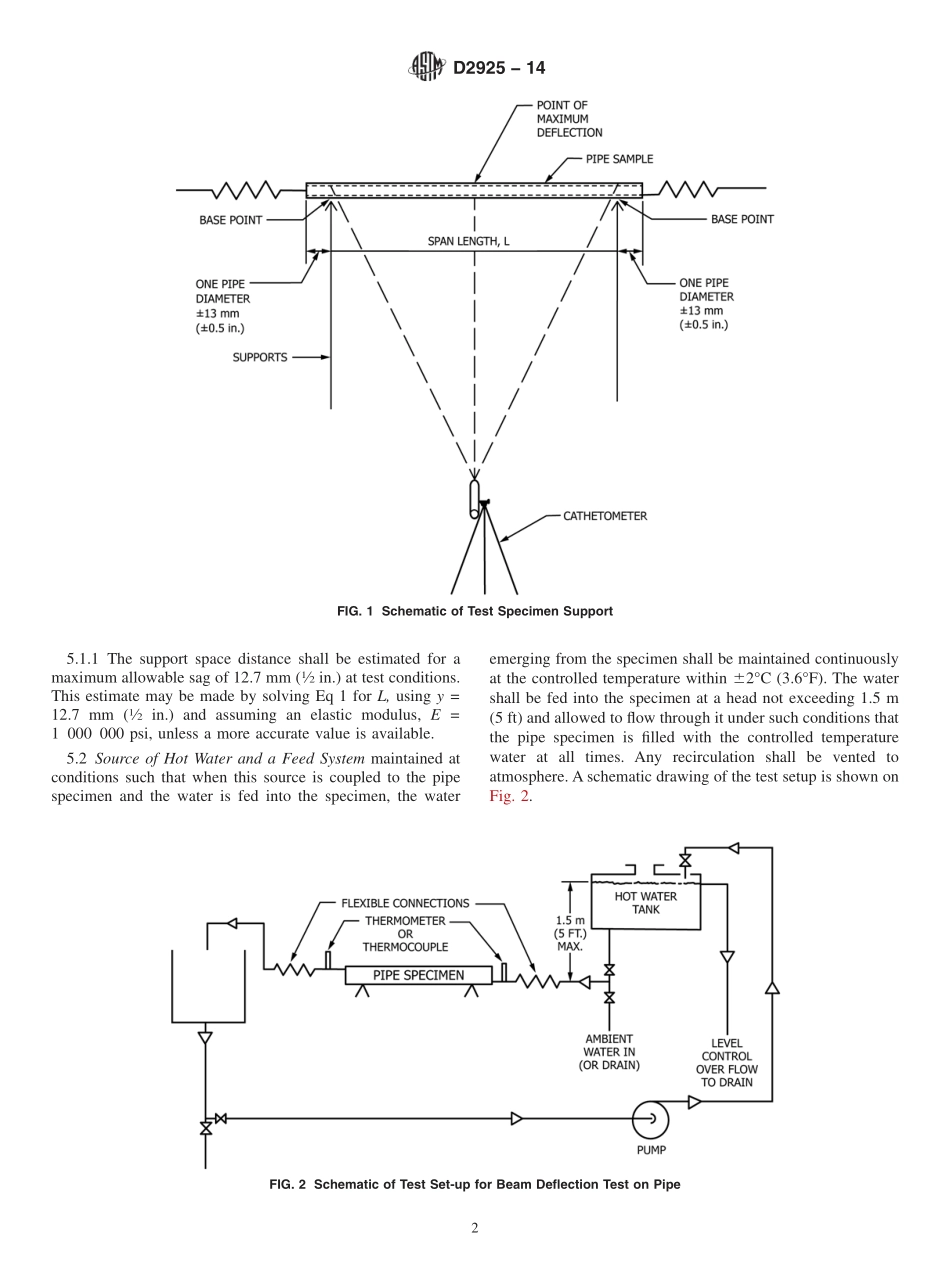

Designation:D2925−14AnAmericanNationalStandardStandardTestMethodforBeamDeflectionof“Fiberglass”(Glass-Fiber-ReinforcedThermosettingResin)PipeUnderFullBoreFlow1ThisstandardisissuedunderthefixeddesignationD2925;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thistestmethodcoversmeasurementofthedeflectionasafunctionoftimeofaspecimenoffiberglasspipesupportedonaflatnon-arcedsupportasasimplebeamunderfullboreflowofwateratelevatedtemperatures.Bothglass-fiber-reinforcedthermosetting-resinpipe(RTRP)andglass-fiber-reinforcedpolymermortarpipe(RPMP)arefiberglasspipes.NOTE1—Forthepurposesofthisstandard,polymerdoesnotincludenaturalpolymers.1.2Thistestmethodcanbeusedtodeterminedeflectionatvaryingconditionsbysubstitutingothertestmedia.1.3Deflectionsobservedusingthistestmethodarerepre-sentativeonlyofpipingsupportedasasimplebeamunderfullboreflowwhichhasonediameterofpipeoverhangingateachsupport.1.4ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareprovidedforinformationpurposesonly.NOTE2—ThereisnoknownISOequivalenttothisstandard.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2C33SpecificationforConcreteAggregatesD883TerminologyRelatingtoPlasticsD1600TerminologyforAbbreviatedTermsRelatingtoPlas-ticsD3567PracticeforDeterminingDimensionsof“Fiberglass”(Glass-Fiber-ReinforcedThermosettingResin)PipeandFittingsF412TerminologyRelatingtoPlasticPipingSystems3.Terminology3.1General—DefinitionsareinaccordancewithTerminolo-giesD883andF412andabbreviationsareinaccordancewithTerminologyD1600,unlessotherwiseindicate...