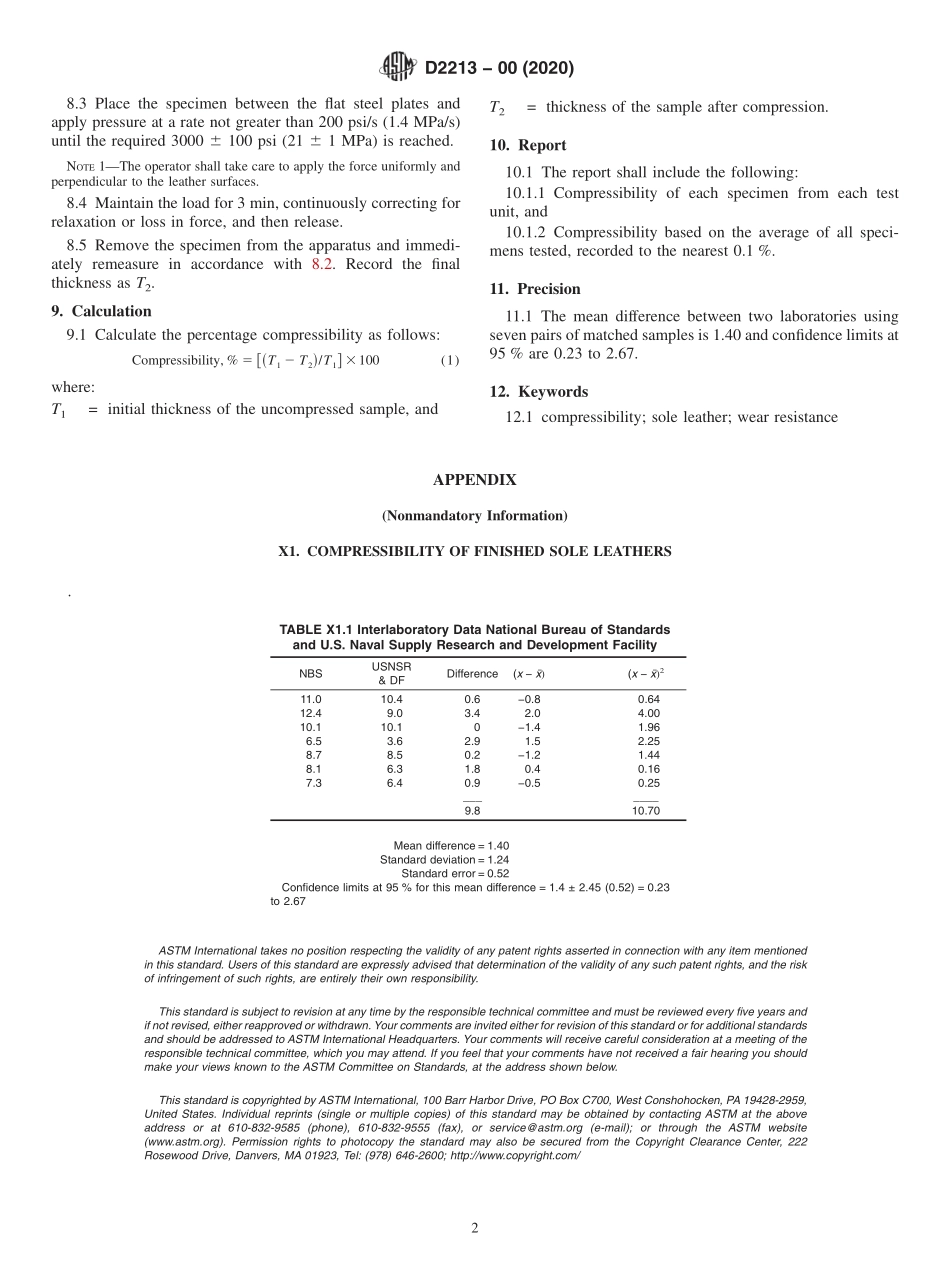

Designation:D2213−00(Reapproved2020)StandardTestMethodforCompressibilityofLeather1ThisstandardisissuedunderthefixeddesignationD2213;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thistestmethodcoversthedeterminationofthecom-pressibilityofsoleleather.Thistestmethoddoesnotapplytowetblue.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D1610PracticeforConditioningLeatherandLeatherProd-uctsforTestingD1813TestMethodforMeasuringThicknessofLeatherTestSpecimens3.Terminology3.1Definitions:3.1.1compressibility—thepercentagechangeinthicknessofaspecimenonbeingsubjectedtoaspecifiedpressureforaperiodoftime.4.SummaryofTestMethod4.1Aloadof12000lbf(53kN)or3000psi(21MPa)isappliedtoaleatherspecimen2by2-in.2(51by51-mm2).Thepercentagechangeininitialthickness,determinedbymeasur-ingthicknessesbeforeandaftercompression,representsthecompressibilityofthesample.5.SignificanceandUse5.1Compressibilityisconsideredanimportantfactorthatinfluenceswearresistanceofsoleleather.3,46.Apparatus6.1Press,5eitherh...