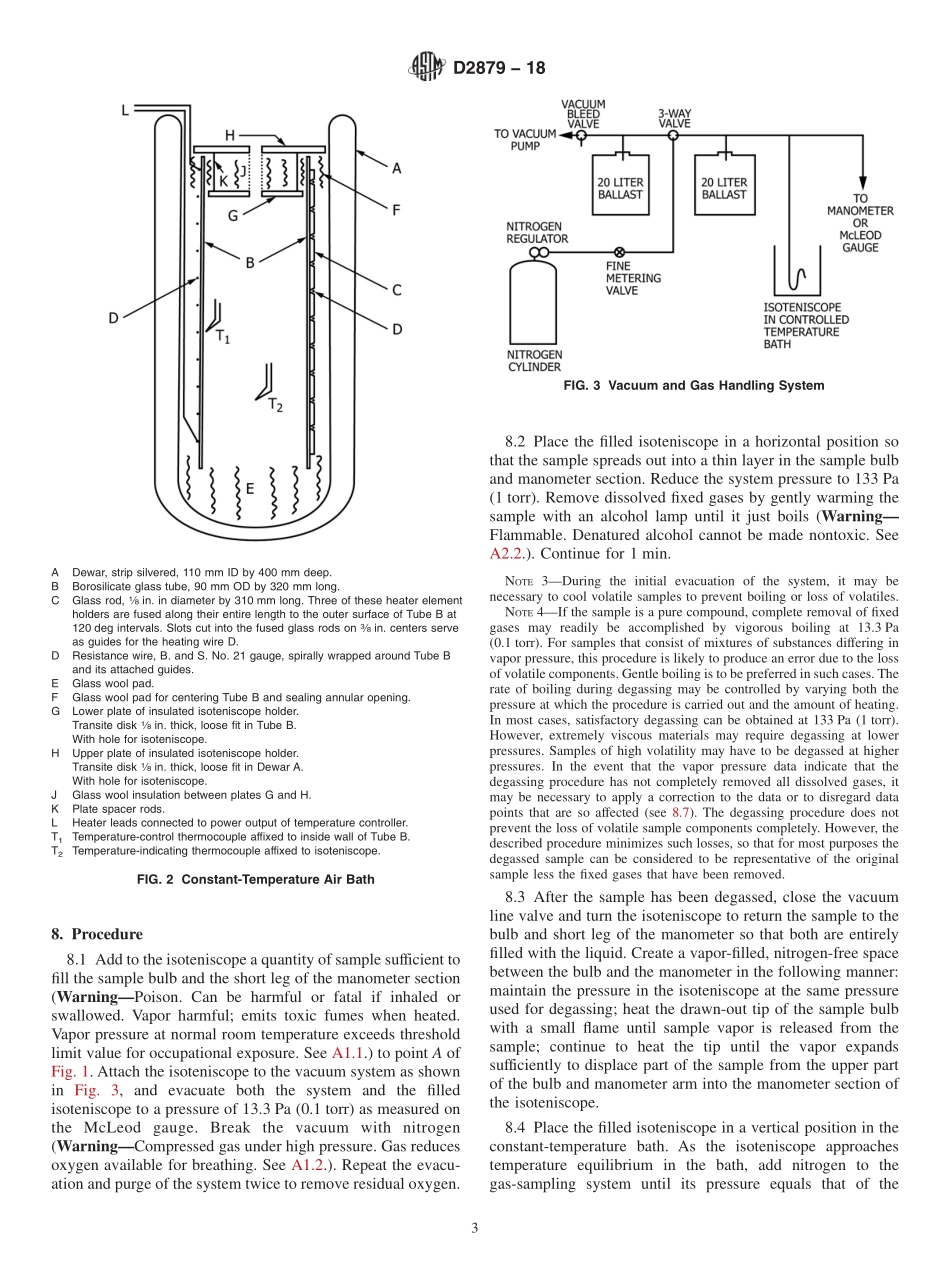

Designation:D2879−18StandardTestMethodforVaporPressure-TemperatureRelationshipandInitialDecompositionTemperatureofLiquidsbyIsoteniscope1ThisstandardisissuedunderthefixeddesignationD2879;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thistestmethodcoversthedeterminationofthevaporpressureofpureliquids,thevaporpressureexertedbymixturesinaclosedvesselat40%65%ullage,andtheinitialthermaldecompositiontemperatureofpureandmixedliquids.Itisapplicabletoliquidsthatarecompatiblewithborosilicateglassandthathaveavaporpressurebetween133Pa(1.0torr)and101.3kPa(760torr)attheselectedtesttemperatures.Thetestmethodissuitableforuseovertherangefromambientto623K.Thetemperaturerangemaybeextendedtoincludetemperaturesbelowambientprovidedasuitableconstant-temperaturebathforsuchtemperaturesisused.NOTE1—Theisoteniscopeisaconstant-volumeapparatusandresultsobtainedwithitonotherthanpureliquidsdifferfromthoseobtainedinaconstant-pressuredistillation.1.2Mostpetroleumproductsboiloverafairlywidetem-peraturerange,andthisfactshallberecognizedindiscussionoftheirvaporpressures.EvenanidealmixturefollowingRaoult’slawwillshowaprogressivedecreaseinvaporpressureasthelightercomponentisremoved,andthisisvastlyaccentuatedincomplexmixturessuchaslubricatingoilscontainingtracesofdewaxingsolvents,etc.Suchamixturemaywellexertapressureinaclosedvesselofasmuchas100timesthatcalculatedfromitsaveragecomposition,anditistheclosedvesselwhichissimulatedbytheisoteniscope.Formeasurementoftheapparentvaporpressureinopensystems,TestMethodD2878,isrecommended.1.3ThevaluesstatedinSIunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesafterSIunitsareprovidedforinformationonlyandarenotconsideredstandard.1.4WARNING—Mercuryhasbeendesignatedbyma...