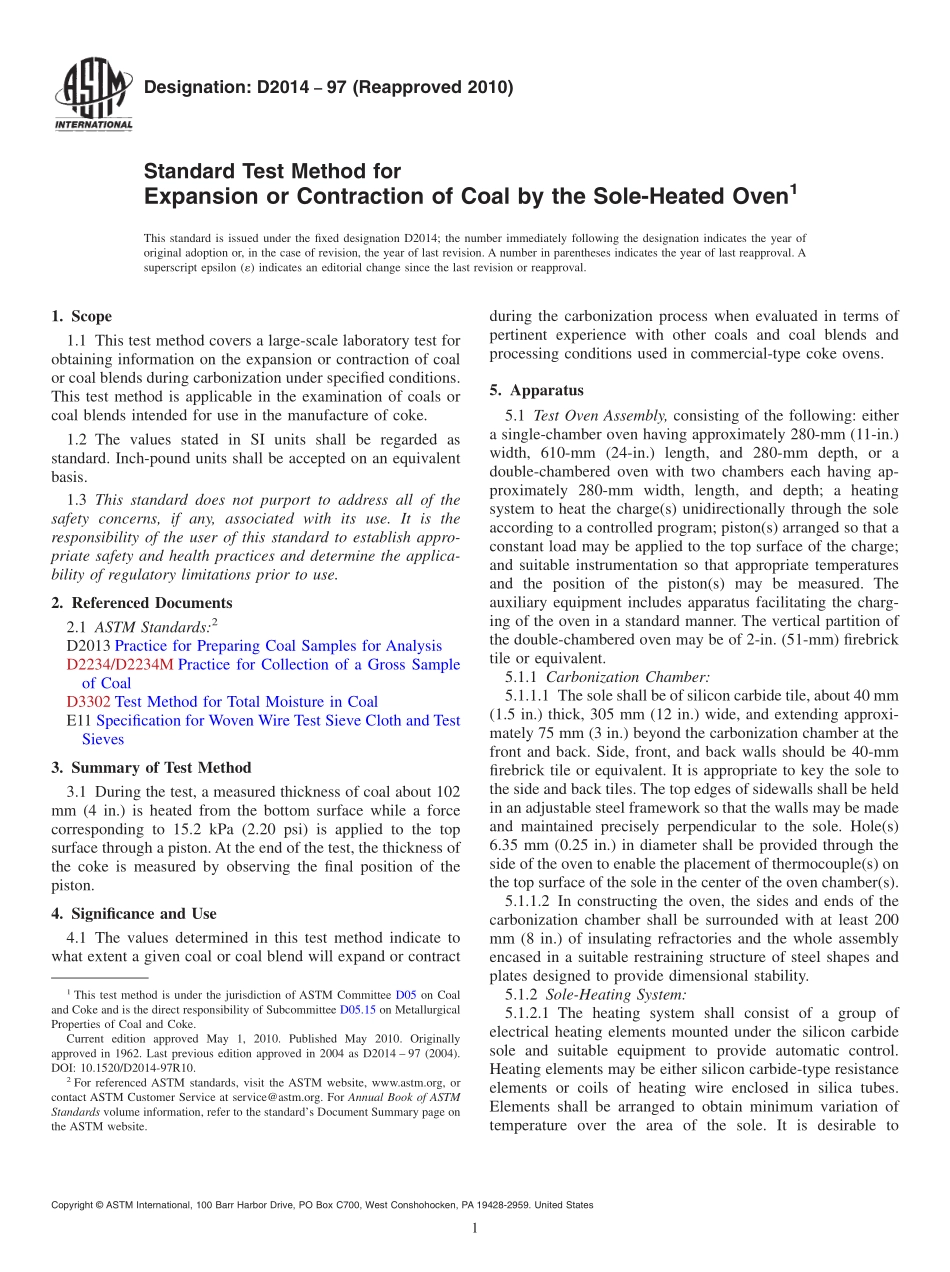

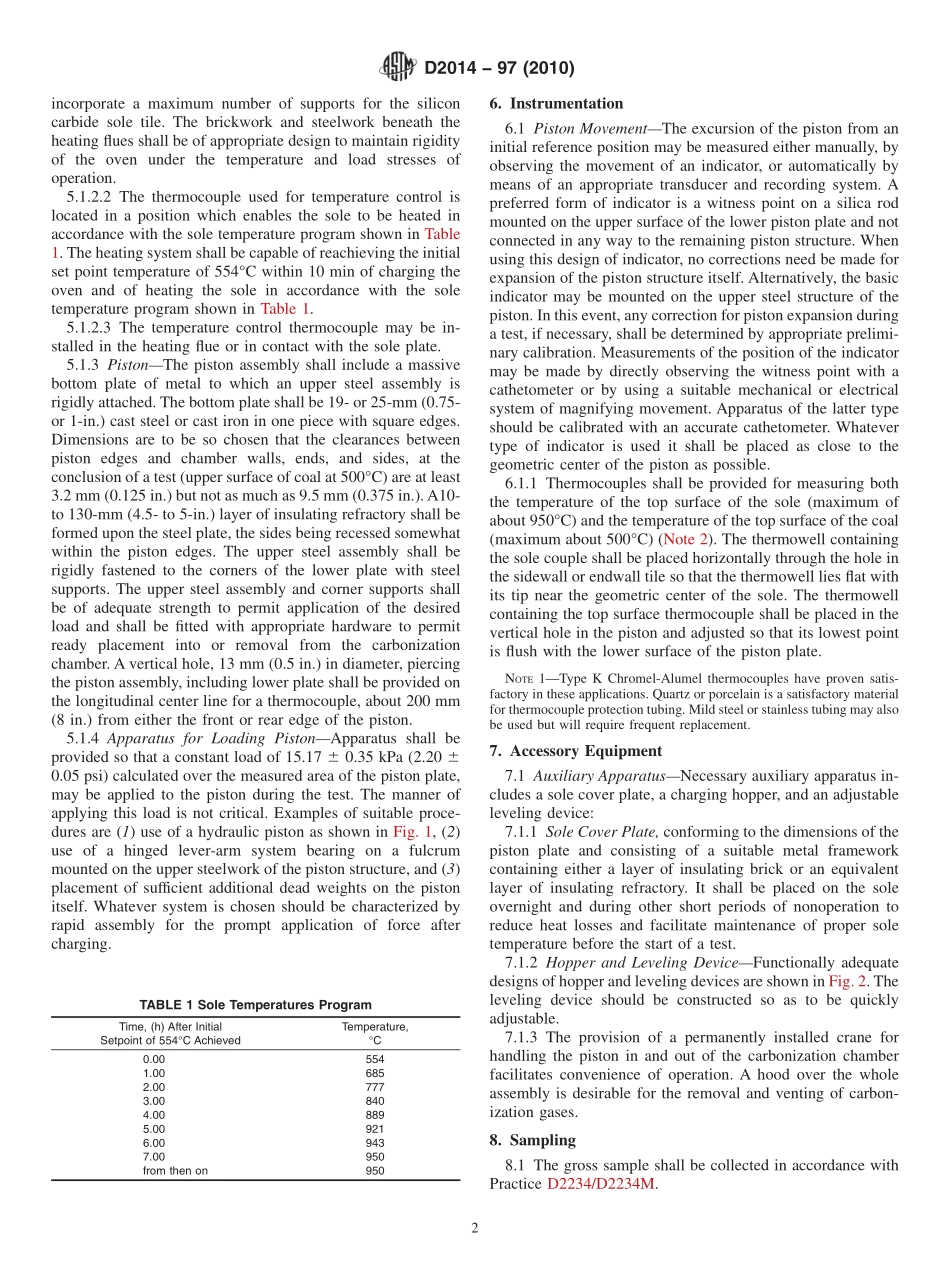

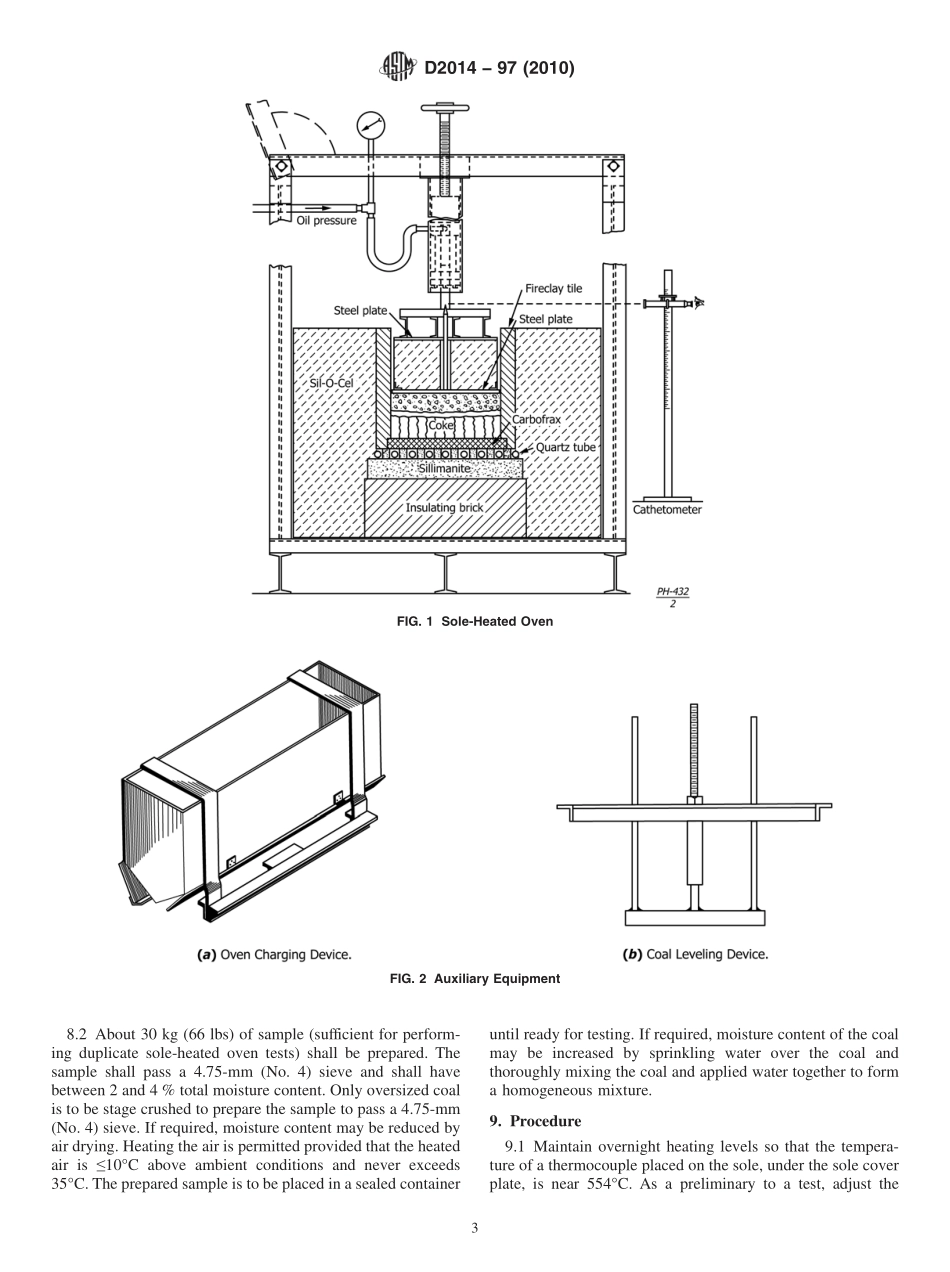

Designation:D2014−97(Reapproved2010)StandardTestMethodforExpansionorContractionofCoalbytheSole-HeatedOven1ThisstandardisissuedunderthefixeddesignationD2014;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversalarge-scalelaboratorytestforobtaininginformationontheexpansionorcontractionofcoalorcoalblendsduringcarbonizationunderspecifiedconditions.Thistestmethodisapplicableintheexaminationofcoalsorcoalblendsintendedforuseinthemanufactureofcoke.1.2ThevaluesstatedinSIunitsshallberegardedasstandard.Inch-poundunitsshallbeacceptedonanequivalentbasis.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D2013PracticeforPreparingCoalSamplesforAnalysisD2234/D2234MPracticeforCollectionofaGrossSampleofCoalD3302TestMethodforTotalMoistureinCoalE11SpecificationforWovenWireTestSieveClothandTestSieves3.SummaryofTestMethod3.1Duringthetest,ameasuredthicknessofcoalabout102mm(4in.)isheatedfromthebottomsurfacewhileaforcecorrespondingto15.2kPa(2.20psi)isappliedtothetopsurfacethroughapiston.Attheendofthetest,thethicknessofthecokeismeasuredbyobservingthefinalpositionofthepiston.4.SignificanceandUse4.1Thevaluesdeterminedinthistestmethodindicatetowhatextentagivencoalorcoalblendwillexpandorcontractduringthecarbonizationprocesswhenevaluatedintermsofpertinentexperiencewithothercoalsandcoalblendsandprocessingconditionsusedincommercial-typecokeovens.5.Apparatus5.1TestOvenAssembly,consistingofthefollowing:eitherasingle-chamberovenhavingapproximately280-mm(11-in.)width,610-mm(24-in.)length,and280-mmdepth,oradouble-chamberedovenwithtwochambersea...