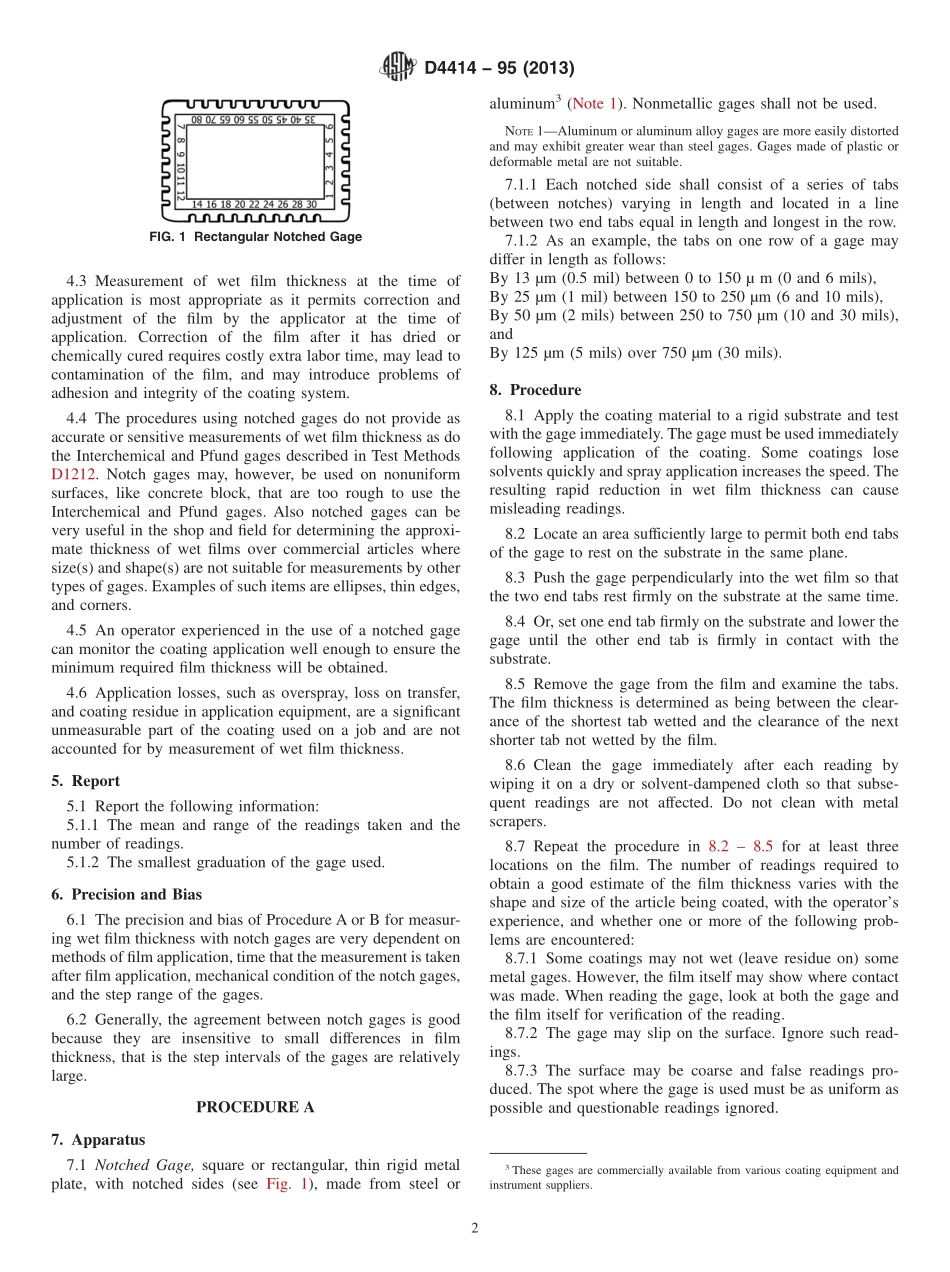

Designation:D4414−95(Reapproved2013)StandardPracticeforMeasurementofWetFilmThicknessbyNotchGages1ThisstandardisissuedunderthefixeddesignationD4414;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticedescribestheuseofthinrigidmetalnotchedgages,alsocalledsteporcombgages,inthemeasure-mentofwetfilmthicknessoforganiccoatings,suchaspaint,varnish,andlacquer.1.2Notchedgagemeasurementsareneitheraccuratenorsensitive,buttheyareusefulindeterminingapproximatewetfilmthicknessofcoatingsonarticleswheresize(s)andshape(s)prohibittheuseofthemoreprecisemethodsgiveninTestMethodsD1212.1.3Thispracticeisdividedintothefollowingtwoproce-dures:1.3.1ProcedureA—Asquareorrectangularrigidmetalgagewithnotchedsidesisusedtomeasurewetfilmthick-nessesrangingfrom3to2000µm(0.5to80mils1).Suchagageisapplicabletocoatingsonflatsubstratesandtocoatingsonarticlesofvarioussizesandcomplexshapeswhereitispossibletogettheendtabsofthegagetorestinthesameplaneonthesubstrate.1.3.2ProcedureB—Acircularthinrigidmetalnotchedgageisusedtomeasurewetfilmthicknessesrangingfrom25to2500µm(1to100mils).Suchagageisapplicabletocoatingsonflatsubstratesandtocoatingsonobjectsofvarioussizesandcomplexshapes.1.4ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D1212TestMethodsforMeasurementofWetFilmThick-nessofOrganicCoatings3.SummaryofPractice3.1Thematerialisappliedtothearticlestobecoatedandthewetfilmthicknessmeasuredwithanotchedgage.3.2ProcedureA—Asquareorrectangularthinrigidmeta...