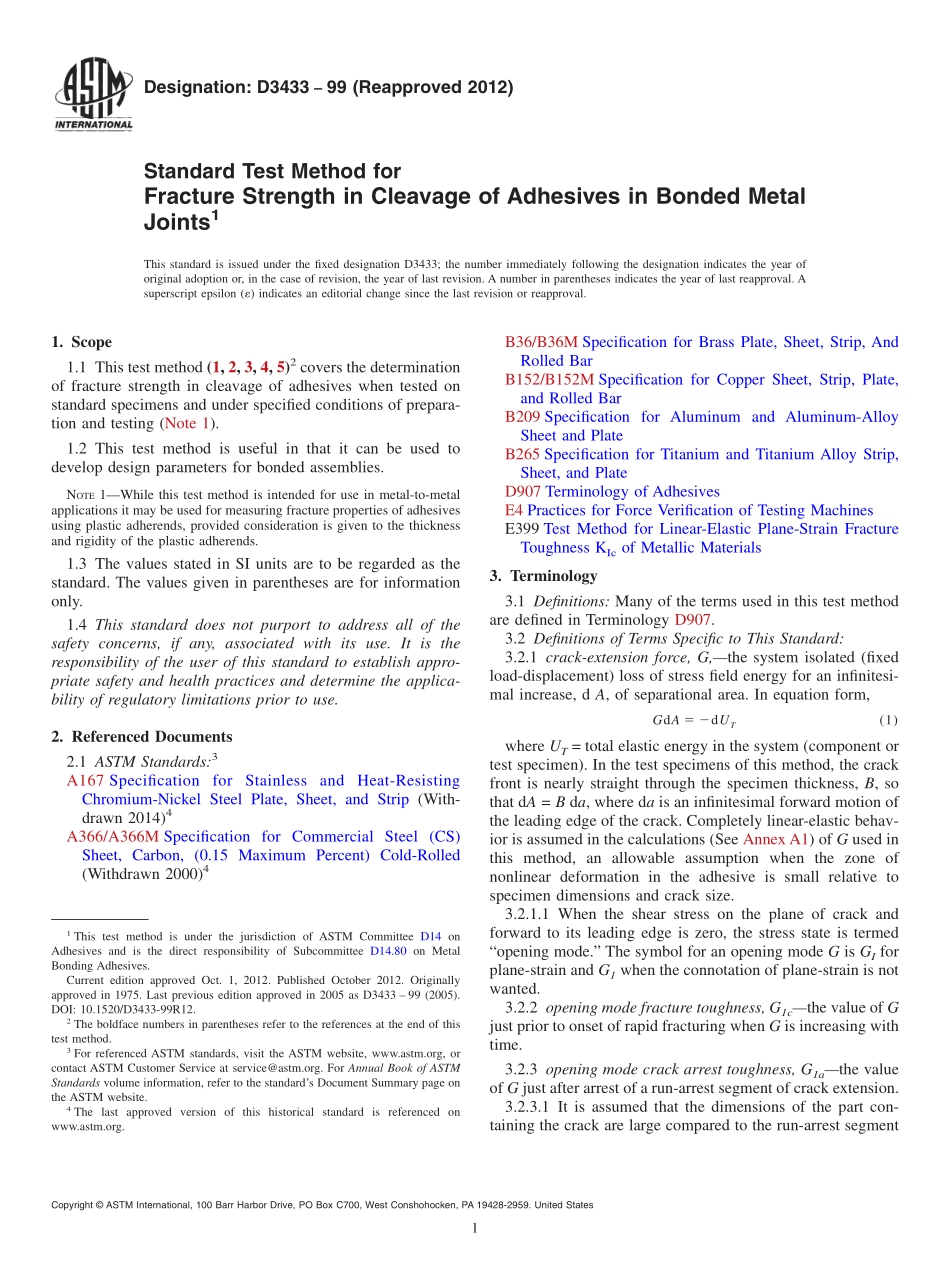

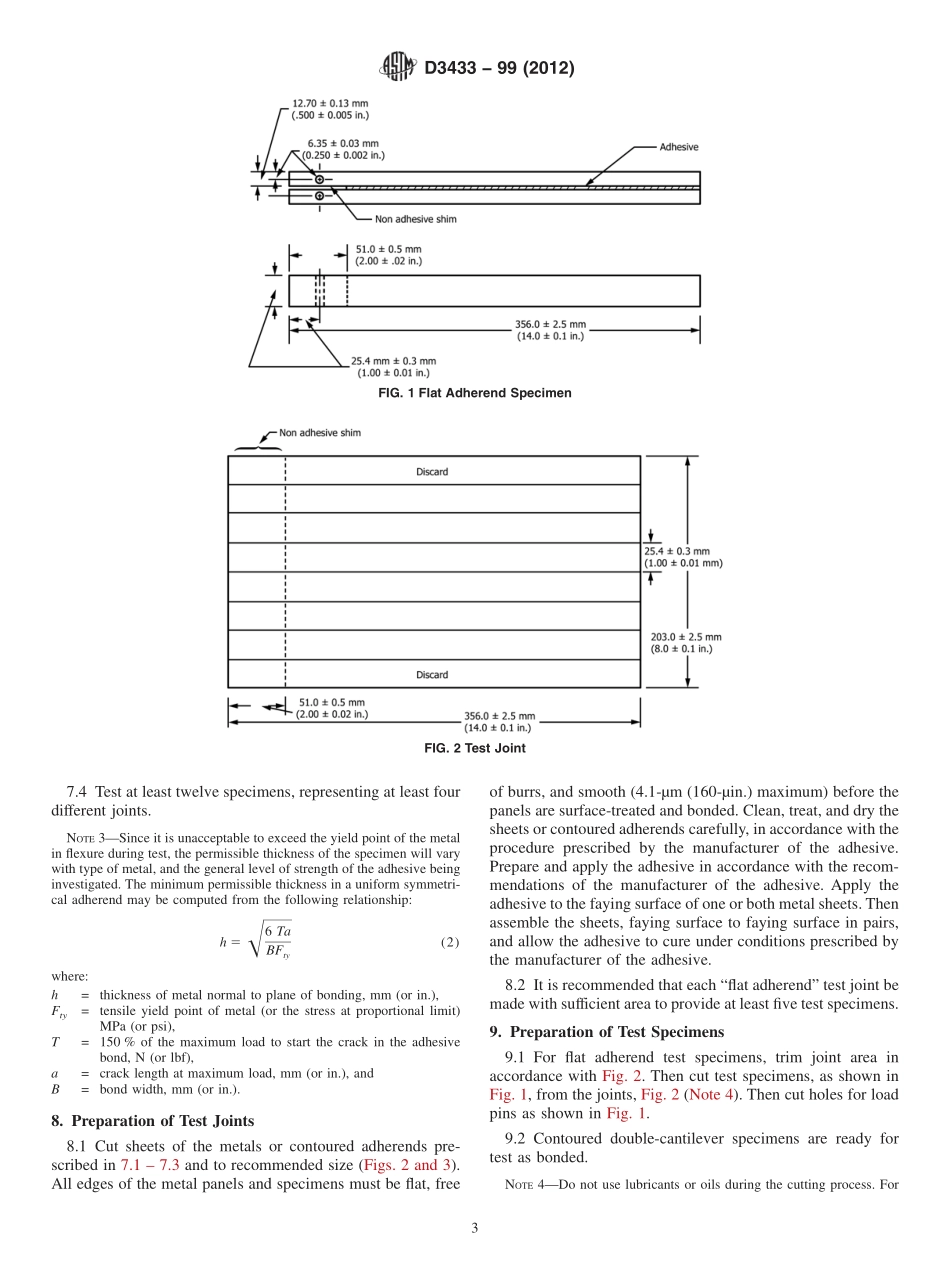

Designation:D3433−99(Reapproved2012)StandardTestMethodforFractureStrengthinCleavageofAdhesivesinBondedMetalJoints1ThisstandardisissuedunderthefixeddesignationD3433;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethod(1,2,3,4,5)2coversthedeterminationoffracturestrengthincleavageofadhesiveswhentestedonstandardspecimensandunderspecifiedconditionsofprepara-tionandtesting(Note1).1.2Thistestmethodisusefulinthatitcanbeusedtodevelopdesignparametersforbondedassemblies.NOTE1—Whilethistestmethodisintendedforuseinmetal-to-metalapplicationsitmaybeusedformeasuringfracturepropertiesofadhesivesusingplasticadherends,providedconsiderationisgiventothethicknessandrigidityoftheplasticadherends.1.3ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:3A167SpecificationforStainlessandHeat-ResistingChromium-NickelSteelPlate,Sheet,andStrip(With-drawn2014)4A366/A366MSpecificationforCommercialSteel(CS)Sheet,Carbon,(0.15MaximumPercent)Cold-Rolled(Withdrawn2000)4B36/B36MSpecificationforBrassPlate,Sheet,Strip,AndRolledBarB152/B152MSpecificationforCopperSheet,Strip,Plate,andRolledBarB209SpecificationforAluminumandAluminum-AlloySheetandPlateB265SpecificationforTitaniumandTitaniumAlloyStrip,Sheet,andPlateD907TerminologyofAdhesivesE4PracticesforForceVerificationofTestingMachinesE399TestMethodforLinear-ElasticPlane-StrainFractureToughnessKIcofMetallicMaterials3.Terminology3.1Definitions:ManyofthetermsusedinthistestmethodaredefinedinTerminologyD907.3...