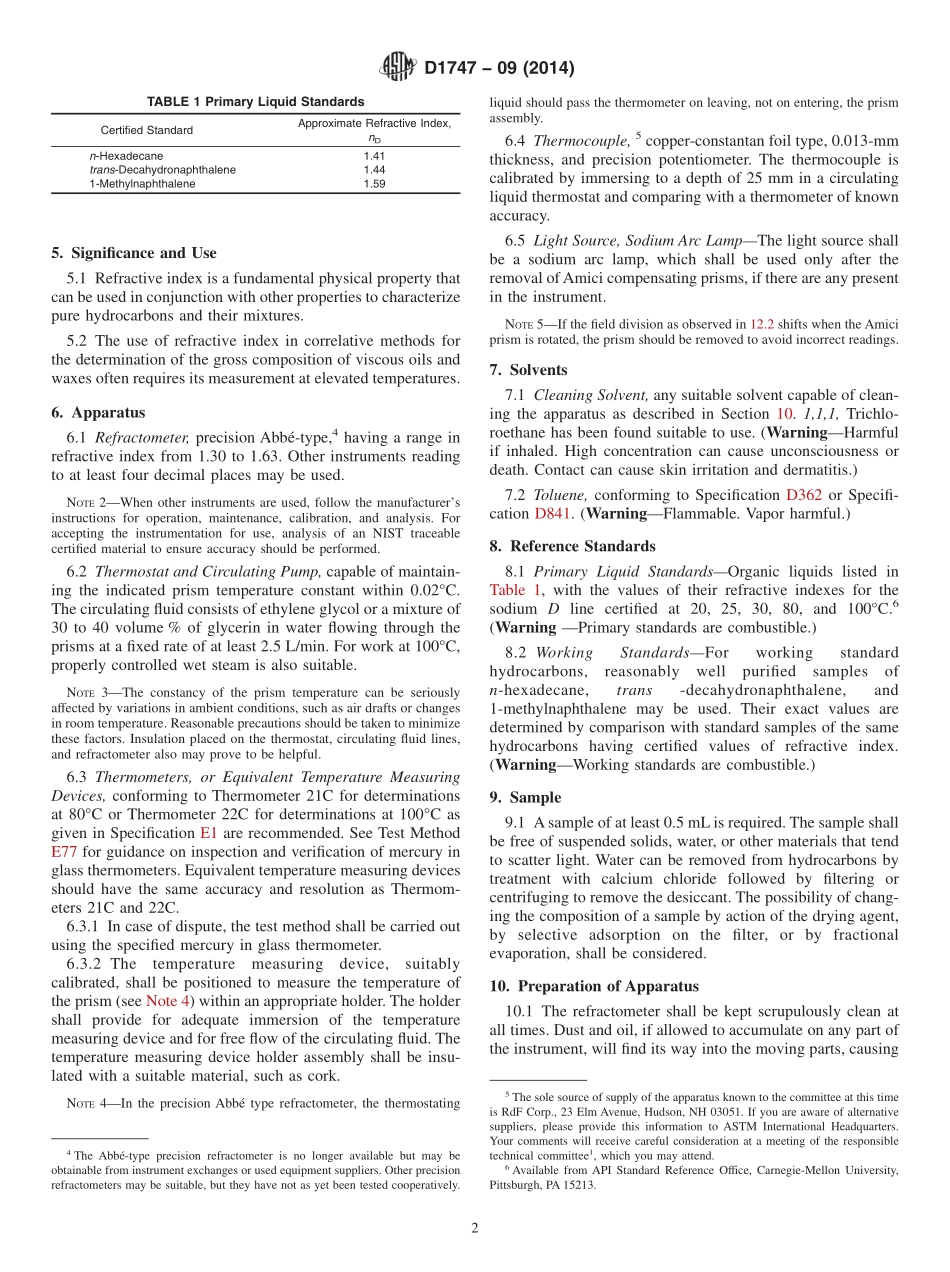

Designation:D1747−09(Reapproved2014)StandardTestMethodforRefractiveIndexofViscousMaterials1ThisstandardisissuedunderthefixeddesignationD1747;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thistestmethodcoversthemeasurementofrefractiveindexes,accuratetotwounitsinthefourthdecimalplace,oftransparentandlight-coloredviscoushydrocarbonliquidsandmeltedsolidsthathaverefractiveindexesintherangebetween1.33and1.60,andattemperaturesfrom80to100°C.Tem-peratureslowerthan80°Ccanbeusedprovidedthatthemeltingpointofthesampleisatleast10°Cbelowthetesttemperature.1.2Thistestmethodisnotapplicable,withintheaccuracystated,toliquidshavingcolorsdarkerthanASTMColorNo.4,ASTMcolorasdeterminedbyTestMethodD1500,toliquidswhichsmokeorvaporizereadilyatthetesttemperature,ortosolidsmeltingwithin10°Cofthetesttemperature.NOTE1—Theinstrumentcanbesuccessfullyusedforrefractiveindicesabove1.60;butsincecertifiedliquidstandardsforrangesabove1.60arenotyetavailable,theaccuracyofmeasurementundertheseconditionshasnotbeenevaluated.1.3ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.4Warning—MercuryhasbeendesignatedbyEPAandmanystateagenciesasahazardousmaterialthatcancausecentralnervoussystem,kidney,andliverdamage.Mercury,oritsvapor,maybehazardoustohealthandcorrosivetomaterials.Cautionshouldbetakenwhenhandlingmercuryandmercury-containingproducts.SeetheapplicableproductMa-terialSafetyDataSheet(MSDS)fordetailsandEPA’swebsite(http://www.epa.gov/mercury/faq.htm)foradditionalinforma-tion.Usersshouldbeawarethatsellingmercuryormercury-containingproducts,orboth,inyourstatemaybeprohibitedbystatelaw.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedw...