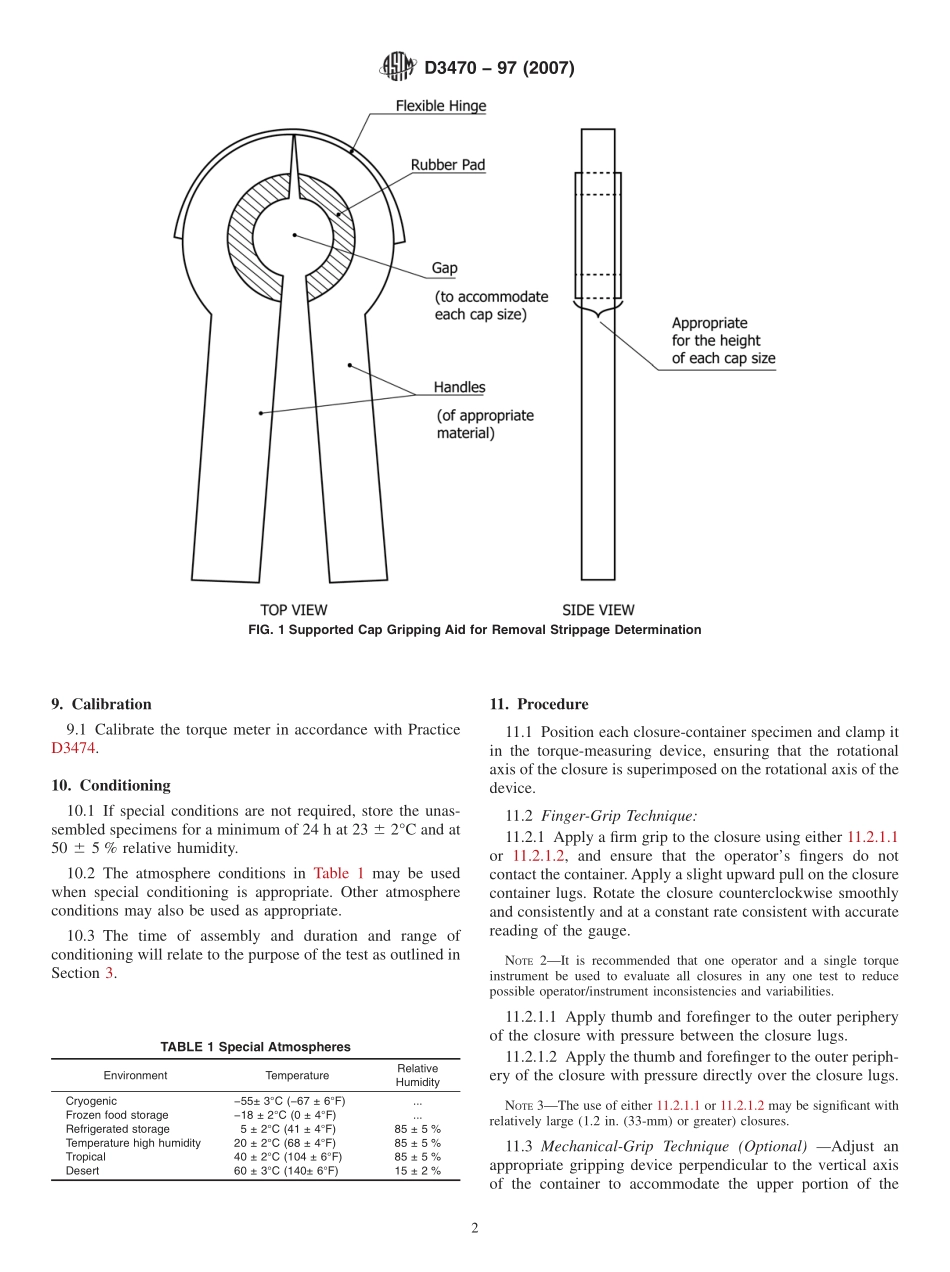

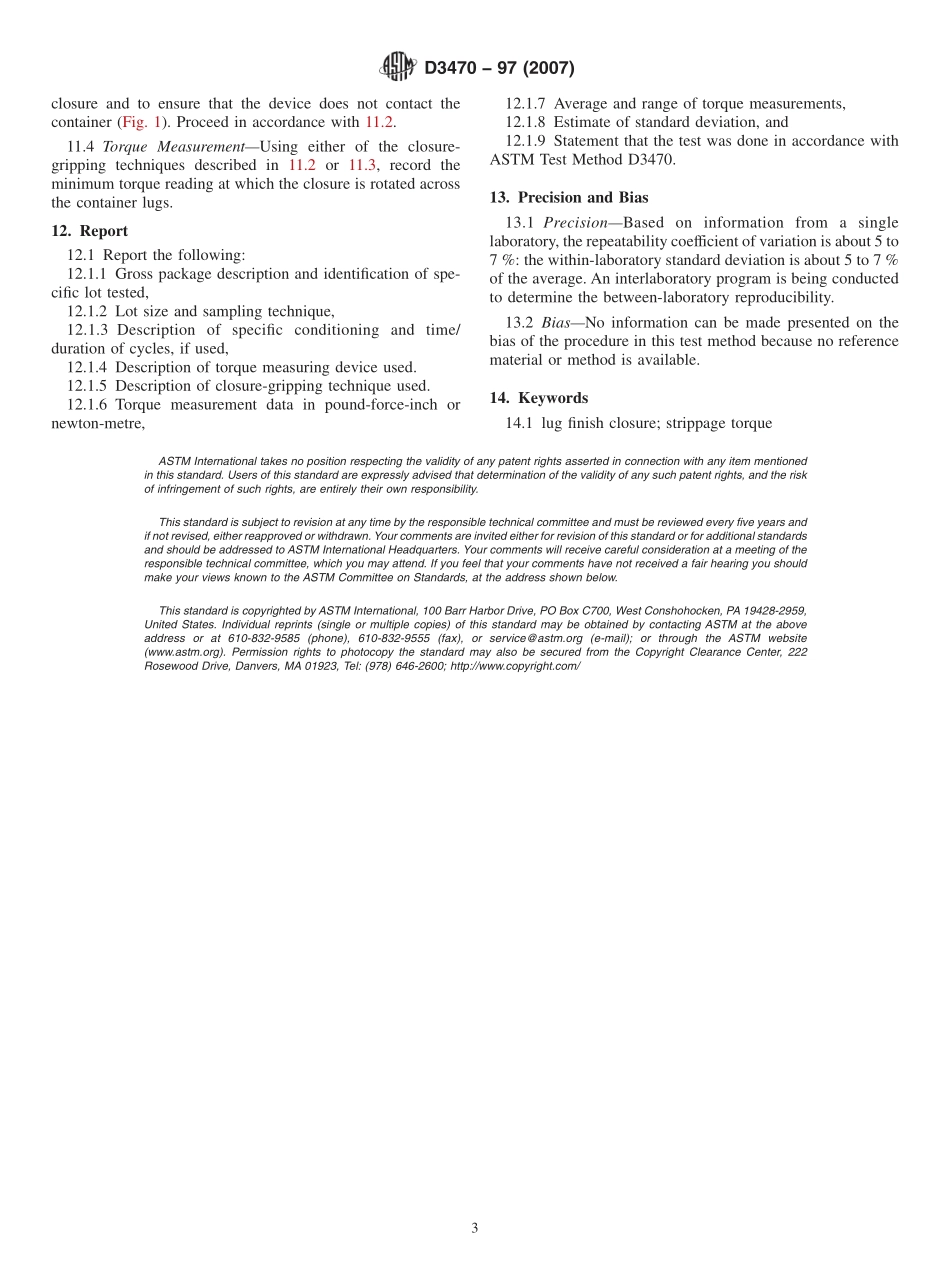

Designation:D3470−97(Reapproved2007)StandardTestMethodforMeasurementofRemovalLugStrippageofTypeIIAChild-ResistantClosures1ThisstandardisissuedunderthefixeddesignationD3470;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationoftheforcerequiredtocauseadownward-force-while-turninglug-finishclosuretoberotatedacrossthecontainerfinishlugs(strippage)withoutdownwardforcebeingappliedtotheclosure(TypeIIAclosures).1.2Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D3474PracticeforCalibrationandUseofTorqueMetersUsedinPackagingApplicationsD3475ClassificationofChild-ResistantPackages3.Terminology3.1Definitions:3.1.1typeIIAchild-resistantclosure—alugfinishclosurerequiringarandompushdownwhileturning.(SeeClassifica-tionD3475.)3.2DefinitionsofTermsSpecifictoThisStandard:3.2.1strippagetorque—themomentofforcewhichisre-quiredtoproducerotationoftheclosureoverthecontainerlugswhileexertingnodownwardforce.4.SummaryofTestMethod4.1Thistestmethodconsistsofsecuringacappedcontainer(aftersuitablepreconditioning)inatorque-measuringdeviceandrotatingtheclosure,usingmechanicalornonmechanicalaid,todeterminethetorqueneededtorotatetheclosureacrossthecontainerlugs.Nodownwardforceisapplied.4.2Usingsufficientsampling,theaveragestrippageforceandtherangearedeterminedforagivenlotofsamples.Torquemeasurementsareinunitsofpound-force-inchornewton-metre.5.SignificanceandUse5.1Thistestmethodmaybeusedasastandardtestinthecomparisonofagivensizeanddesignlug-stylechild-resistantclosuretomanufacturerspecifications,andinthecomparisonofsimilarcl...