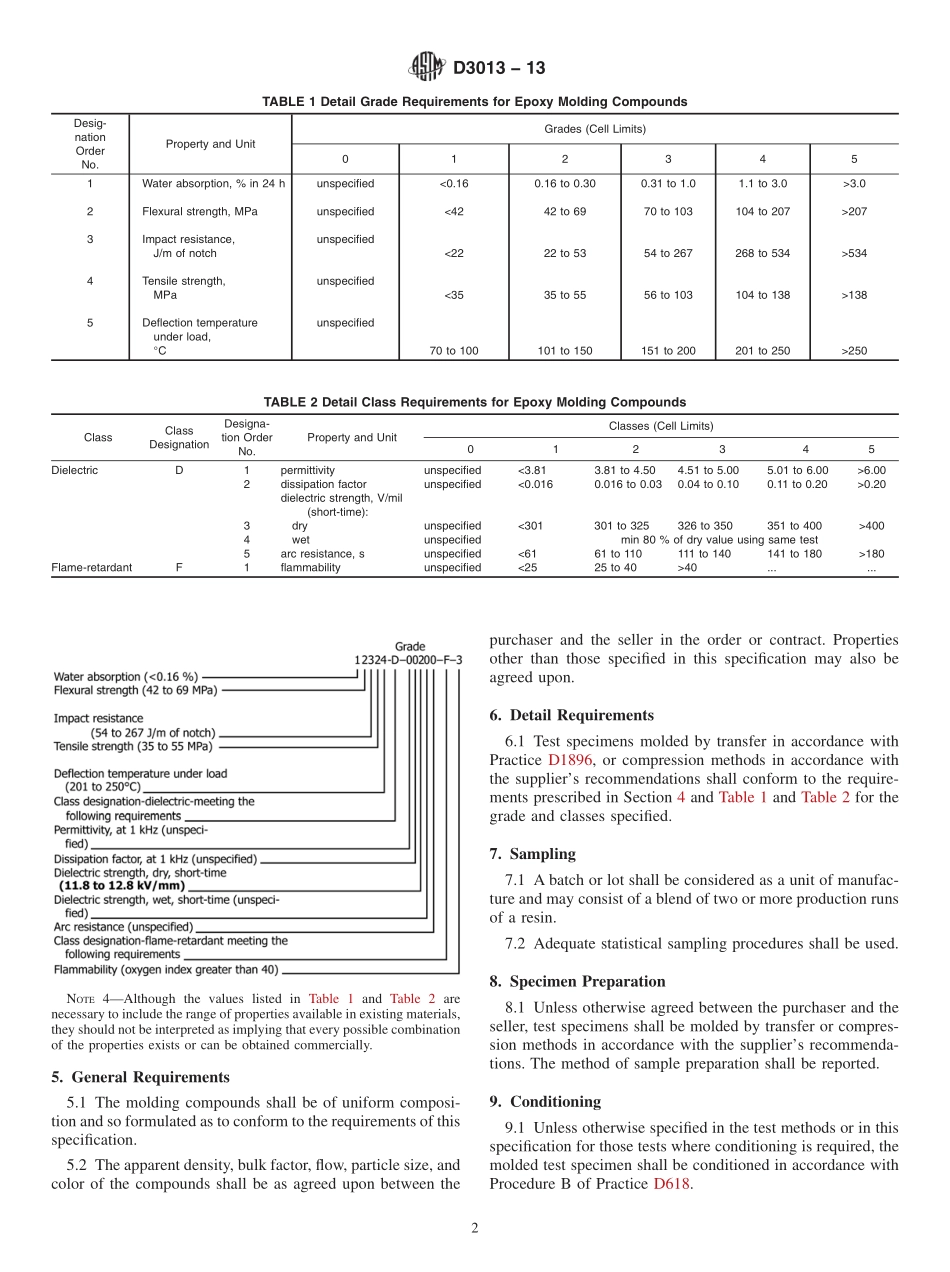

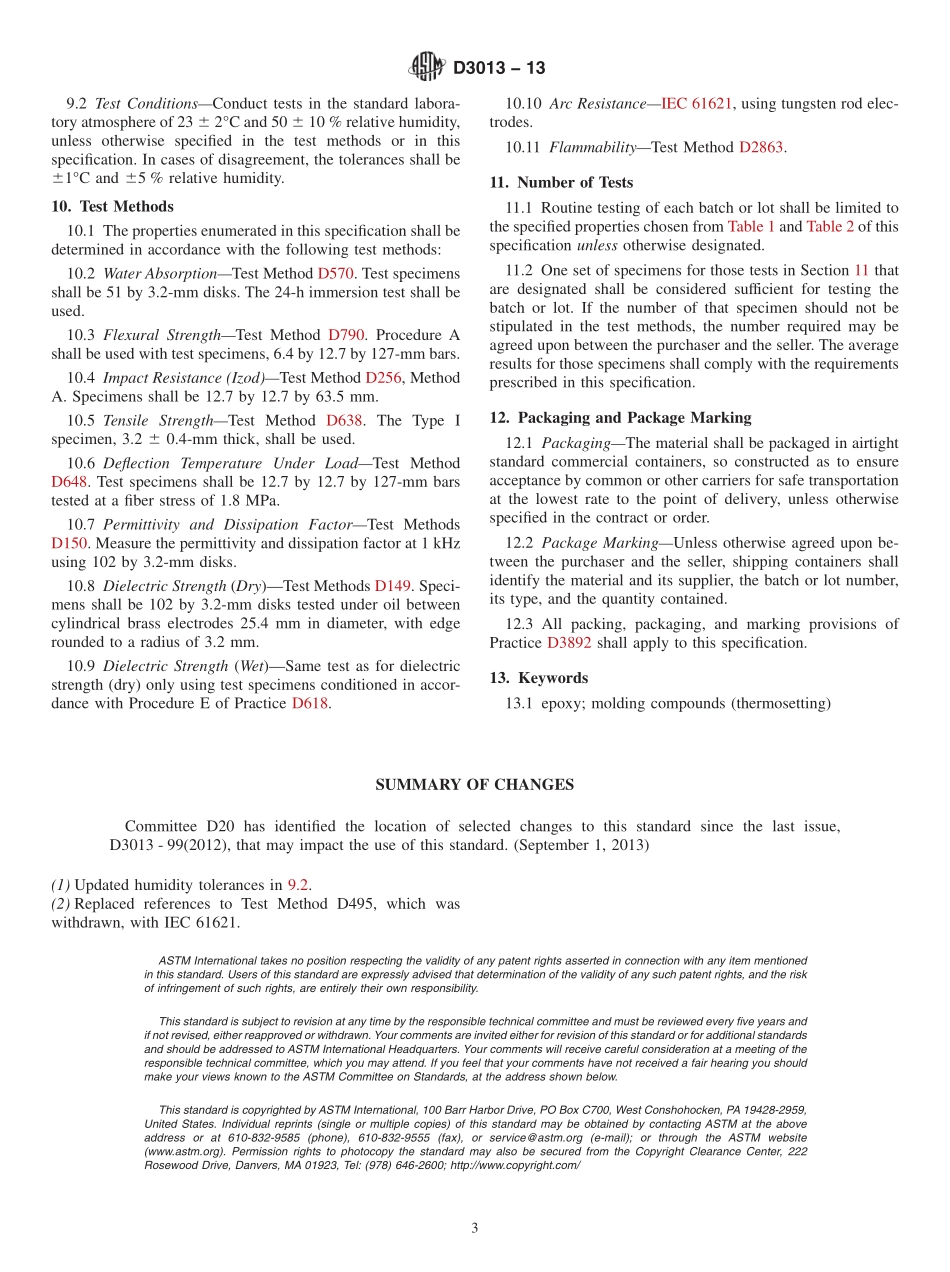

Designation:D3013−13StandardSpecificationforEpoxyMoldingCompounds1ThisstandardisissuedunderthefixeddesignationD3013;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thisspecificationcoversrequirementsforepoxyther-mosettingmoldingcompounds.Itprovidesfortheiridentification,qualitycontrol,andpurchaseinsuchamannerthatthepurchaserandthesellercanagreeonthesubstantialsimilarityofdifferentcommerciallotsorshipments.1.2Thecompoundscoveredunderthisspecificationconsistofmixturesorblendsofepoxyresinsandcuringagentsintimatelycombined,inanunreactedorpartiallyreactedcondition,withfillers,reinforcements,colorants,andotherchemicalagents.1.3ThevaluesstatedinSIunitsaretoberegardedasthestandard.NOTE1—Thepropertiesincludedinthisspecificationarethoserequiredtoidentifythekindsofmoldingcompoundscovered.Theremaybeotherrequirementsnecessarytodefineparticularcharacteristics.Thesewillbeaddedtothespecificationastheirinclusionbecomesgenerallydesirableandthenecessarytestdataandmethodsbecomeavailable.NOTE2—ThereisnoknownISOequivalenttothisstandard.2.ReferencedDocuments2.1ASTMStandards:2D149TestMethodforDielectricBreakdownVoltageandDielectricStrengthofSolidElectricalInsulatingMaterialsatCommercialPowerFrequenciesD150TestMethodsforACLossCharacteristicsandPermit-tivity(DielectricConstant)ofSolidElectricalInsulationD256TestMethodsforDeterminingtheIzodPendulumImpactResistanceofPlasticsD570TestMethodforWaterAbsorptionofPlasticsD618PracticeforConditioningPlasticsforTestingD638TestMethodforTensilePropertiesofPlasticsD648TestMethodforDeflectionTemperatureofPlasticsUnderFlexuralLoadintheEdgewisePositionD790TestMethodsforFlexuralPropertiesofUnreinforcedandReinforcedPlasticsandElectricalInsulatingMateri-alsD883Terminol...