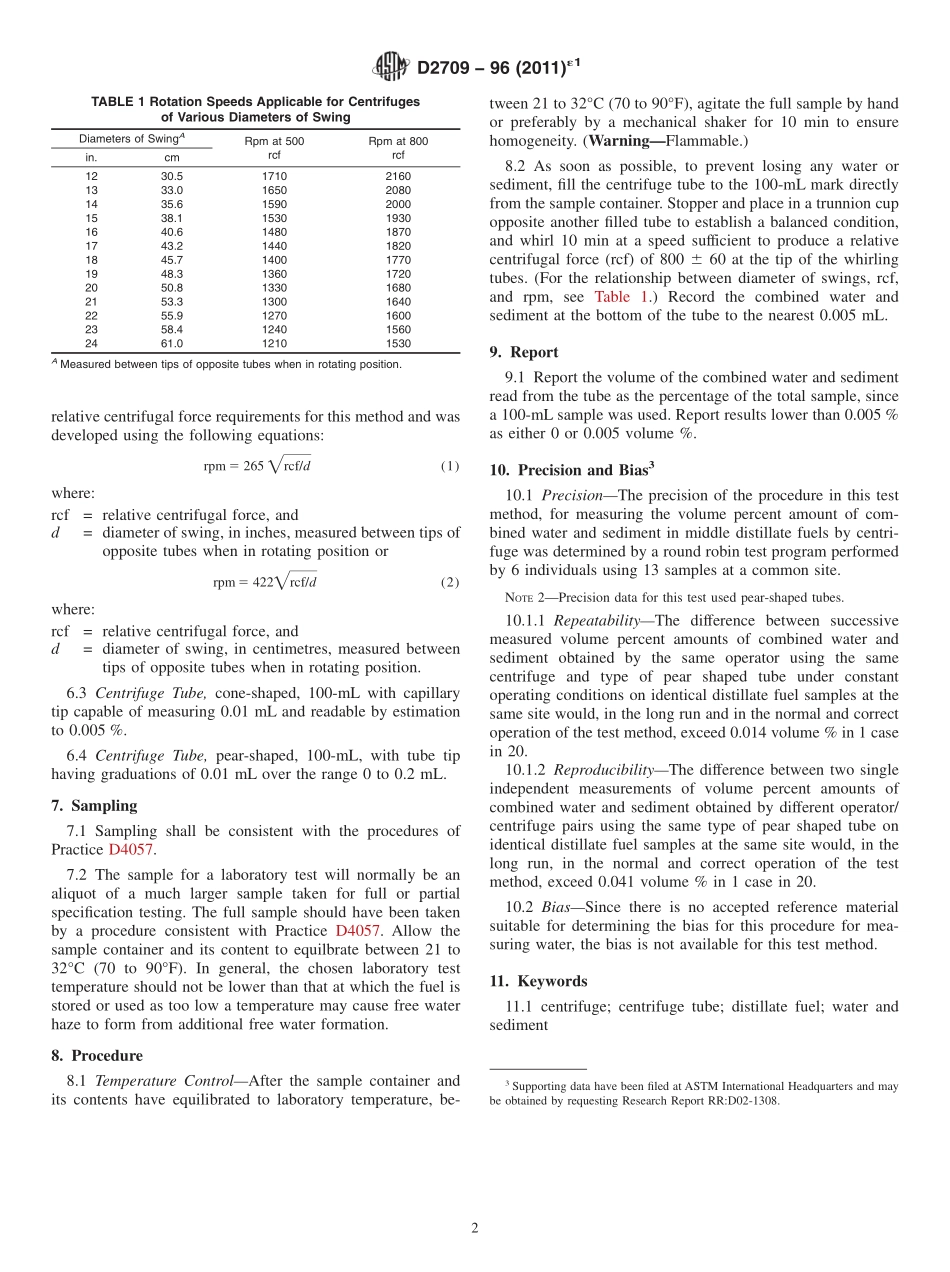

Designation:D2709−96(Reapproved2011)´1StandardTestMethodforWaterandSedimentinMiddleDistillateFuelsbyCentrifuge1ThisstandardisissuedunderthefixeddesignationD2709;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.´1NOTE—Addedpartofspeechtotermin3.1.1editoriallyinMay2011.1.Scope1.1Thistestmethodcoversthedeterminationofthevolumeoffreewaterandsedimentinmiddledistillatefuelshavingviscositiesat40°C(104°F)intherangeof1.0to4.1mm2/s(1.0to4.1cSt)anddensitiesintherangeof770to900kg/m3.NOTE1—FuelscorrespondingtoSpecificationD975Grades1Dand2D,SpecificationD2880Grades0-GT,1-GTand2-GT,andSpecificationD3699Grades1-Kand2-Kwillusuallyfallinthisviscosityanddensityrange.TestMethodD1796isintendedforhigherviscosityfueloils.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D396SpecificationforFuelOilsD975SpecificationforDieselFuelOilsD1796TestMethodforWaterandSedimentinFuelOilsbytheCentrifugeMethod(LaboratoryProcedure)D2880SpecificationforGasTurbineFuelOilsD3699SpecificationforKerosineD4057PracticeforManualSamplingofPetroleumandPetroleumProducts3.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1distillatefuel,n—avirginorcrackedorblendofvirginandcrackeddistillatehavingaflashpointgreaterthan38°C.4.SummaryofTestMethod4.1A100-mLsampleoftheundilutedfueliscentrifugedatarelativecentrifugalforceof800for10minat21to32°C(70to90°F)inacentrifugetubereadableto0.005mLandmeasurableto0....