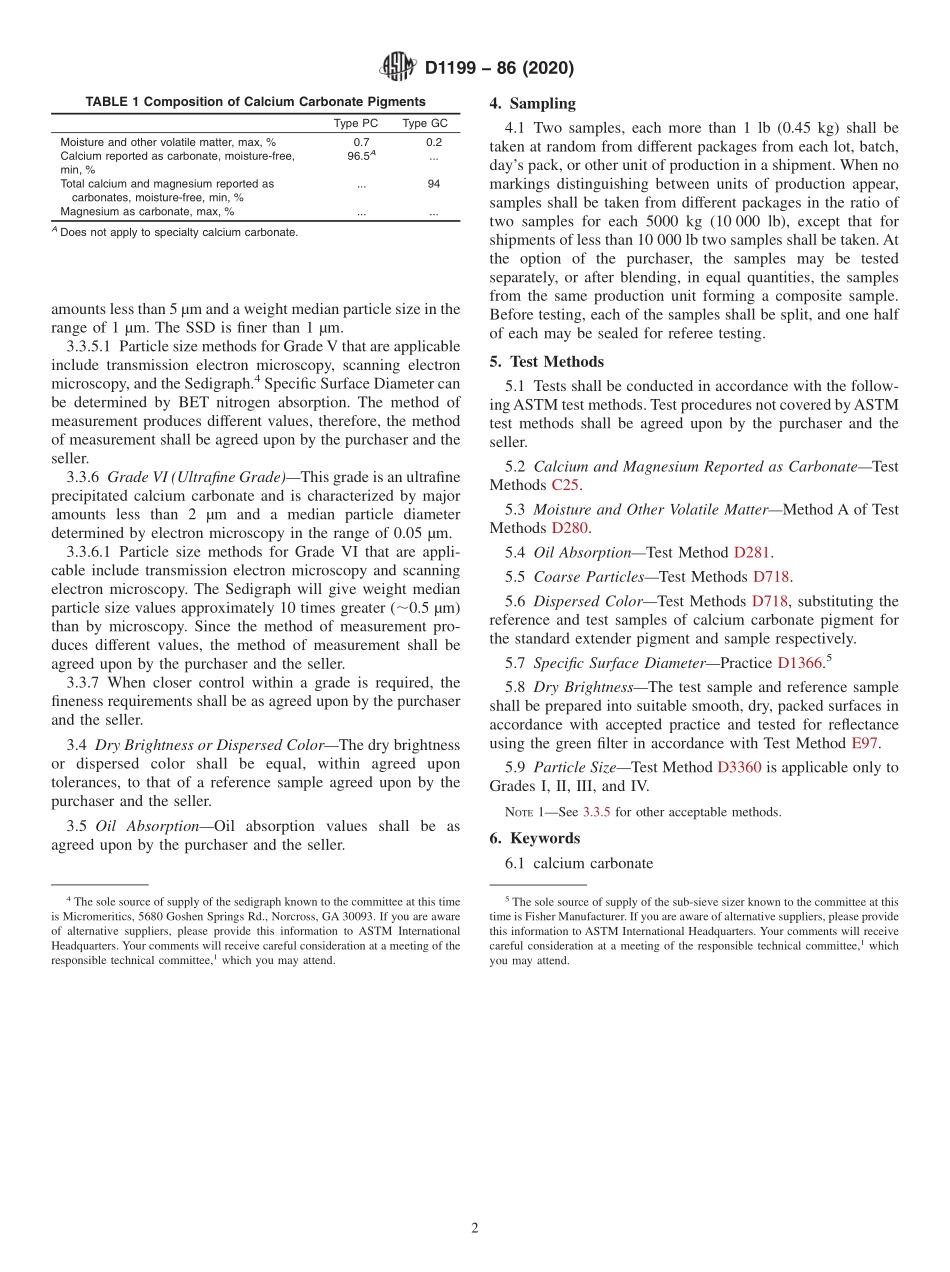

Designation:D1199−86(Reapproved2020)StandardSpecificationforCalciumCarbonatePigments1ThisstandardisissuedunderthefixeddesignationD1199;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thisspecificationcoverstwotypesofhigh-contentcalciumcarbonatepigments,asfollows:1.1.1TypePC—Calciumcarbonateprecipitate,preparedeitherbycompletesolutionorbycarbonationoflime.1.1.2TypeGC—Groundmineralproduct.1.2Sixgradesofpigments,basedonparticlesize(see3.3)arecovered.1.3ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2C25TestMethodsforChemicalAnalysisofLimestone,Quicklime,andHydratedLimeD280TestMethodsforHygroscopicMoisture(andOtherMatterVolatileUndertheTestConditions)inPigmentsD281TestMethodforOilAbsorptionofPigmentsbySpatulaRub-outD718TestMethodsforAnalysisofAluminumSilicatePigmentD1366PracticeforReportingParticleSizeCharacteristicsofPigmentsD3360TestMethodforParticleSizeDistributionbyHy-drometeroftheCommonWhiteExtenderPigments(Withdrawn2003)3E97MethodofTestforDirectionalReflectanceFactor,45-Deg0-Deg,ofOpaqueSpecimensbyBroad-BandFilterReflectometry(Withdrawn1991)33.CompositionandProperties3.1Thepigmentmaybepreparedbychemicalprecipitationorbythefinegrindingofnaturalcalciumcarbonatecontainingminerals.Ifadditionalagentsareusedoranysurfacetreatmentisgiven,theirpurposeshallbeindicated;acceptanceshallbeasagreeduponbythepurchasera...