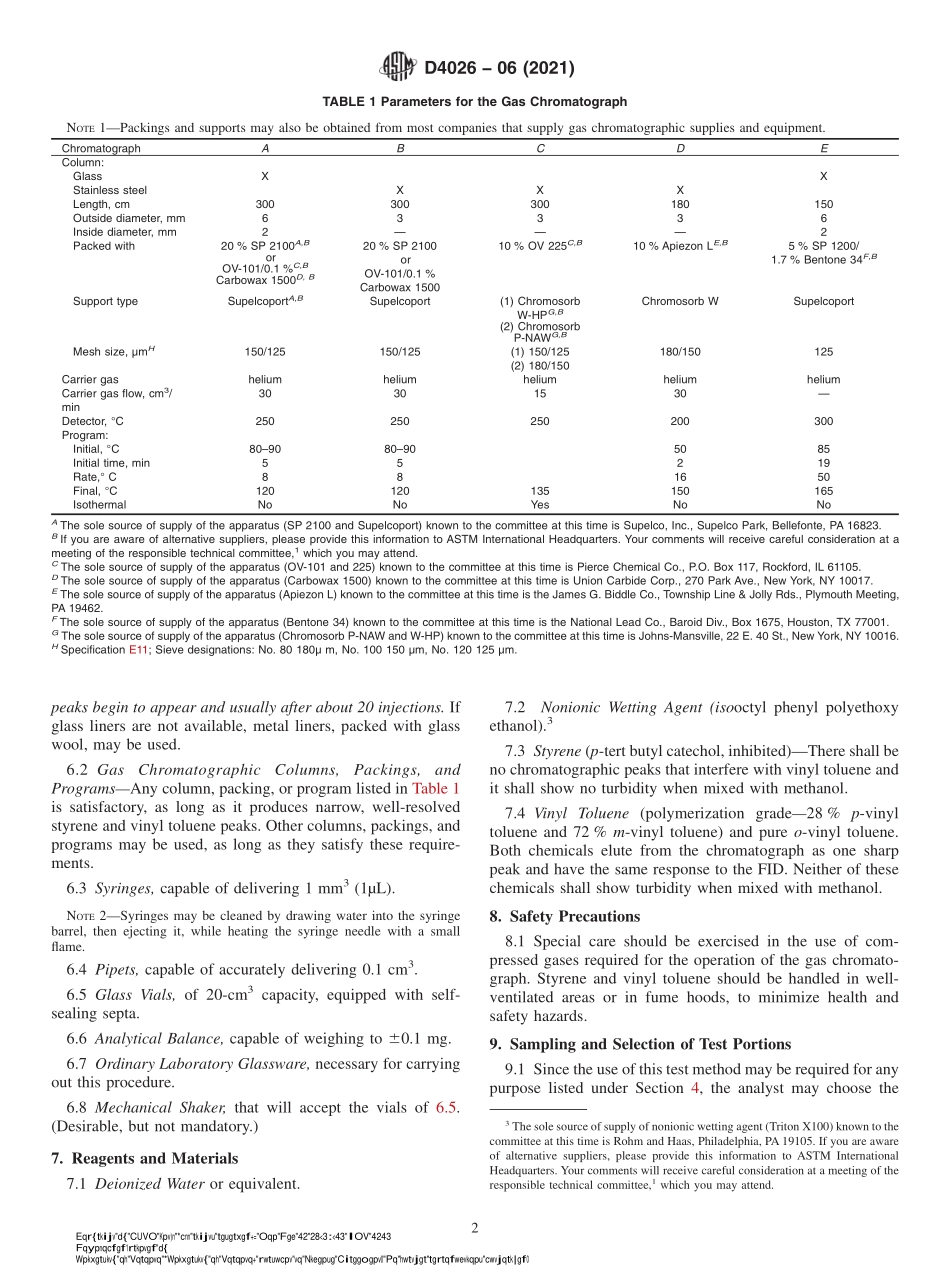

Designation:D4026−06(Reapproved2021)StandardTestMethodforRubberLatex—Styrene-ButadieneCopolymer—DeterminationofResidualStyrene1ThisstandardisissuedunderthefixeddesignationD4026;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationofthere-sidualstyrenecontentofstyrenebutadiene(SBR)latex.Thistestmethodisbasedupondirectinjectionofadilutedlatexintoagaschromatograph.Theamountofresidualstyreneiscalculatedusinganinternalstandardtechnique.1.2Therangeofresidualstyrenecoveredisapproximately100to3000mg/kg(ppm)withalowerdetectionlimitofapproximately50mg/kg(ppm).1.3ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.(Forspecificsafetystatements,seeSection8.)1.5Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D4483PracticeforEvaluatingPrecisionforTestMethodStandardsintheRubberandCarbonBlackManufacturingIndustriesE11SpecificationforWovenWireTestSieveClothandTestSievesE260PracticeforPackedColumnGasChromatographyE355PracticeforGasChromatographyTermsandRelation-ships3.SummaryofTestMethod3.1Asampleoflatexismixedwithawettingagentandaninternalstandardofvinyltoluene.Itistheninjectedintoagaschromatographequippedwithaflameionizationdetector.Theamountofresidualstyreneisdet...