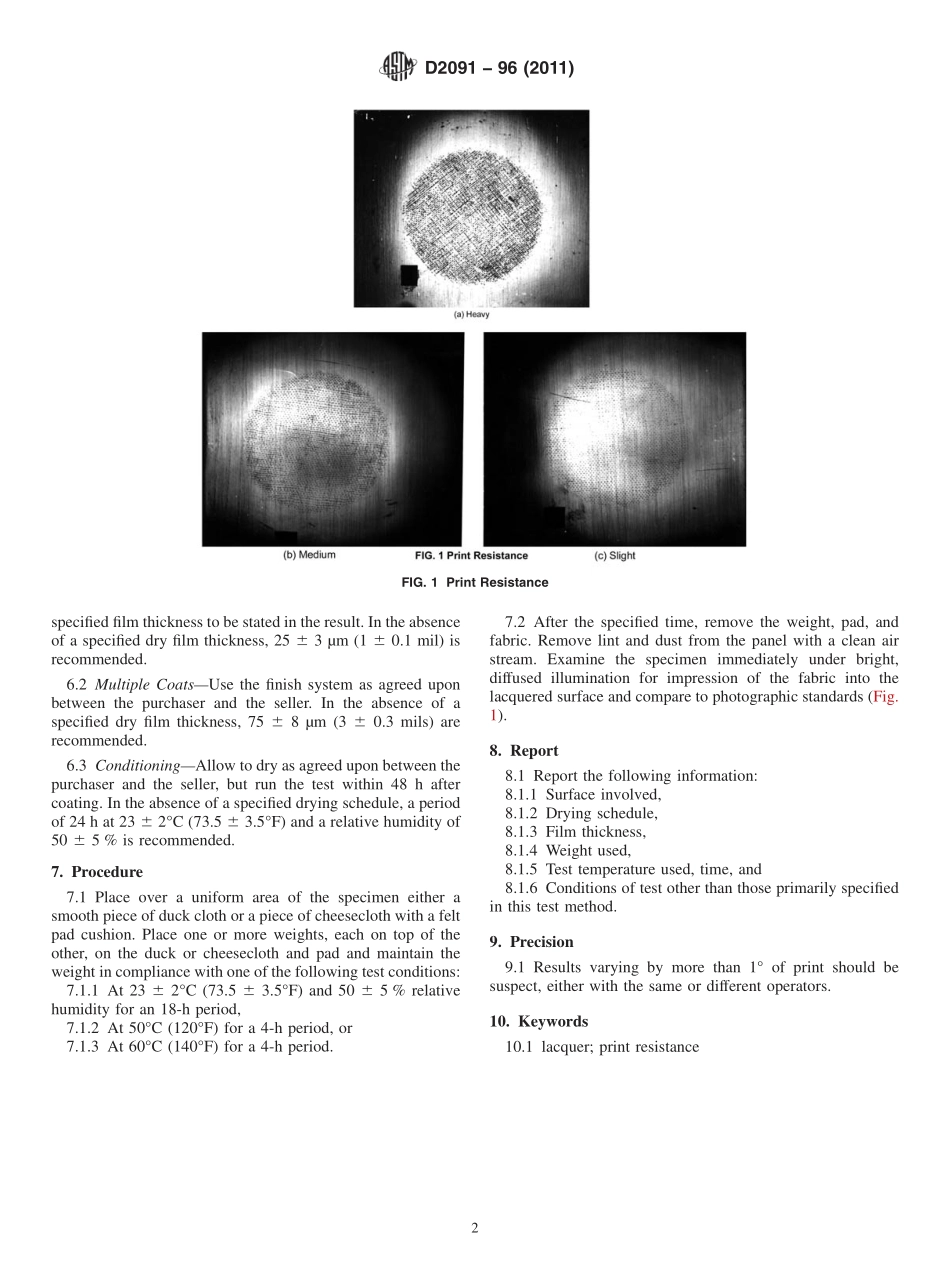

Designation:D2091−96(Reapproved2011)StandardTestMethodforPrintResistanceofLacquers1ThisstandardisissuedunderthefixeddesignationD2091;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thistestmethodcoverstheresistanceofdriedlacquerfilmstoimprinting.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D823PracticesforProducingFilmsofUniformThicknessofPaint,Varnish,andRelatedProductsonTestPanelsD1005TestMethodforMeasurementofDry-FilmThick-nessofOrganicCoatingsUsingMicrometersD1186TestMethodsforNondestructiveMeasurementofDryFilmThicknessofNonmagneticCoatingsAppliedtoaFerrousBase(Withdrawn2006)3D1400TestMethodforNondestructiveMeasurementofDryFilmThicknessofNonconductiveCoatingsAppliedtoaNonferrousMetalBase(Withdrawn2006)3D5235TestMethodforMicroscopicalMeasurementofDryFilmThicknessofCoatingsonWoodProducts2.2U.S.FederalSpecifications:4CCC-C-419(f)Cloth,Duck,Cotton,Unbleached,PliedCCC-C-440(e)Cloth,Cheesecloth,BleachedandUn-bleached3.SummaryofTestMethod3.1Aweightpressesapieceoffabricagainstthetestsurface.Thesurfaceisthenexaminedandchangesinappear-anceofthetestsurfacearereported.4.SignificanceandUse4.1Anunsatisfactoryappearancecanresultfrompressuredeformationofafilminherentlytoosoftorcontainingresidualsolvent.Thistestmethodisprimarilyusedtoevaluatetheresistanceofalacquerfinishtoprintingundertheconditionsofpackaging,shipping,andwarehousing.5.ApparatusandMaterial...