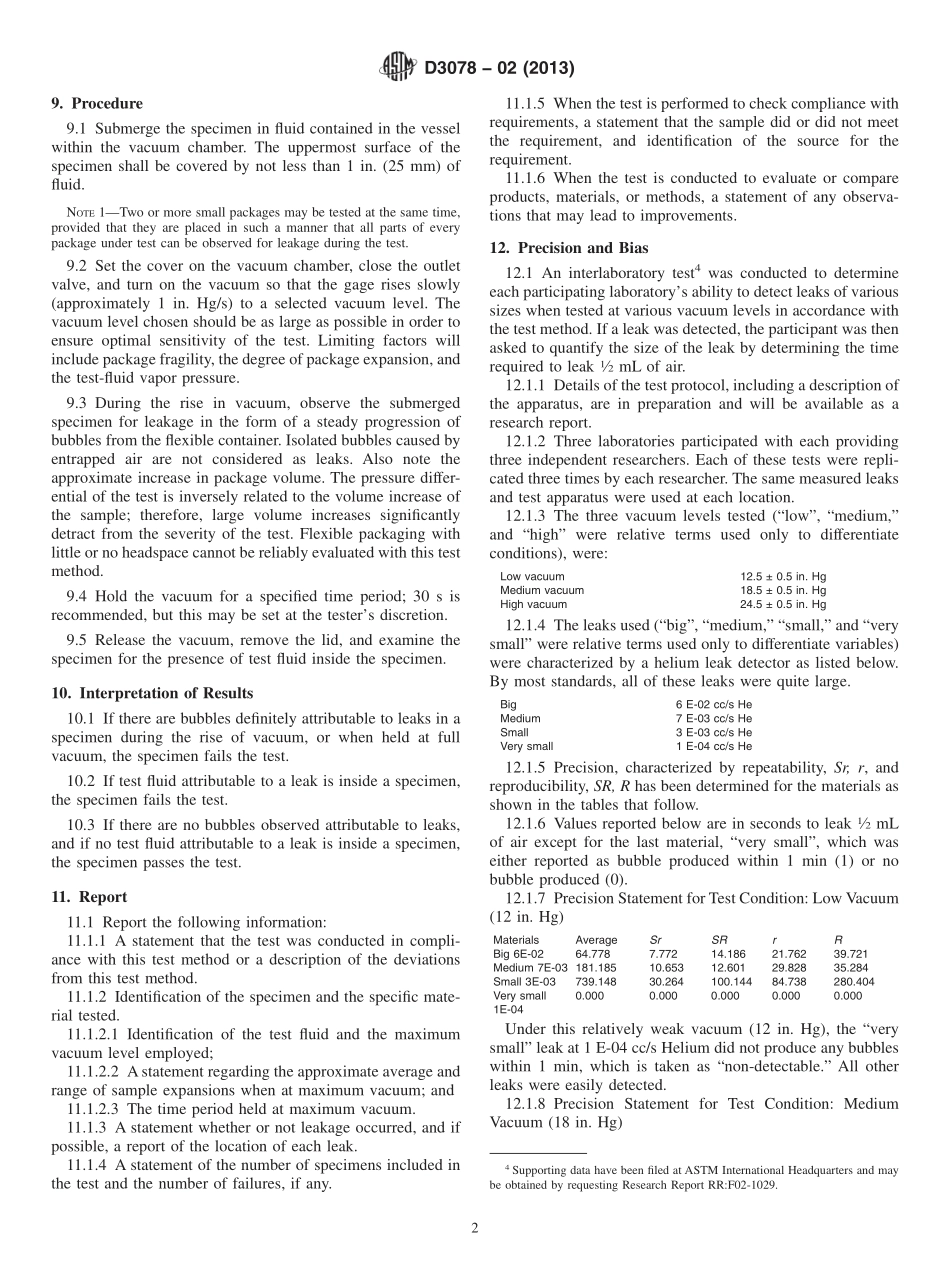

Designation:D3078−02(Reapproved2013)StandardTestMethodforDeterminationofLeaksinFlexiblePackagingbyBubbleEmission1ThisstandardisissuedunderthefixeddesignationD3078;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationofgrossleaksinflexiblepackagingcontainingaheadspacegas.Testsensi-tivityislimitedto1×10−5atmcm3/s(1×10−6Pam3/s)orevenlesssensitiveasindicatedinarecentinterlaboratorytest(reportedinSection12).1.2Smallleaksmaynotbedetectedbythisprocedure.Viscoelasticeffectsontheproducts,orentrappedair,becomesignificantandpreventpassagethroughsmallopenings.Posi-tivepressureinsidethepouchafterthevacuumisdrawnmayforcetheproducttoplugsmallleaks.Thesizeoftheleakthatcanbedetectedisdependentupontheproductscontained,thenatureofthepackagingmaterial,andthetestparametersselected.1.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2E425DefinitionsofTermsRelatingtoLeakTesting(With-drawn1991)3E515PracticeforLeaksUsingBubbleEmissionTechniquesF98RecommendedPracticeforDeterminingHermeticityofElectronDevicesbyaBubbleTest(Withdrawn1990)33.Terminology3.1Definitions:3.1.1leak—anyopeninginaflexiblepackagethat,contrarytointention,eitherallowsthecontentstoescapeorsubstancestoenter.4.Apparatus4.1VacuumChamber—Anytransparentcontainercapableofwithstandingapproximatelyoneatmospherepressuredifferential,fittedwithavacuum-tightcover.Avacuumgage,...