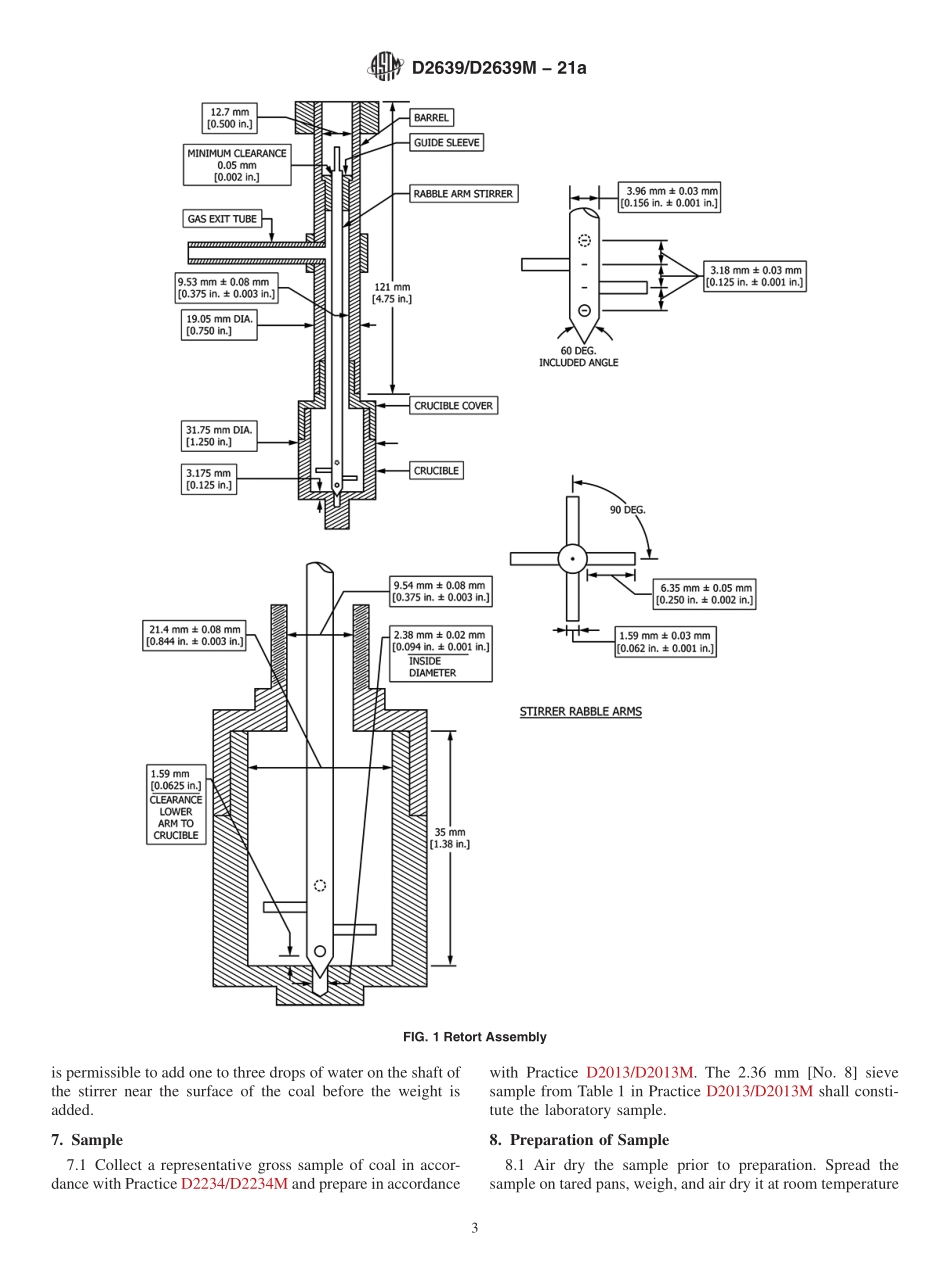

Designation:D2639/D2639M−21aStandardTestMethodforPlasticPropertiesofCoalbytheConstant-TorqueGieselerPlastometer1ThisstandardisissuedunderthefixeddesignationD2639/D2639M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversarelativemeasureoftheplasticbehaviorofcoalwhenheatedunderprescribedconditions.Thistestmethodmaybeusedtoobtainsemiquantitativevaluesoftheplasticpropertiesofcoalsandblendsusedincarbonizationandinothersituationswheredeterminationofplasticbehaviorofcoalsisofpracticalimportance.1.2Units—ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemarenotnecessarilyexactequiva-lents;therefore,toensureconformancewiththestandard,eachsystemshallbeusedindependentlyoftheother,andvaluesfromthetwosystemsshallnotbecombined.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D2013/D2013MPracticeforPreparingCoalSamplesforAnalysisD2234/D2234MPracticeforCollectionofaGrossSampleofCoal3.Terminology3.1Definitions:3.1.1breaking,v—freespinningbehaviorofcoal,eitherbyanabruptchangetorotatingatmaximummotorspeedorbyabruptchangesinrotation,whichoccursasaresultofamoltenballofcoalformingaroundthebaseofthestirrer,andwhichmakesreportingofthetruemaximumfluidityofthecoaldifficult....