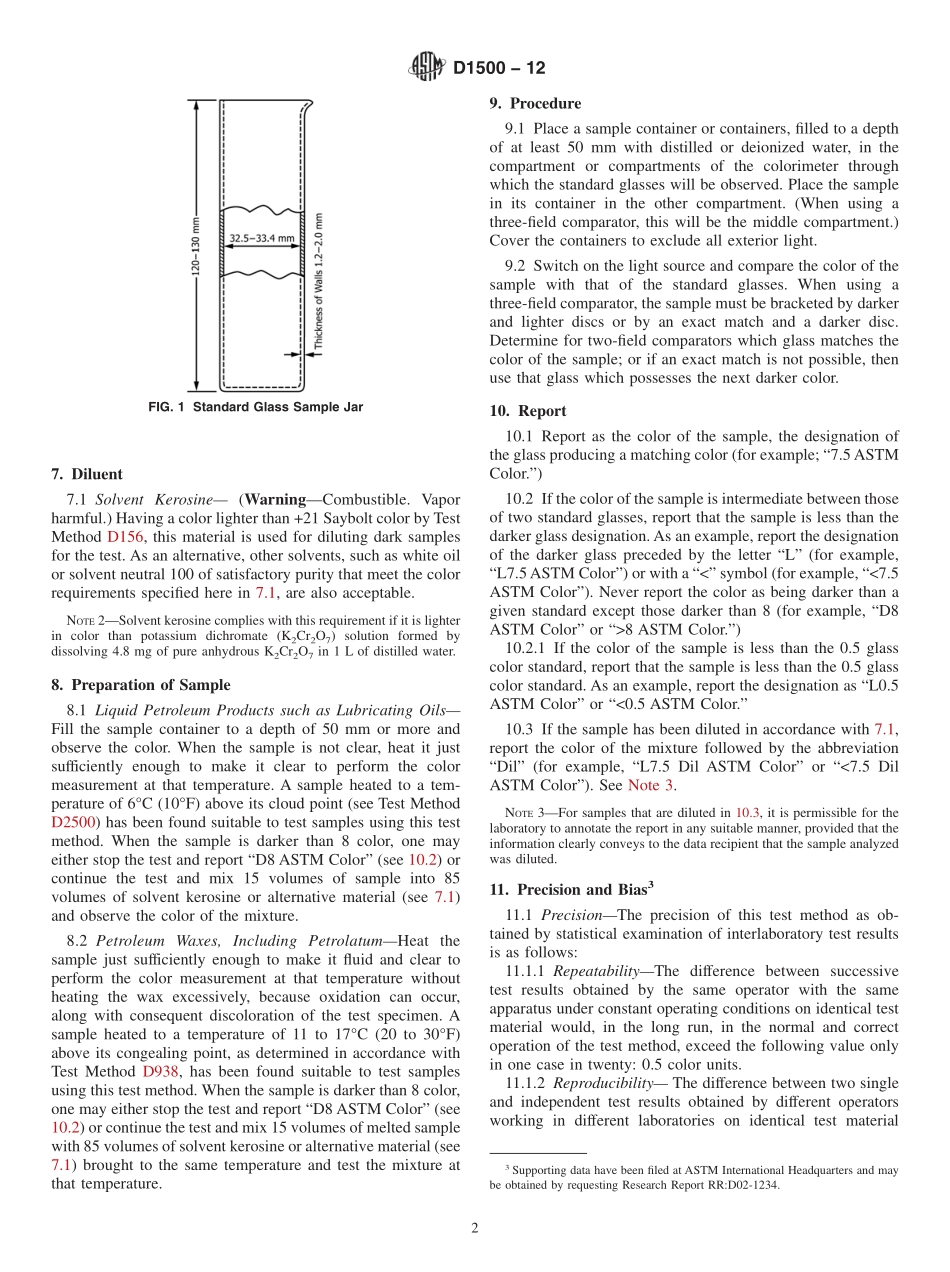

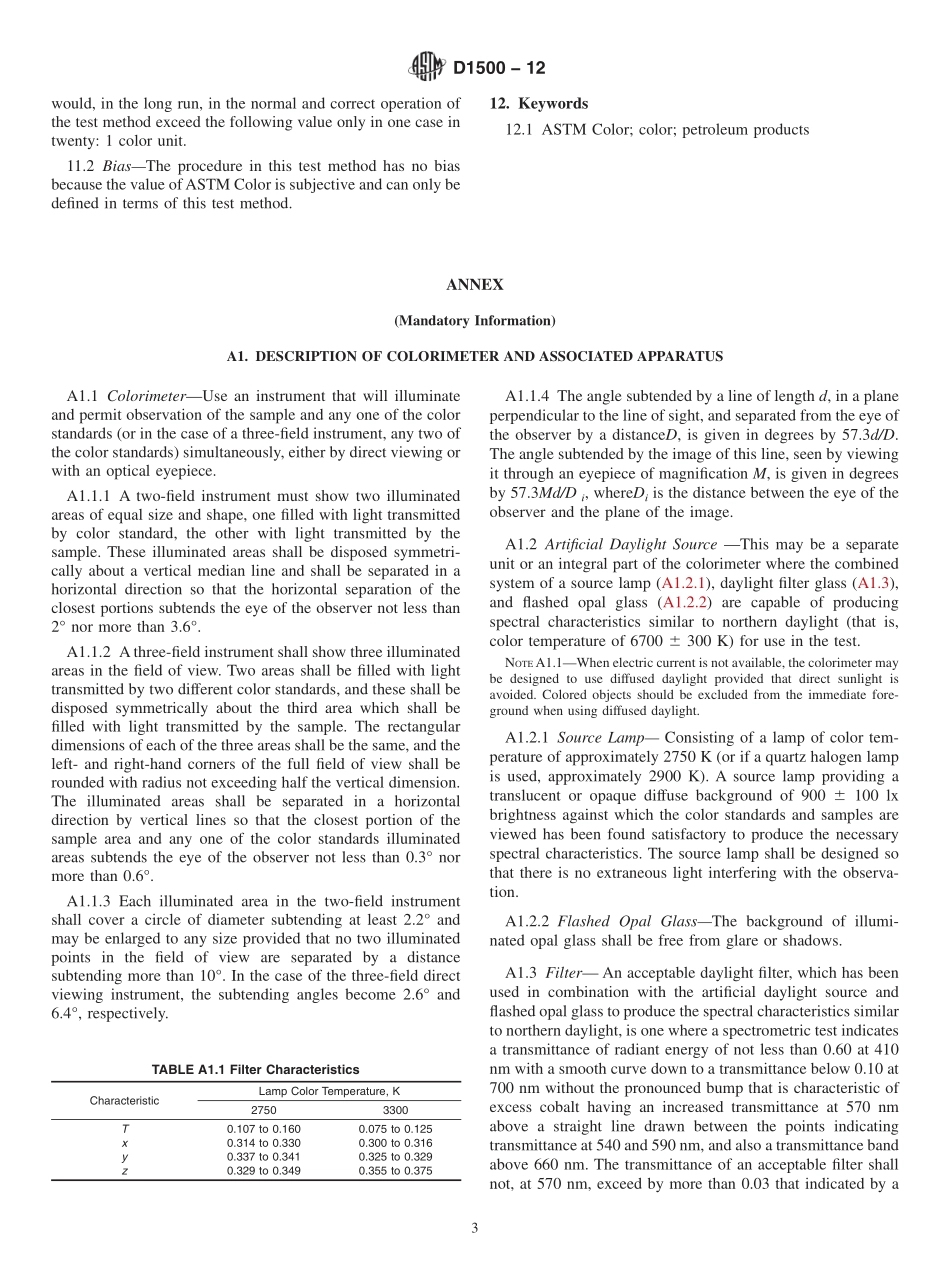

Designation:D1500−12Designation:196/97StandardTestMethodforASTMColorofPetroleumProducts(ASTMColorScale)1ThisstandardisissuedunderthefixeddesignationD1500;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thistestmethodcoversthevisualdeterminationofthecolorofawidevarietyofpetroleumproducts,suchaslubricatingoils,heatingoils,dieselfueloils,andpetroleumwaxes.NOTE1—TestMethodD156isapplicabletorefinedproductsthathaveanASTMcolorlighterthan0.5.1.2Thistestmethodreportsresultsspecifictothetestmethodandrecordedas“ASTMColor.”1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D156TestMethodforSayboltColorofPetroleumProducts(SayboltChromometerMethod)D938TestMethodforCongealingPointofPetroleumWaxes,IncludingPetrolatumD2500TestMethodforCloudPointofPetroleumProductsD4057PracticeforManualSamplingofPetroleumandPetroleumProducts3.SummaryofTestMethod3.1Usingastandardlightsource,aliquidsampleisplacedinthetestcontainerandcomparedwithcoloredglassdisksranginginvaluefrom0.5to8.0.Whenanexactmatchisnotfoundandthesamplecolorfallsbetweentwostandardcolors,thehigherofthetwocolorsisreported.4.SignificanceandUse4.1Determinationofthecolorofpetroleumproductsisusedmainlyformanufacturingcontrolpurposesandisanimportantqualitycharacteristic,sincecolorisreadilyobservedbytheuseroftheproduct.Insomecases,thecolormayserveasanindicationofthedegreeofrefinementofthematerial.Whenthecolorrangeofaparticularproductisknown,avariationoutsidetheestablishedrangemayindicatepossiblecontaminationwithanother...