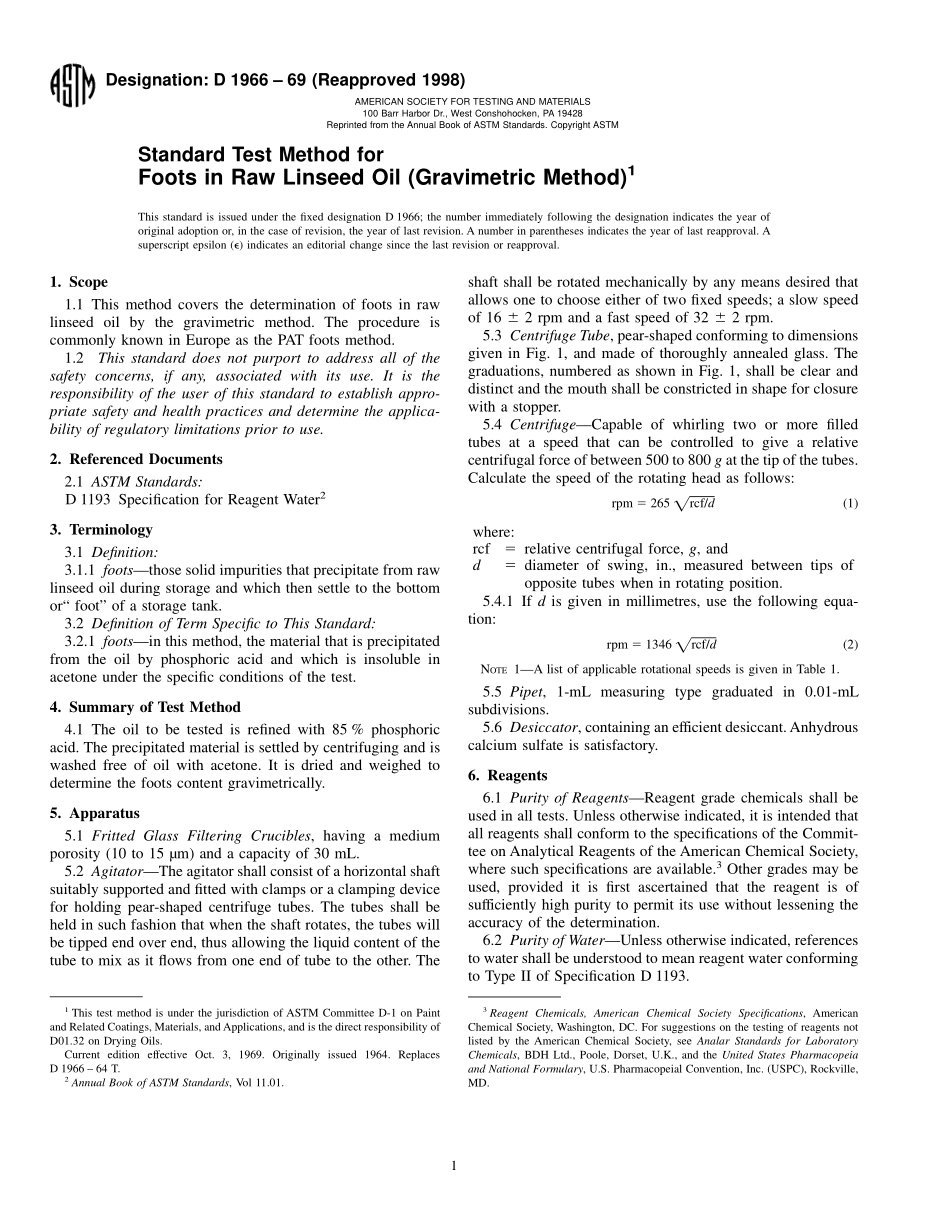

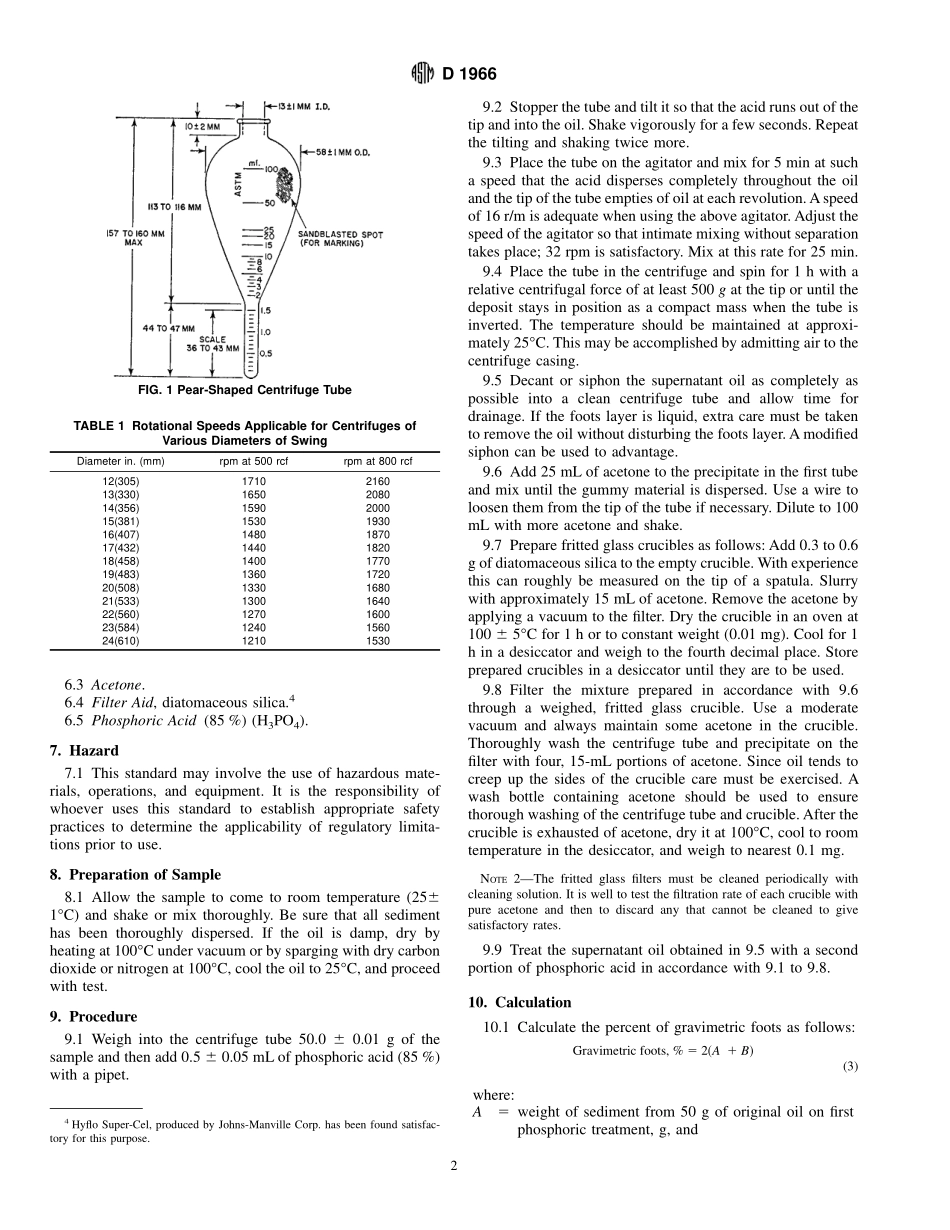

Designation:D1966–69(Reapproved1998)StandardTestMethodforFootsinRawLinseedOil(GravimetricMethod)1ThisstandardisissuedunderthefixeddesignationD1966;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thismethodcoversthedeterminationoffootsinrawlinseedoilbythegravimetricmethod.TheprocedureiscommonlyknowninEuropeasthePATfootsmethod.1.2Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:D1193SpecificationforReagentWater23.Terminology3.1Definition:3.1.1foots—thosesolidimpuritiesthatprecipitatefromrawlinseedoilduringstorageandwhichthensettletothebottomor“foot”ofastoragetank.3.2DefinitionofTermSpecifictoThisStandard:3.2.1foots—inthismethod,thematerialthatisprecipitatedfromtheoilbyphosphoricacidandwhichisinsolubleinacetoneunderthespecificconditionsofthetest.4.SummaryofTestMethod4.1Theoiltobetestedisrefinedwith85%phosphoricacid.Theprecipitatedmaterialissettledbycentrifugingandiswashedfreeofoilwithacetone.Itisdriedandweighedtodeterminethefootscontentgravimetrically.5.Apparatus5.1FrittedGlassFilteringCrucibles,havingamediumporosity(10to15µm)andacapacityof30mL.5.2Agitator—Theagitatorshallconsistofahorizontalshaftsuitablysupportedandfittedwithclampsoraclampingdeviceforholdingpear-shapedcentrifugetubes.Thetubesshallbeheldinsuchfashionthatwhentheshaftrotates,thetubeswillbetippedendoverend,thusallowingtheliquidcontentofthetubetomixasitflowsfromoneendoftubetotheother.Theshaftshallberotatedmechanicallybyanymeansdesiredthatallowsonetochooseeitheroftwofixedspeeds;aslowspeedof1662rpmandafastspeedof3262rpm.5.3CentrifugeTube,pear-shapedconformingto...