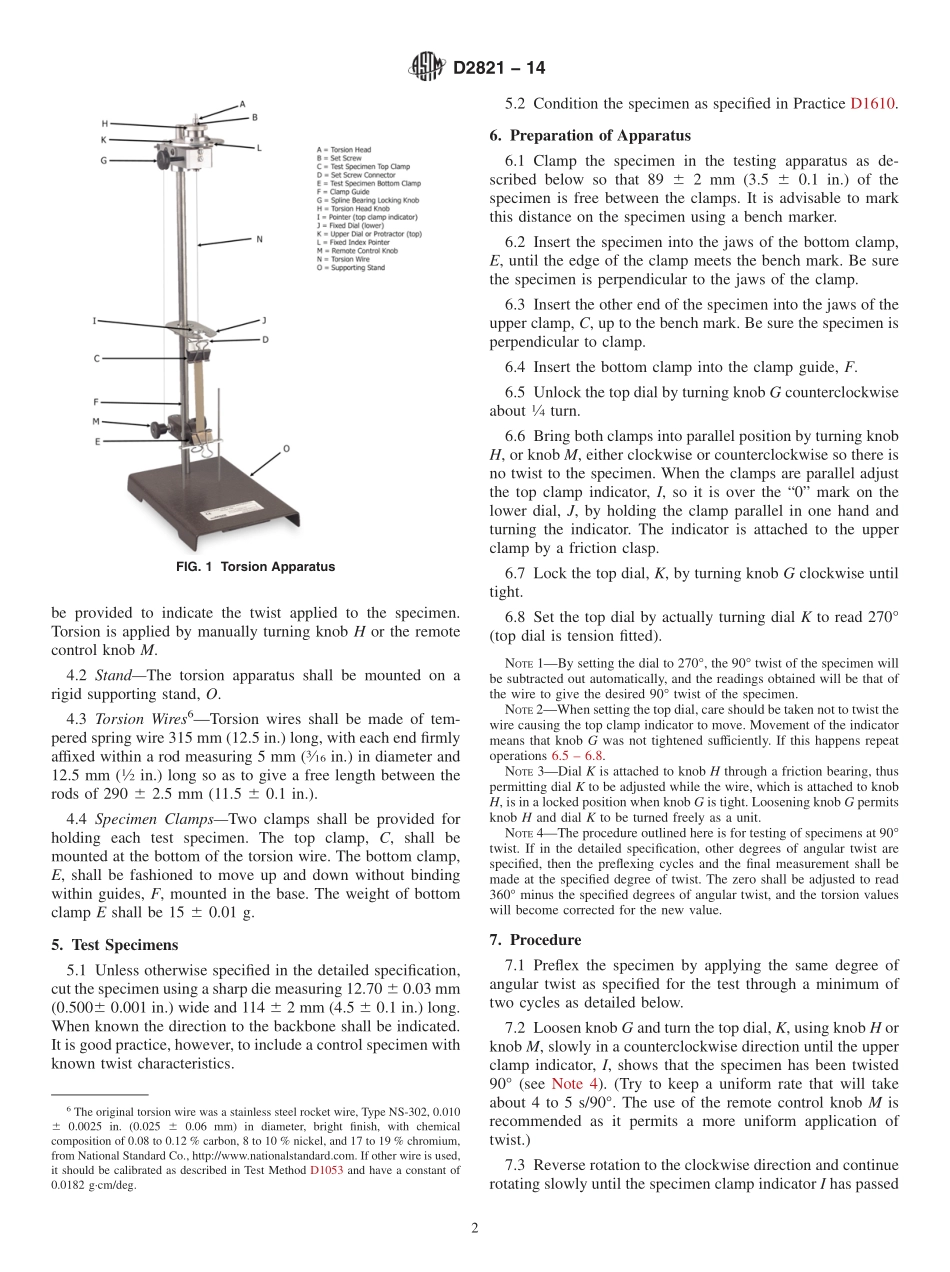

Designation:D2821−14StandardTestMethodforMeasuringtheRelativeStiffnessofLeatherbyMeansofaTorsionalWireApparatus1ThisstandardisissuedunderthefixeddesignationD2821;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thistestmethoddescribestheuseofatorsionalapparatusformeasuringtherelativestiffnessofglovingleath-ers.Thistestmethoddoesnotapplytowetblue.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesshowninparenthesesareprovidedforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D1053TestMethodsforRubberProperty—StiffeningatLowTemperatures:FlexiblePolymersandCoatedFabricsD1610PracticeforConditioningLeatherandLeatherProd-uctsforTesting3.SignificanceandUse3.1Thistestmethodisdesignedtomeasuretheapparenttorsionalmodulus3ofaleatherspecimen.Experiencehasshownthatthetorsionmodulusofleatherisdirectlyrelatedtothecharacteristicknownasstiffnesswhenfeltinaglove.44.Apparatus4.1TorsionApparatus5—Thetorsionalapparatus,Fig.1,shallconsistofatorsionhead,A,capableofbeingturnedthroughacompletecircleinaplanenormaltothetorsionwire,N.Thetorsionheadisequippedwithanupperdialorprotractor,K,graduatedfrom0to360°inincrementsnotgreaterthan5°,andafixedindexpointer,L.Theprotractorisattachedtothetorsionheadbymeansofafrictionbearingtopermitmovementforadjustingthezeropoint.ThetopofthetorsionwireisattachedtothetorsionheadatknobHbysetscrewBandpassesthroughthecenterofalooselyfittingsleevegrippedbythefrictionbearing.Thetorsionheadsupportcarriesasplitbearingwh...