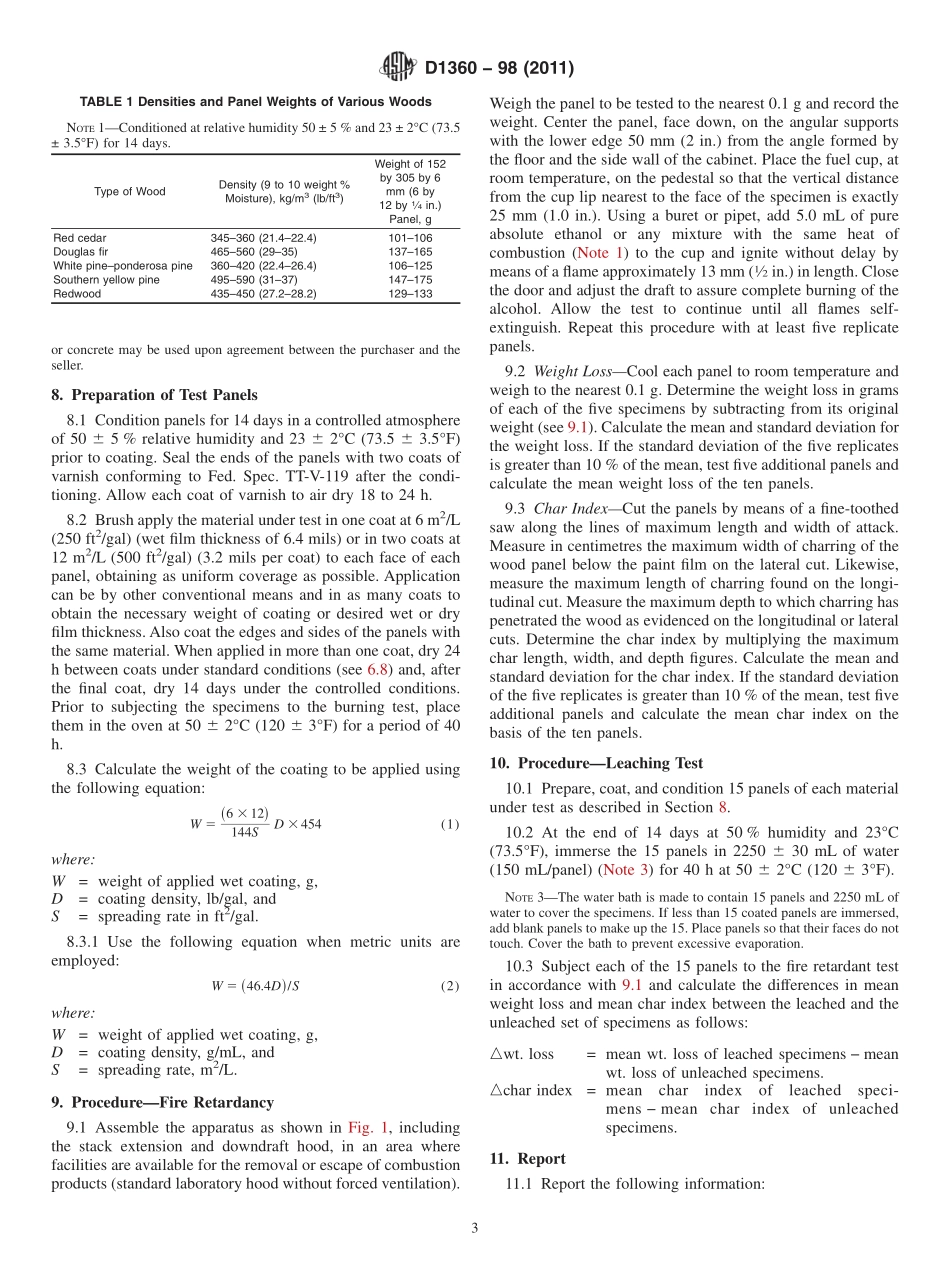

Designation:D1360−98(Reapproved2011)StandardTestMethodforFireRetardancyofPaints(CabinetMethod)1ThisstandardisissuedunderthefixeddesignationD1360;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethoddeterminesquantitativelythefireretardantpropertiesofacoatingorcoatingsystemonawoodsurfaceandtheleachingeffectofwateronthefireretardancyofthecoatingorcoatingsystem.Specifically,thistestmethoddeterminestheweightlossandcharindexofcoatedpanelssubjectedtoaflameandtheeffectofleachingofthecoatingontheseparameters.1.2Thistestmethodshouldbeusedsolelytomeasureanddescribethepropertiesofmaterials,products,orsystemsinresponsetoheatandflameundercontrolledlaboratorycondi-tionsandshouldnotbeconsideredorusedforthedescription,appraisal,orregulationofthefirehazardofmaterials,products,orsystemsunderactualfireconditions.1.3ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1FederalStandard:2Fed.Spec.TT-V-119—VarnishSpar,PhenolicResin2.2MilitaryStandard:2Mil.Spec.MIL-A-22397—AdhesivePhenol,andResorci-nalResinBaseforMarineUse2.3ASTMAdjuncts:CabinetAssembly33.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1fireretardancy,n—inpaint,theabilityofapainttoretardthespreadofaflameovercoatedsubstrateusuallyatthesacrificeofthepaintfilm.4.SummaryofTestMethod4.1FireRetardancy—Panelsareconditionedbeforeandaftercoatingwiththematerialundertest.Theyaresubjectedtoaflamefromasmallamountofburningalcoholorothersolvent,andtheweightlossandcharindexaredetermined.4...