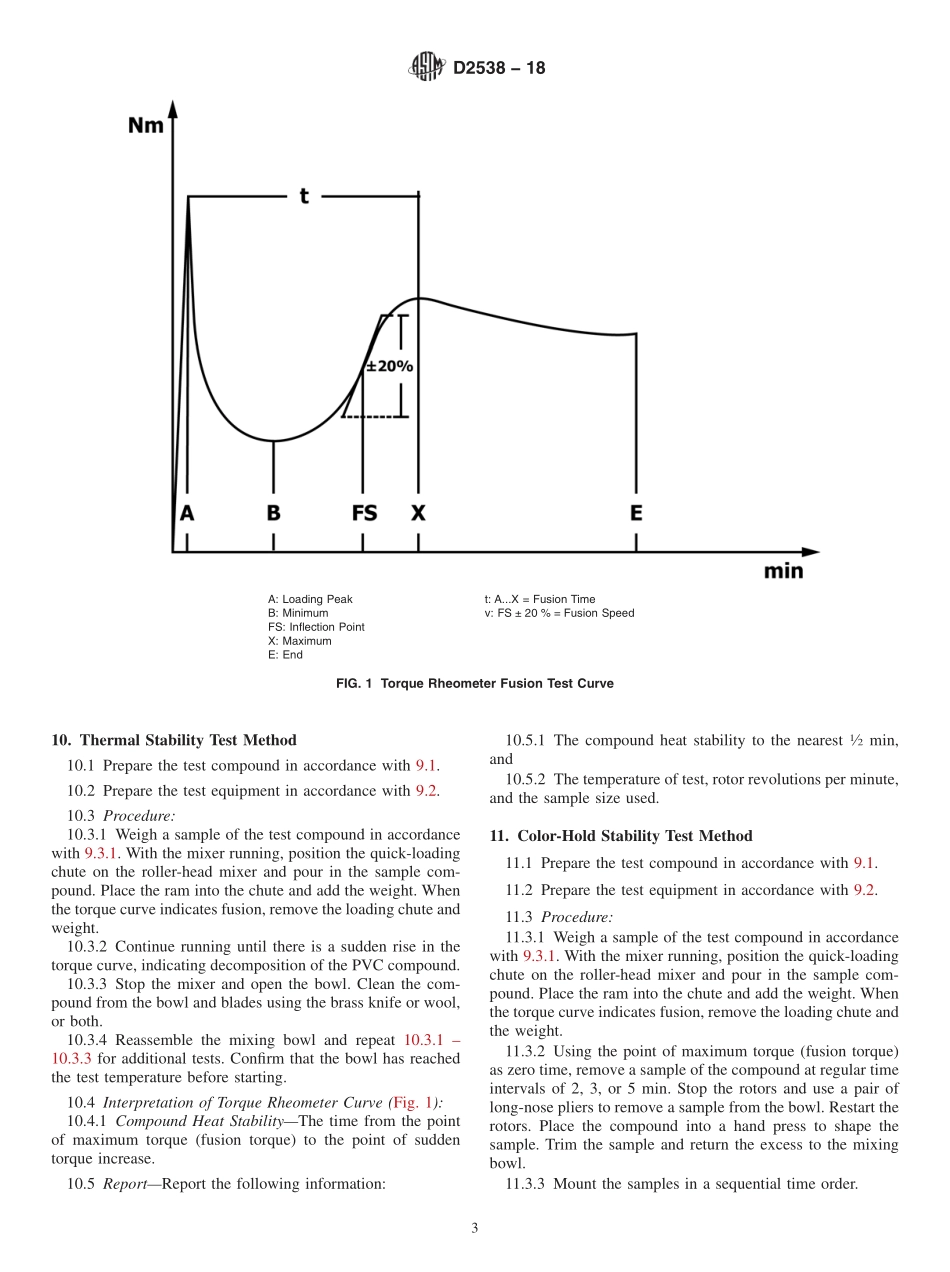

Designation:D2538−18StandardPracticeforFusionofPoly(VinylChloride)(PVC)CompoundsUsingaTorqueRheometer1ThisstandardisissuedunderthefixeddesignationD2538;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticecoverstherelativefusioncharacteristicsofpoly(vinylchloride)compounds.1.2Thetestproceduresappearinthefollowingorder:SectionFusionTest9ThermalStabilityTest10Color-HoldStabilityTest11ShearStabilityTest121.3ThevaluesstatedinSIunitsaretoberegardedasthestandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.SpecifichazardsstatementsaregiveninSection8.NOTE1—TherearenoISOstandardscoveringtheprimarysubjectmatterofthisASTMstandard.1.5Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D883TerminologyRelatingtoPlasticsD1600TerminologyforAbbreviatedTermsRelatingtoPlas-ticsE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.Terminology3.1Definitions—DefinitionsareinaccordancewithTermi-nologiesD883andD1600unlessotherwiseindicated.4.SummaryofPractice4.1Asampleofpowder-mixcompoundisaddedtotheheatedrollermixerchamberandistransformedintoafusedmass.4.2Theresultingtorquecurvecanbeusedtodeterminetherelativefusiontimeandfusioncharacteristics.5.SignificanceandUse5.1WhenPVCcompoundsaremixedunderappropriateconditionsofheatandshear,afusedmassisproduced.Thismass...