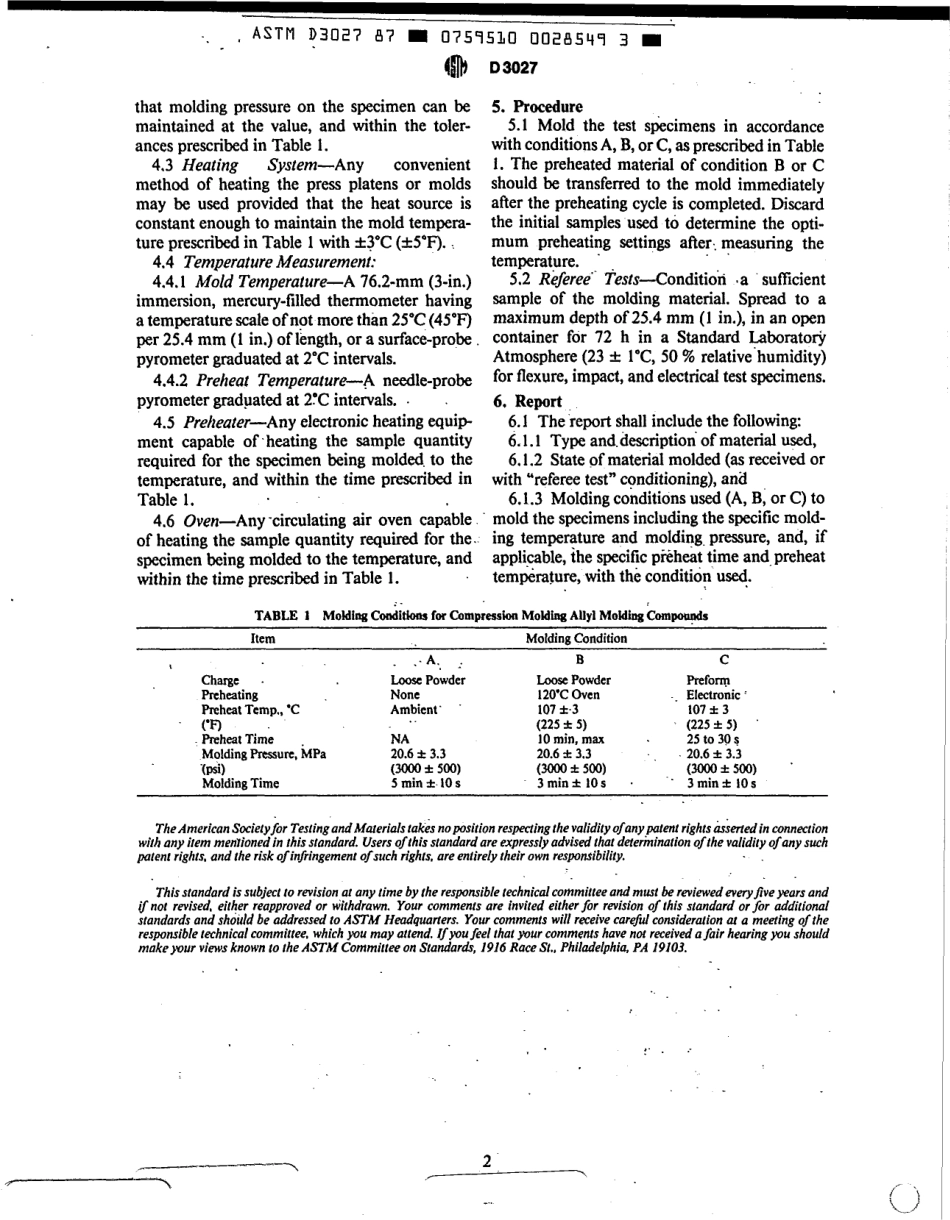

‘VU’AMERICANSOCIETYFORTESTINGANDMATERIALS1916RaceSt.,Philadelphia,Pa.19103ReprintedfromtheAnnualBookofASTMStandards,CopyrightASTMIfnotlistedinthecurrentcombinedindex,willappearinthenextedition..StandardPracticeforCOMPRESSIONMOLDINGTESTSPECIMENSOFALLYL.MOLDINGCOMPOUNDS‘ThisstandardisissuedunderthefixeddesignationD3027;thenumberimmediatelyfollowingthedesiktionindicatesthcyearoforiginaladoptionor,inthecaseofrevision.theyearoflastrevision.Anumberinparenthesesindicamtheyearoflastrrappcoval.Asuperscr¡ptcpdon(e)indicatesanedditor¡alchangeincethelastrevidonorreapprod.l.SCoDeertiesobtainedwithdifferentcompounds,orbe-tweendifferentbatchesofthesamecompound.3.2Ifthemoldedspecimensshowevidenceoflowdensityareasduetotrappedgases,thespec-imensshouldbediscarded.Abreathestepshould:beusedinmoldingnewspecimens.Itiscritical.toholdtoarelativelybriefbreathecycletoavoidprocuringthegranulesbeforefullpmisapplied,Suchaconditionwouldresultinpoorlyknittedareasandlowerstrengthinthemoldedspecimen.1.1Thispracticecoverstheproceduretobeused.forcompressionmoldingthetestspecimensrequiredforSpecificationD1636.inSIunitsaretoberegardedasstandard.Thevaluesinparenthesesaregivenforinformationonly.1.3Thisstandardmayinvolvehazardousma-terials,operations,andequipmenï.Thissïandarddoesnotpurportioaddressallofihesafetuprob-lemsassociaïedwithitsuse.Itistheresponsibil-1.2Thevaluesiïyoftheuserofthissïandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimiïationspriortouse.2.ReferencedDocuments2.1ASTMStandards:D647PracticeforDesignofMoldsforTestSpecimensofPlasticMoldingMaterials2D958PracticeforDeterminingTemperaturesofStandardASTMMoldsforTestSpeci-mensofPlastic2D1636SpecificationforAllylMoldingCompounds3D2863TestMethodforMeasuringtheMini-mumOxygenConcentrationtoSupportCandle-LikeCombustionofPlastics(Oxy-genIndex)33.SignificanceandUse4.Apparatus4.1-Molds(SeeNotes1and2)4.1.1Impact,Flexural,FlameResistance,andOxygenIndexSpecimens-Usethesinglebar,singlecavity,positi...