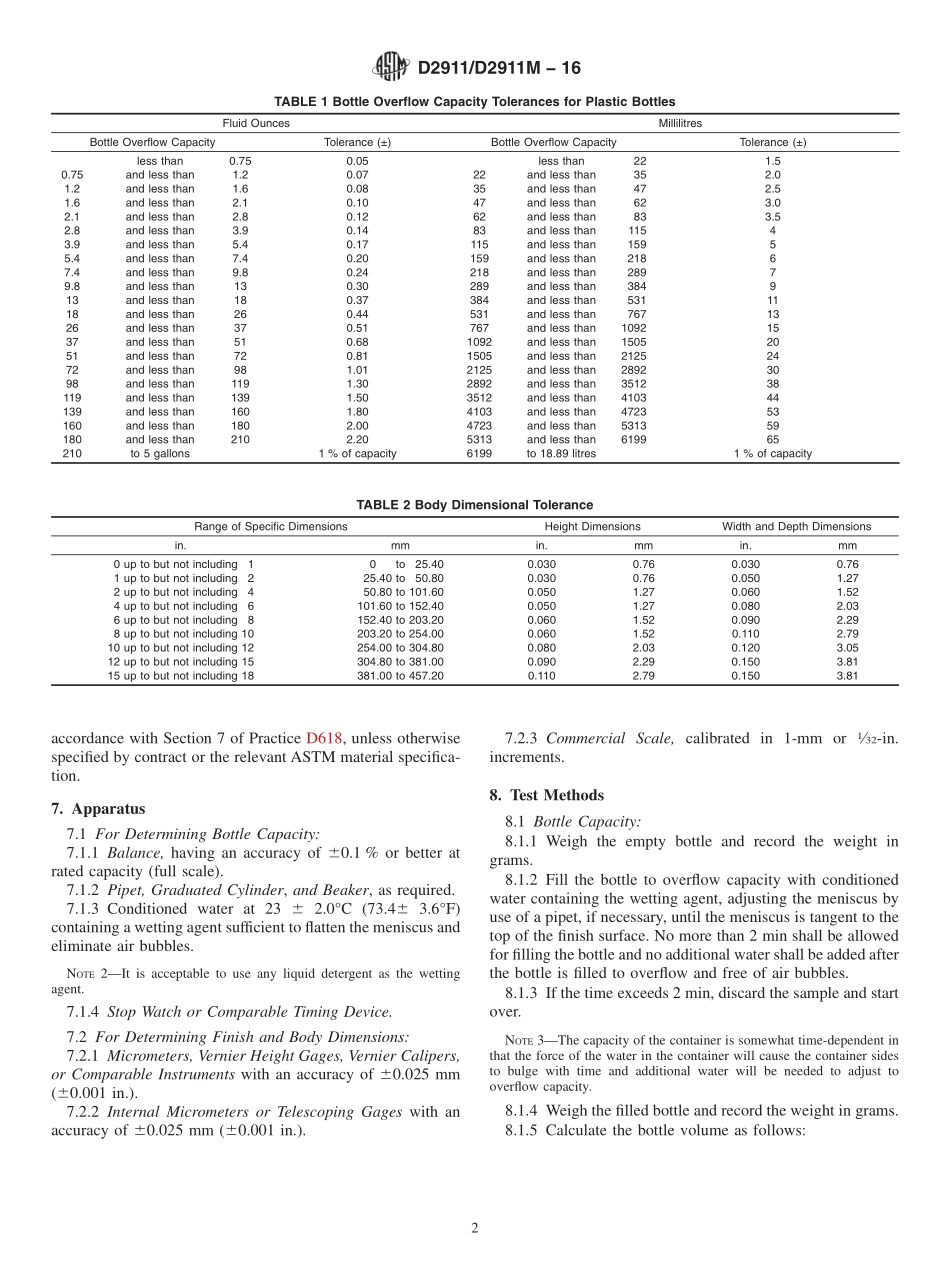

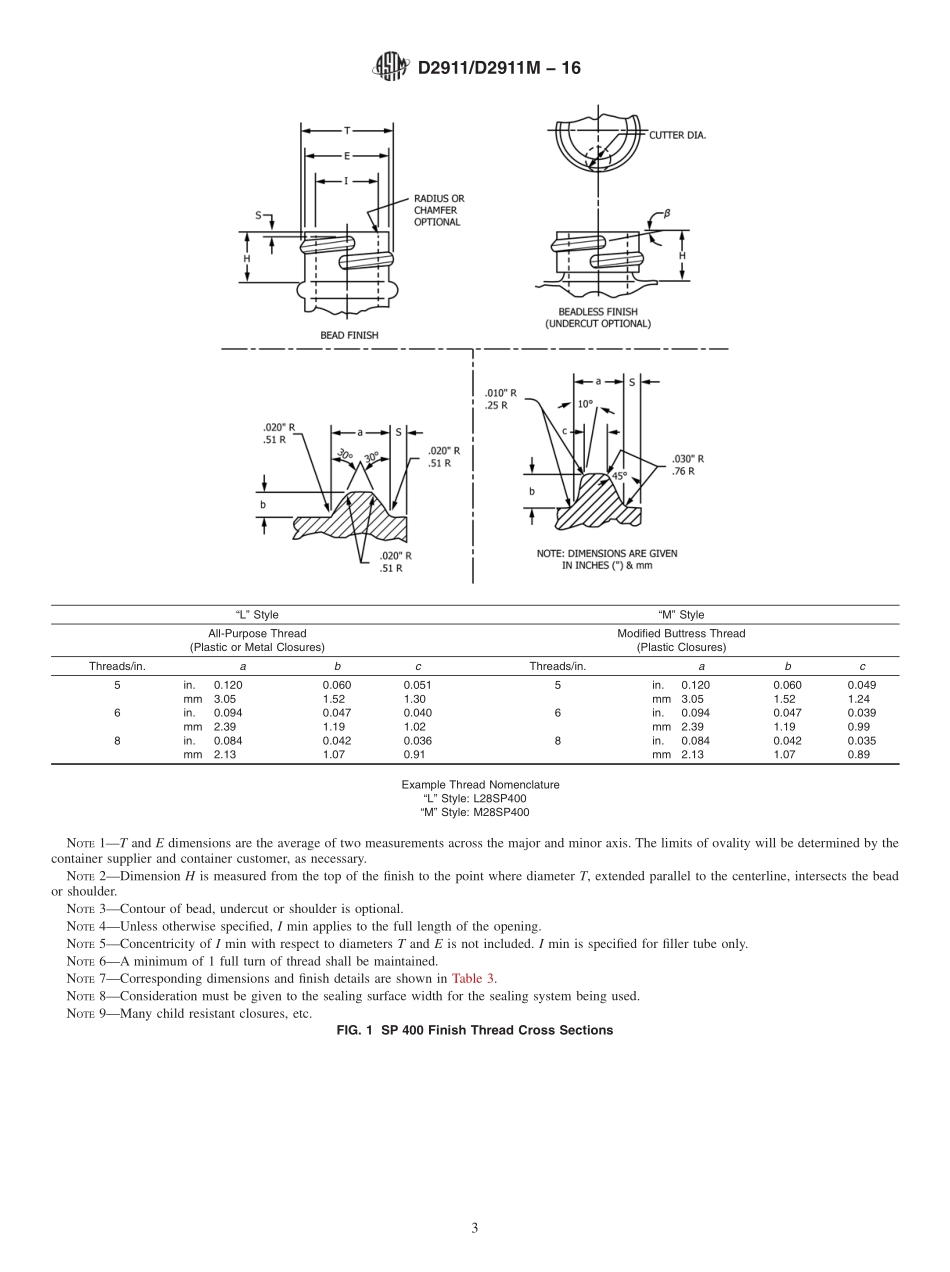

Designation:D2911/D2911M−16StandardSpecificationforDimensionsandTolerancesforPlasticBottles1ThisstandardisissuedunderthefixeddesignationD2911/D2911M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationcoversthethreadconfigurationanddimensionsforfinishesforplasticbottleswithscrew-typeclosures,havingamaximumcapacityof18.9L(5gal)andamaximumbottledimensionof305mm(12in.).Includedaretolerancesforbottlecapacityandbodydimensions.1.2Units—ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.3Thefollowingprecautionarycaveatpertainsonlytothetestmethodsportion,Section8ofthisspecification.Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimita-tionspriortouse.NOTE1—ThereisnoknownISOequivalenttothisstandard.2.ReferencedDocuments2.1ASTMStandards:2D618PracticeforConditioningPlasticsforTestingD1898PracticeforSamplingofPlastics(Withdrawn1998)33.Terminology3.1Definitions:3.1.1bottlefinish—theconfigurationoftheneckoropeningofthebottlewhichservestoengagespecificpartsoftheclosureinordertosecurelyattachittothebottle.3.1.2bottleheight—themaximumdimensionofabottleinaplaneperpendiculartothebottlebasewhenthebottleissettinginitsnormaluprightposition.3.1.3bottlethickness—thesmallerdimensioninaplaneparalleltothebottlebase.3.1.4bottlewidth—thelargerdimensioninaplaneparalleltothebottlebase.4.DimensionsandRecommendedVariations4.1RecommendedVariationsinOverflowCapacity—Inoverflowcapacityr...