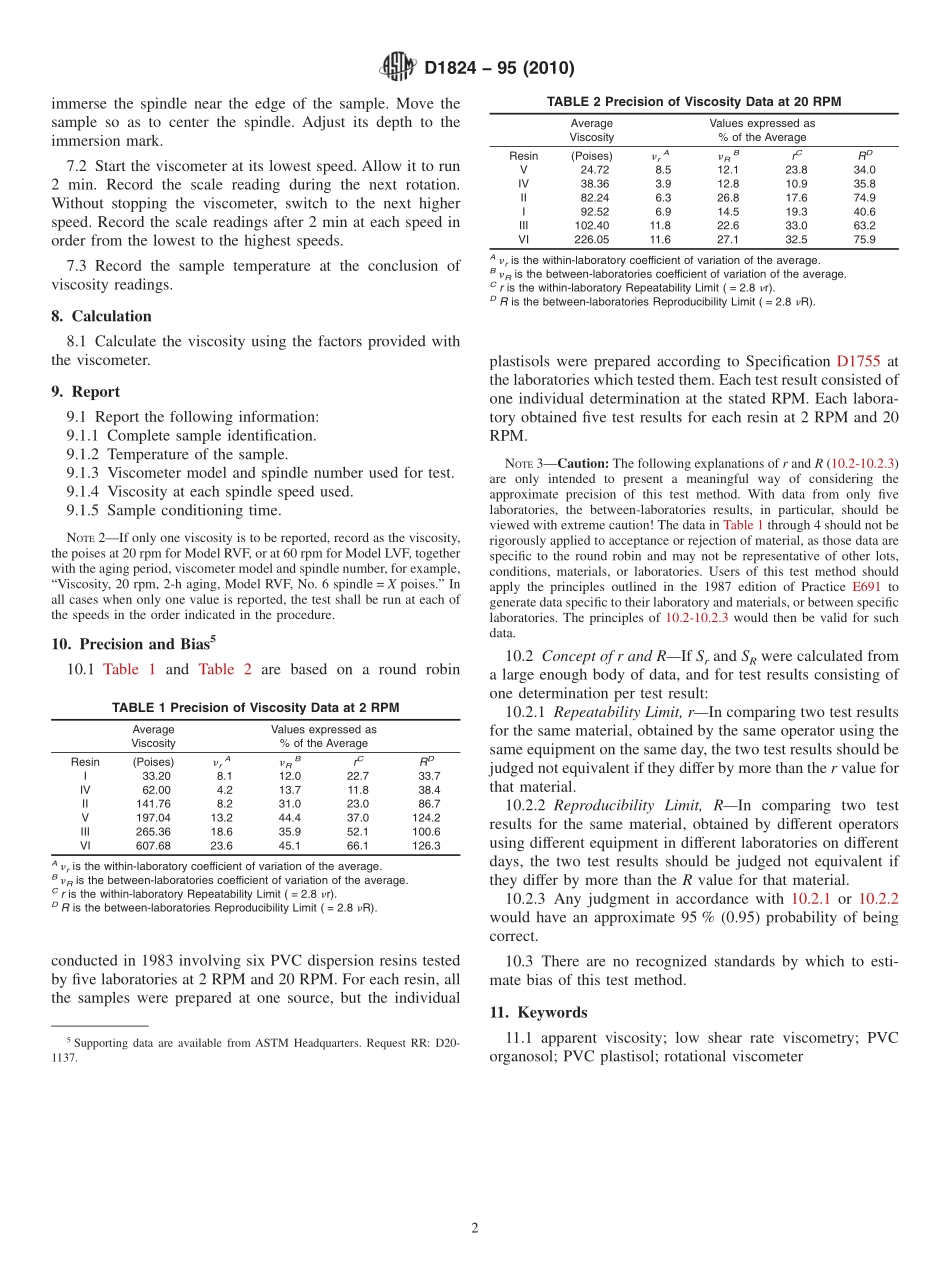

Designation:D1824−95(Reapproved2010)StandardTestMethodforApparentViscosityofPlastisolsandOrganosolsatLowShearRates1ThisstandardisissuedunderthefixeddesignationD1824;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thistestmethodcoversthemeasurementofplastisolandorganosolviscosityatlowshearrates.1.2ApparentviscosityathighshearratesiscoveredinTestMethodD1823.1.3ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.NOTE1—ThistestmethodresemblesISO3219-1977intitleonly.Thecontentissignificantlydifferent.2.ReferencedDocuments2.1ASTMStandards:2D1755SpecificationforPoly(VinylChloride)ResinsD1823TestMethodforApparentViscosityofPlastisolsandOrganosolsatHighShearRatesbyExtrusionViscometerE1SpecificationforASTMLiquid-in-GlassThermometersE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod2.2ISOStandard:ISO3219-1977:PolymersintheLiquid,Emulsified,orDispersedState—DeterminationofViscosityWithaRo-tationalViscometerWorkingataDefinedShearRate33.SummaryofTestMethod3.1Thesampleisconditionedtothepropertemperatureanditsviscosityisdetermined.4.SignificanceandUse4.1Thesuitabilityofadispersionresinforanygivenapplicationprocessisdependentuponitsviscositycharacter-istics.4.2Theviscositydefinestheflowbehaviorofaplastisolororganosolunderlowshear.Thisviscosityrelatestotheconditionsencounteredinpouring,casting,molding,anddippingprocesses.5.Apparatus5.1Viscometer.45.2SampleContainers,TinCans,orG...