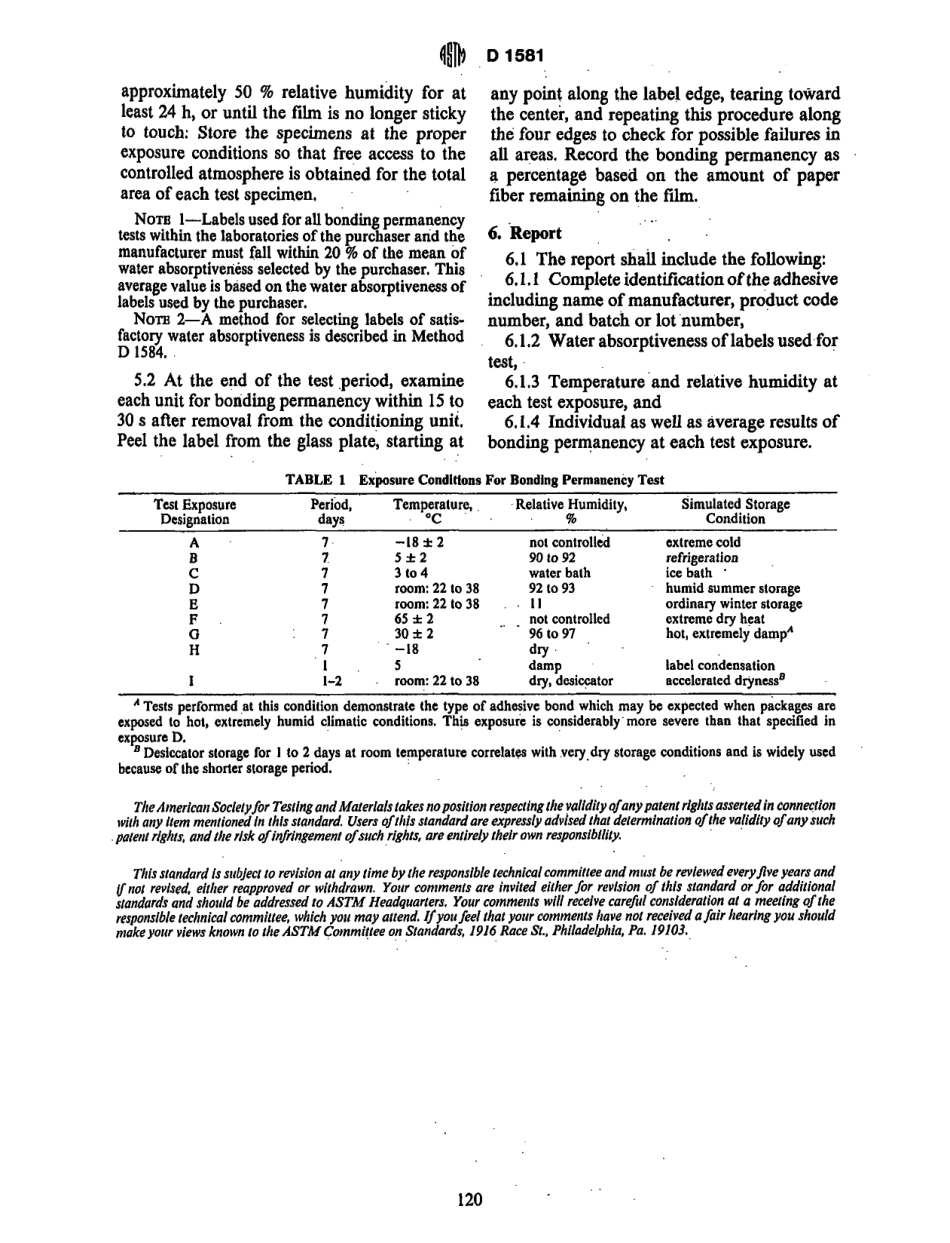

~~~.Designation:D1581-60(Reapproved1984)StandardTestMethodforBONDINGPERMANENCY·OFWATER-ORSOLVENT-.SOLUBLELIQUIDADHESIVESFORLABELINGGLASS·.BOTTLES1~~standard.isissue~underthefixed.~esignationD1581ithenumberimmediatelyfollowingthedesfgnationindicatestheearof~ngmalad~ption.or,Int~e~seofreVISIon,.theyearoflastrevision.Anumberinparenthesesindicafesthe"yeai'oflastreap~rOValsuperscnptepsilon(e)mdlcatesaneditorialchangesincetbelastrevisionorreapproval...........1.Scope1.1Thismethodcoversthedeterminationofthebondingpermanencyofdextrin,casein,starch,animalgelatin,andotherliquidadhesives(excludingpressure-sensitivetypes)usedfor-ap-.plyingprintedpaperlabelstoglassbottles...1.2Thisstandardmayinvolvehazardousma-terials.operations,andequipment.Thisstandarddoesnotjmrporltoaddressallo/thesafetyprob-lemsassociatedwitlzitslise.Itistheresponsibil-ity0/whoeverusesthisstandardtoconsultandestablishappropriatesafetyandhealtiz.practicesanddeterminetheapplicabilityo/regulatorylimi-tationspriortolise.2.ApplicableDocuments2.1ASTMStandard:D1584TestMethodforWaterAbsorptiveness·ofPaperLabels2.ditiorisof22to38°Cand91to93%relativehumidity..3.5.2Potassiumsulfateforconditionsof30·0C·and96to.970/0.relativehumidity.3.5.3.Lithium.chlorideforconditionsof22to38°Cand11%relativehumidity...4.·Sampling.4.1Theadhesivesampleshallb~a0.9litre(l-qt)aliquotconsistiilgofacompositetaken,whenpossible,fromthreeormoreseparatecontainerschosenatrandom.Alsotakesamplesfrom~ontainerswhich~ppeartobenonrepre-·sentahveandtestseparately.Beforeasampleiswithdrawn,miXtheadhesivestouniformConsistency.Imni~dhitelyplacethesample.inanair-tightglassjaruntilreadyfortesting.S.Procedure5.1.Useonlythose.labelswithintheselected3..Apparatus.rangeofwaterabsorptivenessforeachtest3.1FirmApplicator,tubeorrodtypetogive..(Notes.1and.2).SelectfromTable1thoseawetfUmthicknessof0.025to0.038mm(0.001expo~ur~whichthepackagemayencounterto0.0015in.).aftershipment..Thepurchaserand.themanu-3.2GlassPlatesofsmoothplateglass,sizefacturershouldagreeon...