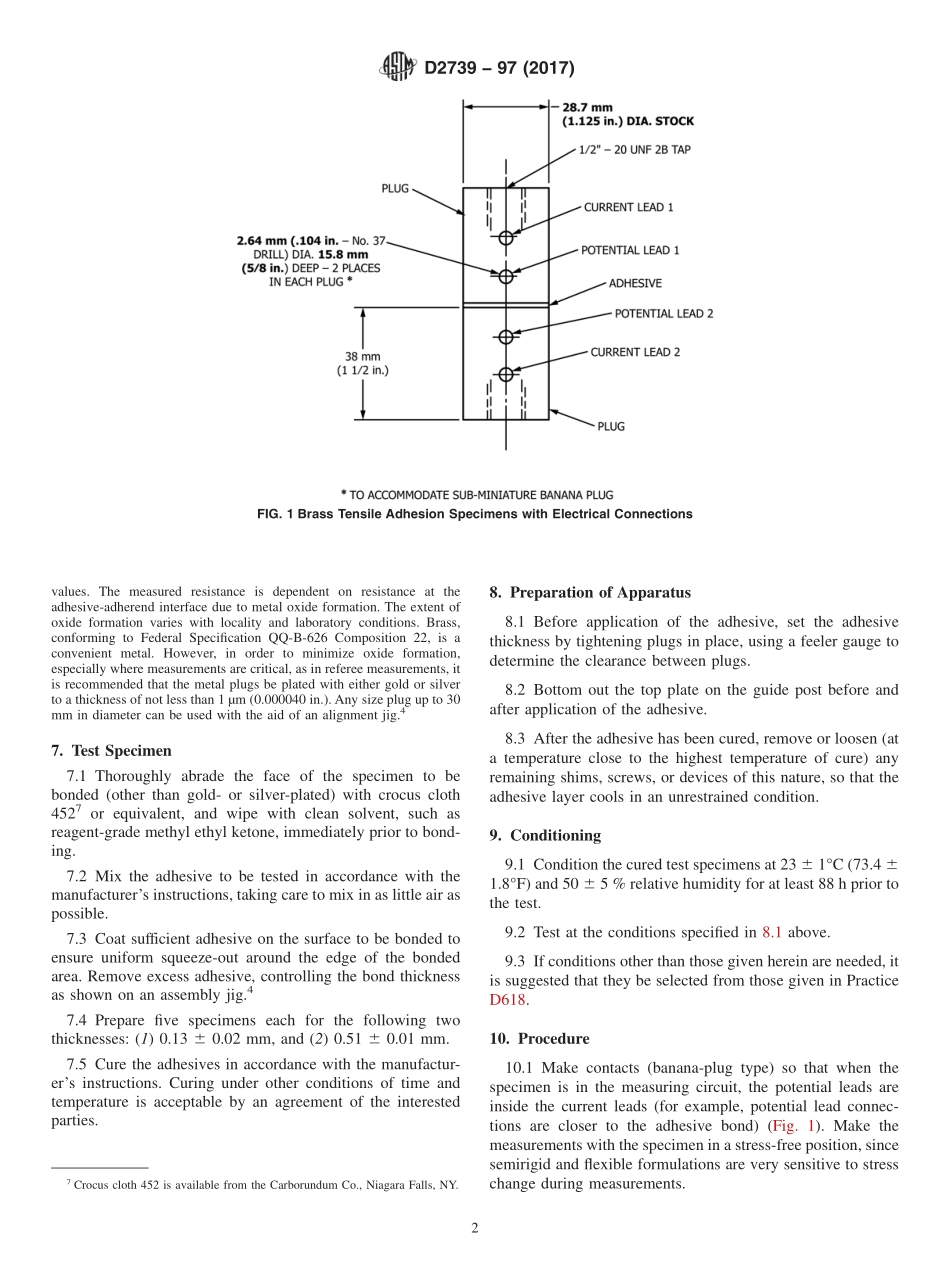

Designation:D2739−97(Reapproved2017)StandardTestMethodforVolumeResistivityofConductiveAdhesives1ThisstandardisissuedunderthefixeddesignationD2739;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationofthevolumeresistivityofresin-basedconductiveadhesivesinthecuredcondition.Thetestismadeonathinadhesivelayeraspreparedinabondedspecimen.Thistestmethodisusedforconductiveadhesivesthatarecuredeitheratroomtemperatureoratelevatedtemperatures.1.2ThevaluesstatedineitherSIorotherunitsshallberegardedseparatelyasstandard.SIequivalentstoscrewthreadsareshowninthefigures.1.3Thisstandarddoesnotpurporttoaddressthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafety,health,andenvironmentalpracticesanddeterminetheappli-cabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D618PracticeforConditioningPlasticsforTestingD907TerminologyofAdhesives2.2FederalSpecification:QQ-B-626Composition2232.3ASTMAdjuncts:AssemblyJig43.Terminology3.1Definitions:3.1.1ManytermsinthistestmethodaredefinedinTermi-nologyD907.3.1.2conductivity,n—theratioofthecurrentdensitycarriedthroughaspecimentothepotentialgradientparallelingthecurrent.Thisisnumericallyequaltotheconductancebetweenoppositefacesofaunitcubeofliquid.Itisthereciprocalofresistivity.D2864,D273.1.3resistivity,volume,n—theratiooftheelectricpotentialgradienttothecurrentdensitywhenthegradientisparalleltothecurrentinthematerial.D1566,D114....