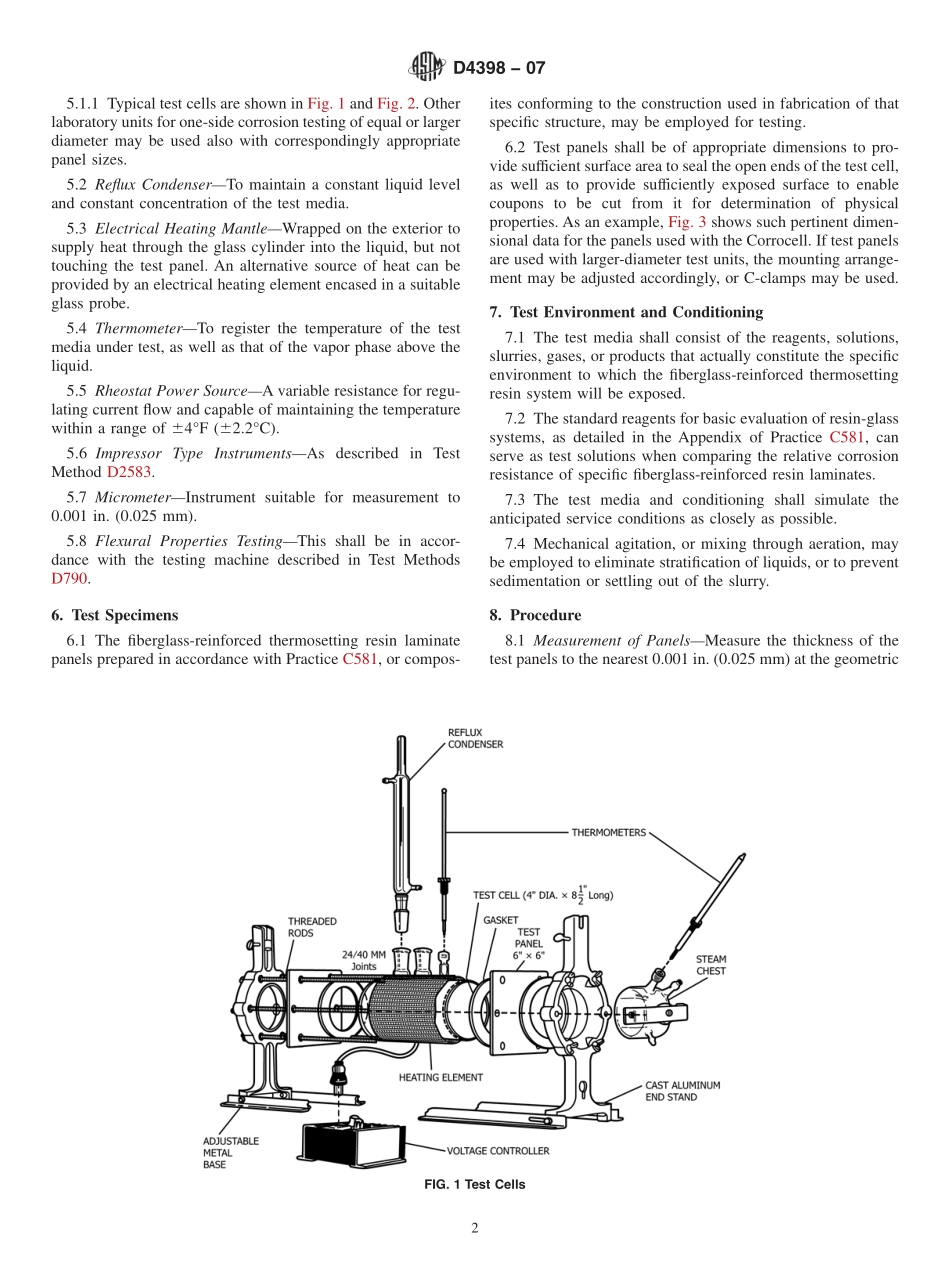

Designation:D4398−07AnAmericanNationalStandardStandardTestMethodforDeterminingtheChemicalResistanceofFiberglass-ReinforcedThermosettingResinsbyOne-SidePanelExposure1ThisstandardisissuedunderthefixeddesignationD4398;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thistestmethodisintendedforuseintheevaluationofthechemicalresistanceoffiberglass-reinforcedthermosettingresinsthataresubjectedtoone-sidepanelexposuretospecificenvironments.Ittakesintoconsiderationthecoldwalleffectsandradiationlossesofheattransferthroughthelaminatewall.1.2ThistestmethodissupplementaltoPracticeC581anddoesnotsupersedeit.NOTE1—ThereisnoknownISOequivalenttothisstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyproblems,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2C581PracticeforDeterminingChemicalResistanceofThermosettingResinsUsedinGlass-Fiber-ReinforcedStructuresIntendedforLiquidServiceD790TestMethodsforFlexuralPropertiesofUnreinforcedandReinforcedPlasticsandElectricalInsulatingMateri-alsD2583TestMethodforIndentationHardnessofRigidPlas-ticsbyMeansofaBarcolImpressor3.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1glassfiber—glassfilamentsforengineeringapplications,mostcommonly“E”typemadefromalime-aluminaborosilicateglassthatisrelativelysodafree,ofhighstrength-to-weightratiowithasizingcompatiblewiththeresinbeingused.Otherglassfibercompositionsmaybeusedbutshouldbeconsideredasvariablesforcomparisontothestandard.Glassfibersareusedcommerciallyinthereinforce-mentofrigidengineeringplasticstructures.3.1.2thermosettingresins—linear,relativelylowmolecularweightpolymerchainsthatreactduri...