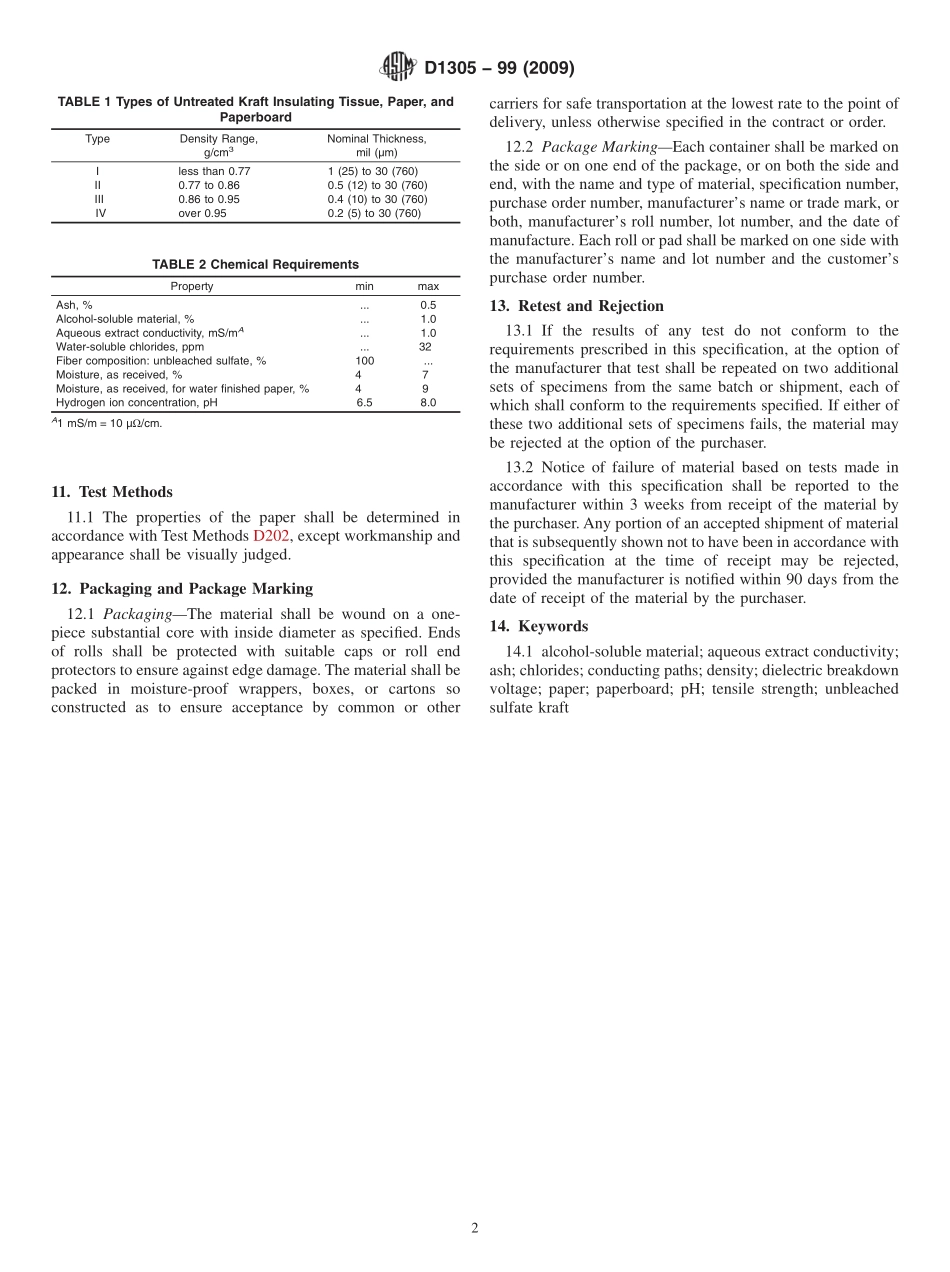

Designation:D1305−99(Reapproved2009)StandardSpecificationforElectricalInsulatingPaperandPaperboard—Sulfate(Kraft)LayerType1ThisstandardisissuedunderthefixeddesignationD1305;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoverselectricalgradeunsized,un-bleachedsulfatepaperandpaperboardforuseaslayerinsula-tionincoils,transformers,andsimilarapparatus.Otherappli-cationsmayinclude,butarenotlimitedto,turninsulation,slotliners,wedges,phaseinsulation,andseparatorpapersinstrandedwire/cableconstructions.Tissueforthemanufactureofcapacitorsisnotincludedinthisspecification.Othercommonlyuseddesignationsinclude:1.1.1SoftCoilWrap,1.1.2DenseCoilWrap,1.1.3KraftCoilInsulation,1.1.4Dry-FinishedKraft,and1.1.5Water-FinishedKraft.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.2.ReferencedDocuments2.1ASTMStandards:2D202TestMethodsforSamplingandTestingUntreatedPaperUsedforElectricalInsulationD1711TerminologyRelatingtoElectricalInsulation3.Terminology3.1Definitions—Fordefinitionsoftermsusedinthisstandard,refertoTerminologyD1711.4.Classification4.1Fourtypesofpaperandpaperboardarecoveredbythisspecification,asshowninTable1.Thematerialisavailableinsheets,pads,orrolls.5.OrderingInformation5.1Ordersshallspecifythetype,includingwhetherwaterfinishornot(seeNote1),nominalthickness,form,width,length(forsheets),nominaloutsidediameter,andcoreinsidediameter(forrolls).NOTE1—WaterfinishisnotavailablewithcertaincombinationsofKrafttypeandthickness.Ingeneral,waterfinishisrestrictedtopaperandpaperboardinthehigherdensityranges,thatis,TypesIIIandIV.6.Materials6.1Thematerialshallbenaturalunbleachedsulfatepaperorpaperboard,freeofdyes,pigment...