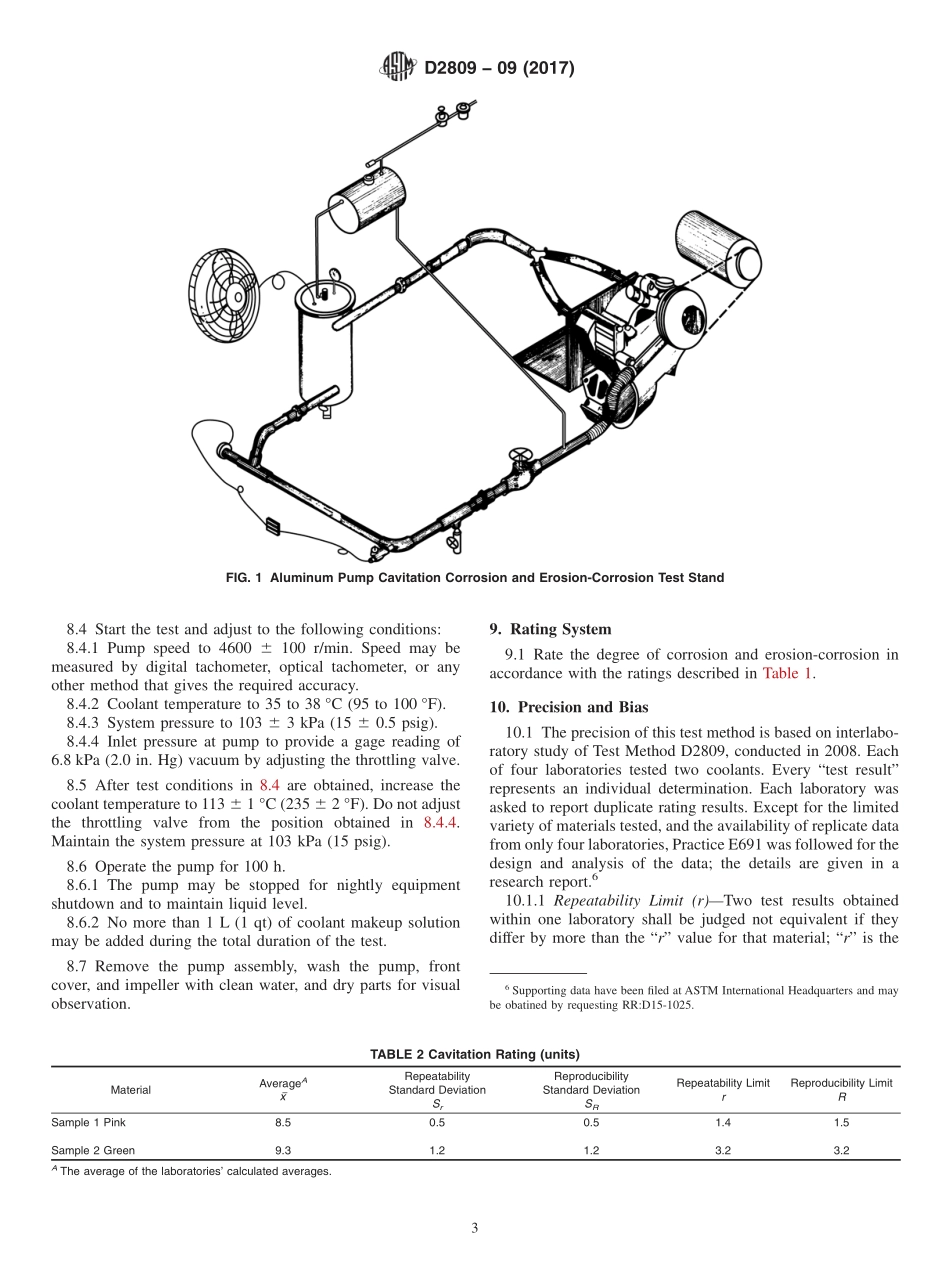

Designation:D2809−09(Reapproved2017)StandardTestMethodforCavitationCorrosionandErosion-CorrosionCharacteristicsofAluminumPumpsWithEngineCoolants1ThisstandardisissuedunderthefixeddesignationD2809;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoverstheevaluationofthecavitationcorrosionanderosion-corrosioncharacteristicsofaluminumautomotivewaterpumpswithcoolants.NOTE1—Duringthedevelopmentofthistestmethod,itwasfoundthatresultsobtainedwhentestingtwo-phasecoolantsdidnotcorrelatewithresultsfromfieldtests.Therefore,thetestmethodcannotberecommendedasbeingasignificanttestfordeterminingcavitationeffectsoftwo-phasecoolants.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.Specificwarningstatementsaregivenin5.2.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D1176PracticeforSamplingandPreparingAqueousSolu-tionsofEngineCoolantsorAntirustsforTestingPurposesE177PracticeforUseoftheTermsPrecisionandBiasinASTMTestMethods2.2ASTMAdjunct:3Pumpteststand(7drawingsandBillofMaterials)3.SummaryofTestMethod3.1Thistestmethodconsistsofpumpinganaqueouscoolantsolutionat113°C(235°F)throughapressurized103-kPa(15-psig)simulatedautomotivecoolantsystem(Note2).Analuminumautomotivewaterpump,drivenat4600r/...