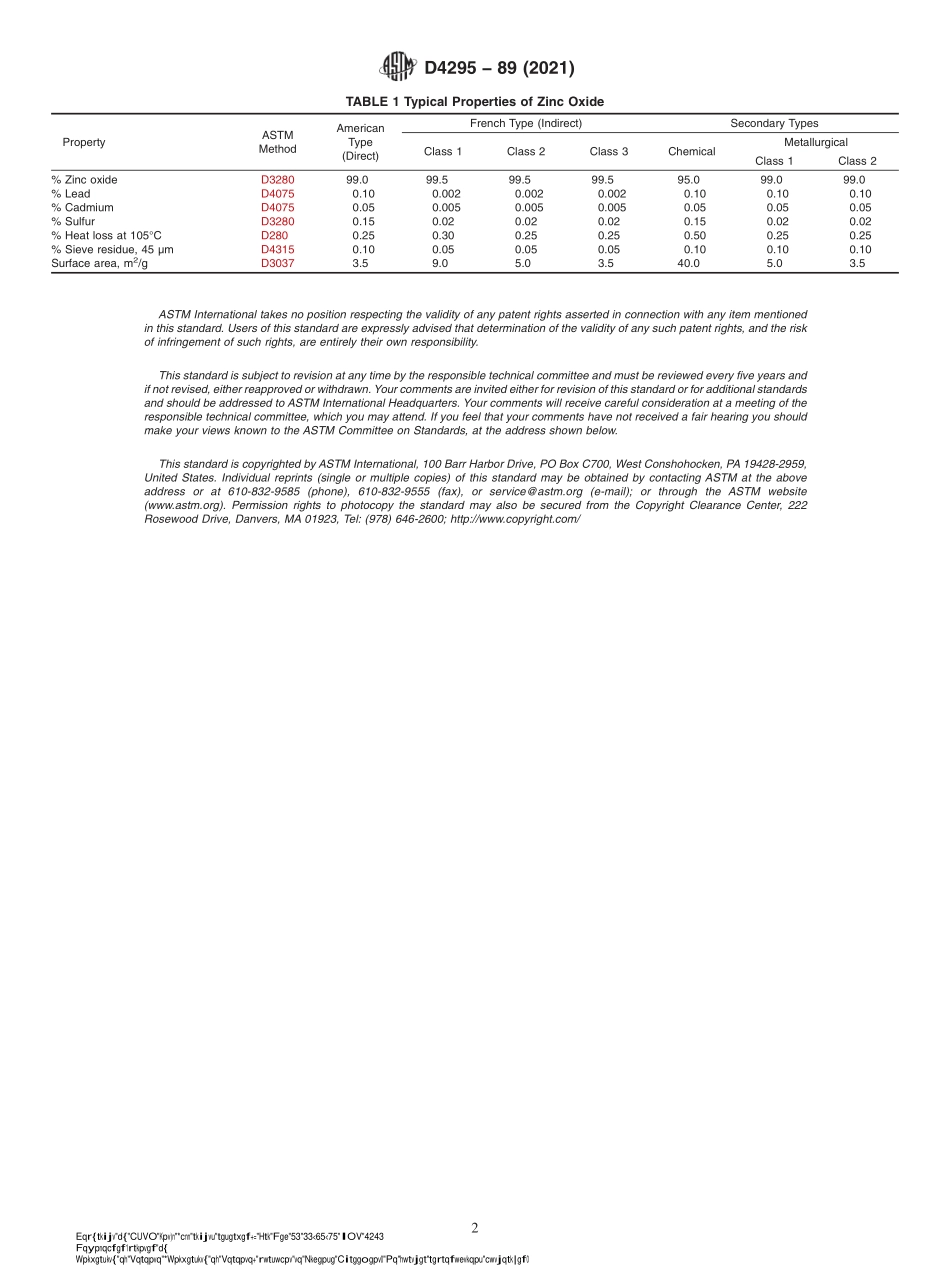

Designation:D4295−89(Reapproved2021)StandardClassificationforRubberCompoundingMaterials—ZincOxide1ThisstandardisissuedunderthefixeddesignationD4295;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisclassificationsystemcoversthecompoundingma-terialcommerciallyknownaszincoxide.Thetypesofzincoxideusedintherubberindustryarerelatedtotheproductionprocessused.Typicalchemicalandphysicalpropertiesareincluded.1.2Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D280TestMethodsforHygroscopicMoisture(andOtherMatterVolatileUndertheTestConditions)inPigmentsD3037TestMethodforCarbonBlack—SurfaceAreabyNitrogenAdsorption(Withdrawn1999)3D3280TestMethodsforAnalysisofWhiteZincPigmentsD4075TestMethodsforRubberCompoundingMaterials—FlameAtomicAbsorptionAnalysis—DeterminationofMetalsD4315TestMethodsforRubberCompoundingMaterial—ZincOxide3.SignificanceandUse3.1Zincoxideisanimportantrubbercompoundingmate-rial.Itisusedtoactivatetheorganicacceleratorstoincreasetherateofvulcanizationandtoenhancephysicalproperties.Itisalsoavulcanizingagentforhalogen-containingelastomers.4.ClassificationofZincOxidesbyTypes4.1AmericanProcessorDirectType—Whenzincoxideismanufacturedbythereductionandreoxidationofazinc-bearingmaterial,suchasazincorebyacarbonaceousfuel,itiscalledAmericanprocessordirecttype.Americanprocesszincoxideisproducedwithwidelyvaryingchemicalpropertiesandphysicalcharacteristics.Nodular-typeparticleshape,asobservedbythelightmicroscope,isgenerallypreferredforrubbercompounding.Duetowidevariationsinthematerial...